ESD basics and the optimum protection for you

With effective ESD protection, you won’t have a hair-raising experience

Electrostatic discharge is a good example of a minor detail that can have major consequences. Also known by the abbreviation ESD, it describes the uncontrolled equalisation of electrical charge between two differently charged objects.

The basic principle is that where there is no charge, there can be no discharge.

Many electrostatic discharges are so low that they go unnoticed by humans – humans do not perceive them until they reach around 3,000 V. However, you still need to take care because just 30 V is enough for electrostatic discharge to cause major damage, e.g. when manufacturing semiconductors.

If we take a look at the typical causes, it becomes clear that you need to assume the presence of ESD virtually everywhere, especially in industrial environments:

- Unrolling sticky tape

- Moving conveyor belts

- Walking across plastic flooring

- Friction against synthetic clothing

- Moving plastic containers

That’s why it’s crucial to prevent such hazards in your electronics manufacturing areas. If you arm yourself properly against electrostatic discharge, you can safeguard the quality of your components and maintain your reputation. Choose ESD-proof equipment – particularly in manufacturing areas where movements are an intrinsic part of your value chain.

Watch out for hidden risks

Electrostatic discharge is characterised by a low current, which virtually rules out the potential for bodily harm. Depending on the level of voltage concerned, electrostatic discharge is

- noticeable as from 3,000 V

- audible as from 5,000 V

- visible as from 10,000 V in the form of a spark or flash.

Low humidity encourages the formation of electrostatic charges, so an effective preventative measure is simply ensuring that the humidity level in your manufacturing areas remains between 40% and 60%.

What your good reputation has to do with EPAs

An EPA (Electrostatic Protected Area) provides effective protection against damage caused by electrostatic discharge. All precautionary measures are taken in these areas to be able to work with electrostatically sensitive assemblies without damaging them.

Why effective protection is crucial

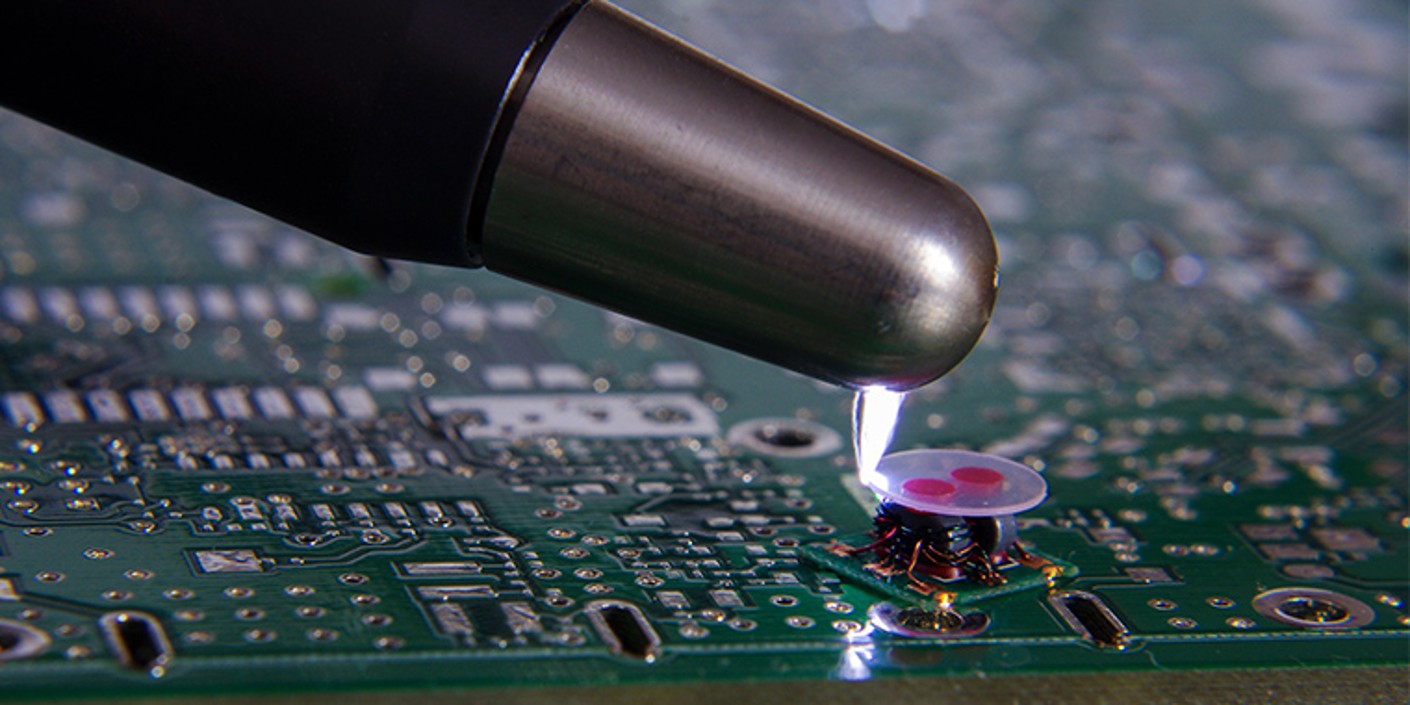

ESD almost always occurs under the radar. Components that have been damaged by ESD are visually indistinguishable from undamaged ones. The fact that ESD can affect functionality and service life to such an extent without anyone noticing makes protective measures an absolute must in electronics manufacturing and related workplaces.

Although people themselves are usually not at risk, ESD can very easily have a major impact on the quality of your components, as there may well be voltage levels of over 10,000 volts depending on the working environment. A good example is plastics, like you can find at many points in the manufacturing process. They have very good electrostatic charging properties on account of their high surface resistance. As a result, the surface potential of a conventional plastic transportation box can be up to 20,000 volts, greatly increasing the risks for the electronic components and parts inside. And you can’t forget the air conditioning system either. Whilst it might be a boon for your workforce in summer, it poses a risk to electronic components as the lower the humidity, the greater the risk of electrostatic charges. That’s reason enough to keep the humidity level between 40% and 60%.

A minor detail with major consequences: how inadequate ESD protection manifests itself

Electronic components such as semiconductor assemblies can incur both visible and invisible damage. Please be aware that damage sometimes will not become apparent until the component has been integrated into the final product and this has been in operation for a certain period of time.

In practice, this means:

- Product failures once installed

- Complaints

- Costs for repairs and replacements

- Loss of reputation as an electronics supplier

- Loss of customers

Follow the principle of:

“Where there is no charge, there can be no discharge”. Making as few movements as possible and using ESD-proof equipment minimises the risk of static charges caused by personnel.

Got a question about PPE, workstations and storage equipment or ESD tools?

The Hoffmann Group provides you with everything from a single source:

- We would be pleased to help you choose the right products in line with your ESD inspection plan

- We can provide the help you need to set up your EPA as stipulated in your ESD inspection plan

You can reach us by telephone, e-mail or fax.

To consultation

To consultation