{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

Cat. Nr.:

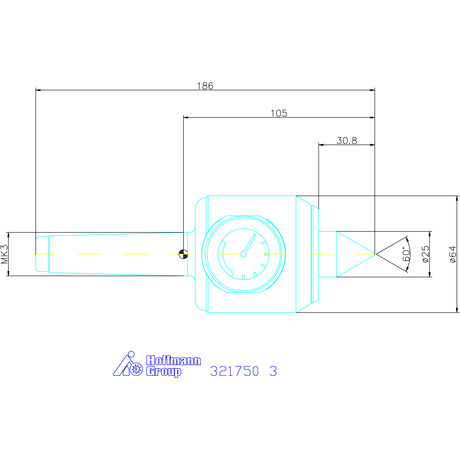

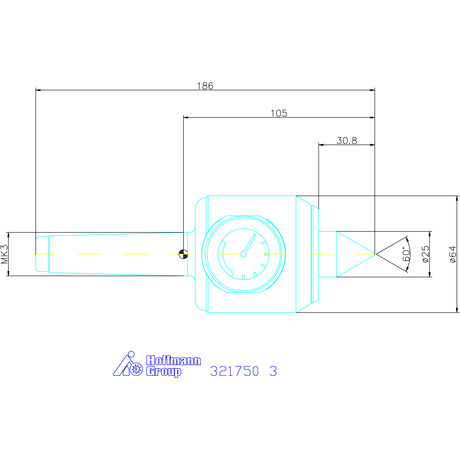

| Morse taper | MT3 | |

| Body ⌀ D | 64 mm | |

| Reach B | 105 mm | |

| largest centre point ⌀ 60° A | 11 mm | |

| largest centre point ⌀ 30° A | 25 mm | |

| maximum radial run-out | 0.01 mm | |

| for workpiece weight | 400 kg | |

| maximum axial clamping force | 550 daN | |

| Type of product | Centring drill |

| Article number |

321750 3

Copy |

|

| EAN / GTIN |

4019208017112

Copy |

|

| Manufacturer number |

060798

Copy |

|

| Manufacturer/responsible person | Röhm GmbH, Heinrich-Röhm-Straße 50, 89567 SONTHEIM/BRZ, Germany, www.roehm.biz |