ESD basics and the optimum protection for you

What is ESD?

ESD is short for electrostatic discharge. Large differences in potential (different voltages) cause a short electrical current – either in the form of a spark or disruptive discharge.

Depending on the voltage – i.e. the voltage figure – this phenomenon can be

- felt (from 3,000 volts)

- heard (from 5,000 volts) and

- seen in the form of a spark or flash (from 10,000 volts).

For a human to perceive static discharge, it needs to have reached around 3,000 volts. In comparison, 30 volts are already enough to destroy a semiconductor assembly.

What causes electrostatic charge?

Electrostatic charge occurs when electric charges are separated. This happens, for example, when two different types of material are rubbed against each other or separated.

It often occurs in normal everyday situations, such as when walking across a carpet in plastic-soled shoes. This leads to predominately negative electric charges that spread across the entire object or body being absorbed. Should the object or body then come into contact with another conductive object or grounding (e.g. a heating device), this charge abruptly flows off.

Examples of separated charges:

- Walking across plastic flooring

- Friction against synthetic clothing

- Moving plastic containers

- Unrolling sticky tape

- Moving conveyor belts

Electrostatic charge can be caused by reduced levels of humidity in the air, which is why air humidity should be between 40% and 60%.

When is ESD dangerous?

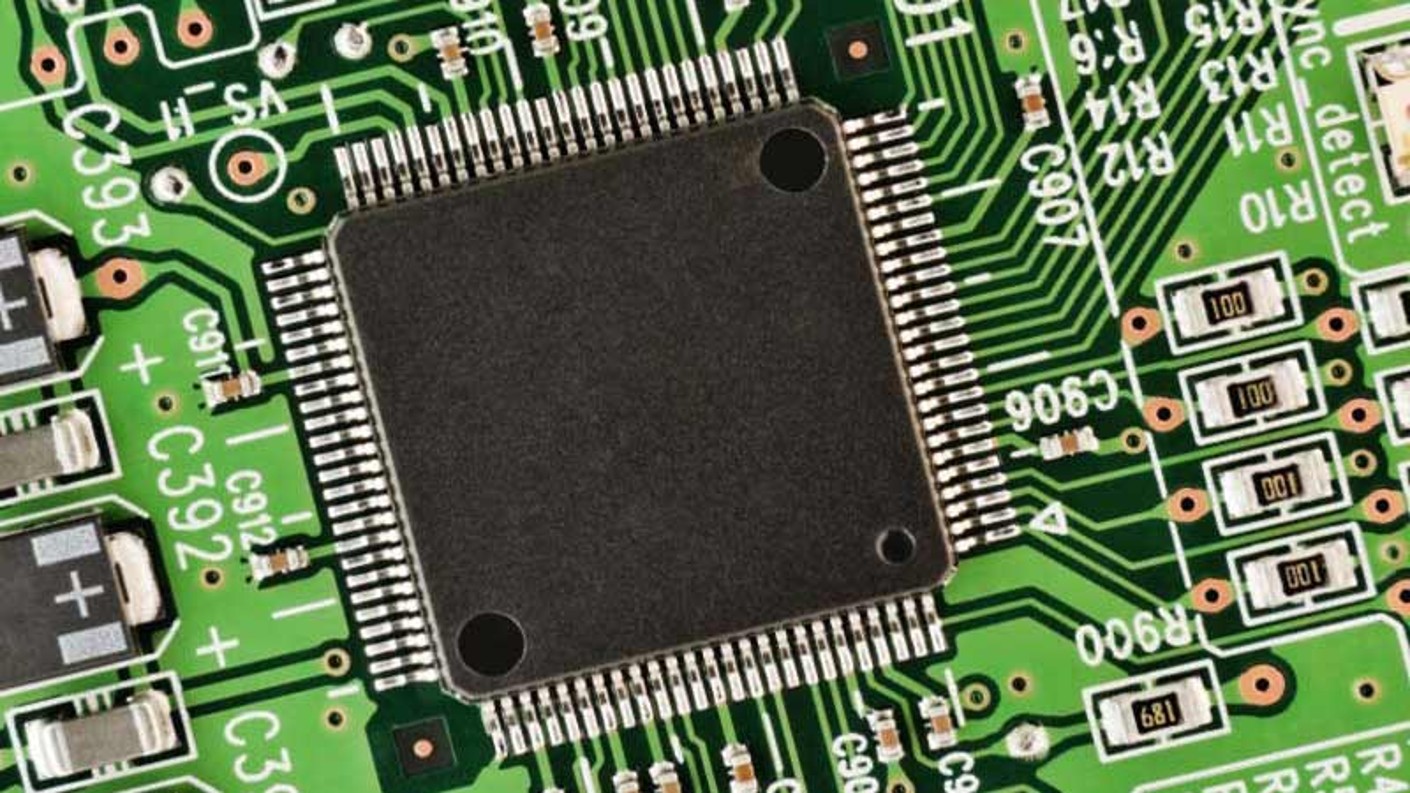

ESD does not normally pose any risk to humans. However, electrostatic discharge could be dangerous in manufacturing operations within the electronics industry.

Uncontrolled electrostatic discharge can lead to total failures as well as hidden defects in electronic assemblies (semiconductor devices), which can result in high costs with regard to:

- Product failures

- Complaints

- Repair and replacement costs

- Loss of reputation

- Loss of costumers

In modern working areas, it is quite easy for voltages of over 10,000 volts to occur. Plastics are especially susceptible to being charged with electrostatic energy, due to their high surface resistance level. For example, the surface potential of a generic plastic box can be up to 20,000 volts – a risky environment for electronic assemblies being transported inside.

Assemblies that are at risk from electrostatic charge when being processed or transported are classed as ESDS (electrostatic discharge sensitive devices) and are marked with the following symbol:

Protection against ESD

An ESD protected area, also known as an EPA (electrostatic protected area), provides effective protection against damage caused by electrostatic discharge. All precautionary measures are taken here to be able to work with electrostatically sensitive assemblies without damaging them.

An extensive ESD protected area (EPA) comprises the following areas (minimum requirements according to DIN EN 61340-5-1):

Follow the principle:

“Where there is no charge, there can be no discharge”. Making as few movements as possible and using ESD-proof equipment keeps the risk of static charge caused by people to a minimum.

Do you have any questions? Do you need an ESD consultant?

The Hoffmann Group provides you with everything from a single source:

- We can develop a tailor-made EPA for you

- And provide you with the appropriate products for dealing with ESD-sensitive assemblies.

You can reach us by telephone, e-mail or fax.

You can find an explanation of all of the most important terms concerning the topic of ESD/EPA here:

To ESD consultation

To ESD consultation