GARANT Automation Basic loading systems

Equip an older machine tool with an automation system

In the video we show you, how an older Mazak QuickTurn 200 M (built in 2003) was equipped with the GARANT Automation Basic loading system at our customer Horst und Heinrich Michler GmbH.

Do you also have an existing machine and are thinking about adding a semi-automated system? Simply contact us.

Standout features of the GARANT Automation loading system

How using loading robots unlocks even greater manufacturing potential and boosts machine capacity

Today, a number of semi-automated production processes are already widely known, for example those that make life easier for production floor managers and machine operators. These range from automated tool changes on the machine to dual-spindle lathes and even simultaneous tooling while the machine is running thanks to machines equipped with automated pallet changers. These kinds of automation already increase productivity without impairing quality.

But if you’re looking to reduce costs per unit and want to ensure efficient deployment of personnel over the long term, you can now turn to our GARANT Automation Basic loading system.

Your new team member strengthens your team

The GARANT Automation Basic loading system strengthens and relieves your team. So your production is fit for the challenges of the constantly changing market.

- By (semi-)automating these separate process steps, you’ll be meeting your demand today, be set up for future requirements and increasing your capacities considerably – and you’ll still be turning a profit.

- Automated loading for small-lot or custom-piece production makes it possible to expand capacities without having to hire extra personnel – and is possible even on machines that you’ve already had in use for a while.

Load and unload machines automatically with GARANT Automation Basic loading systems

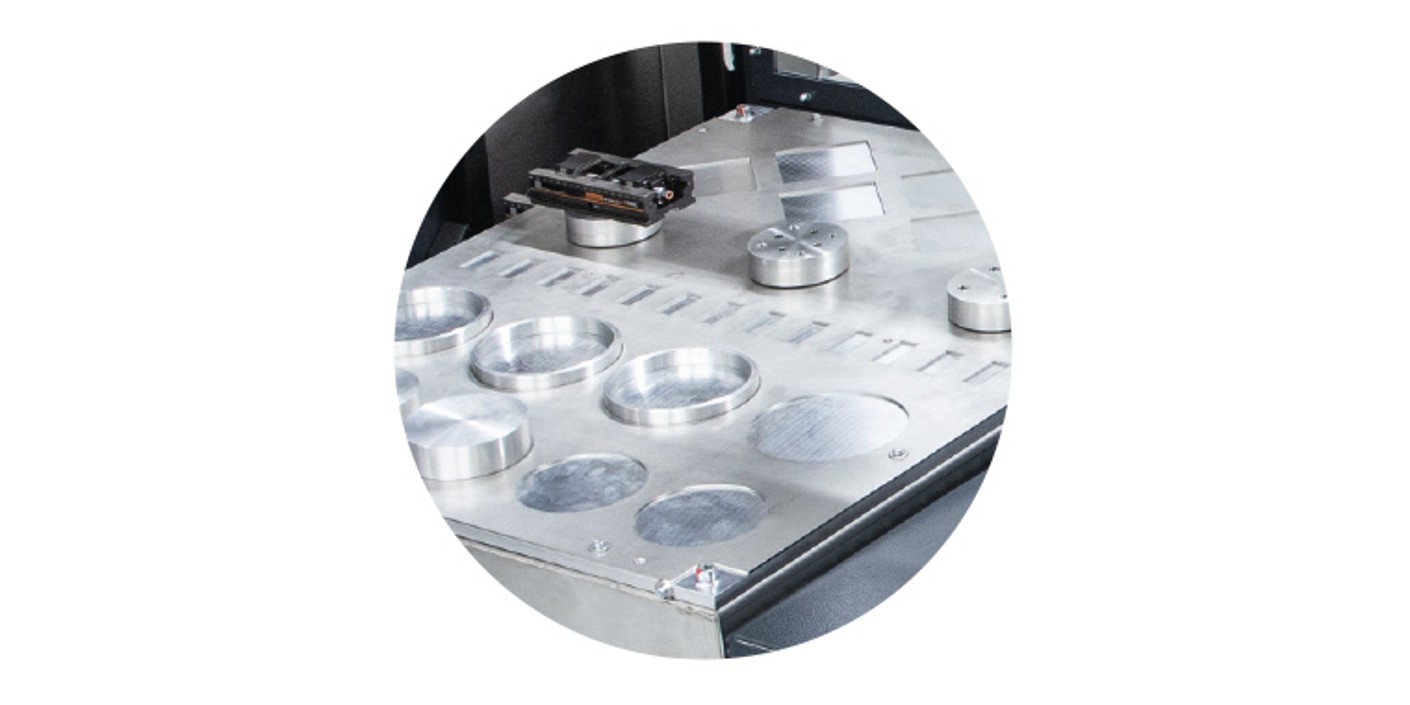

The GARANT Automation Basic loading system is designed for use with lathes, milling machines and machining centres. The loading systems load and unload blank parts, finished parts and vices in your CNC machines. The solid base frame, stable construction and safety devices ensure safe operation as well as simple and effortless loading and unloading of the tool store.

- For use on turning, milling and machining centres

- Safe operation thanks to solid base frame, sturdy design and protective devices

- Easy loading and unloading of the tool magazine

7 advantages of the GARANT Automation loading system

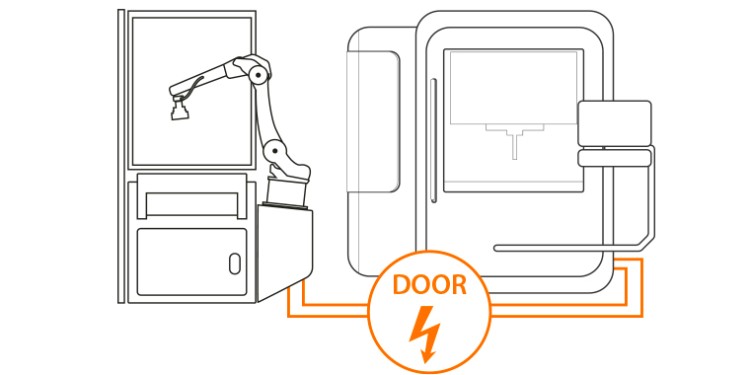

- No automation interface required

- No automatic door required

- No robot programming knowledge required

- Existing and new machines can be automated

- No rotary feed-through union required (media transfer by robot)

- Can be integrated within a few days (quick start to production)

- One contact person for all matters (automation, machining process, workstation etc.)

From the GARANT Basic base model to the GARANT Basic Plus as your perfect solution

GARANT Basic is the most cost-effective and fastest way to automate your machine tool. Designed specifically to ensure simple clamping, it is easier than ever to program. Change your jobs in minutes so you can remain highly flexible.

Automation machine

- CNC lathes and milling and machining centres

Components

- Any type of blank and semi-finished parts up to a maximum of 10 kg

- Xtric vice handling up to max. 10 kg

Control

- One actuator

- Operation of pneumatic clamping devices

Software

- Load and unload a clamping point

- Stack function

- Push-on function

- Blow-off function

Gripper

- Centric gripper

- Parallel gripper

With the high flexibility of the GARANT Basic Plus system, all doors are open to you. Whether turning or milling, whether main spindle or secondary spindle, whether a round or angular component - GARANT Basic Plus can be easily adapted to your component.

Automation machine

- CNC lathes and milling and machining centres

Components

- Any type of blank, semi-finished and finished parts up to a maximum of 10 kg

- Xtric vice handling up to max. 10 kg

Control

- Up to two actuators

- Operation of pneumatic clamping devices

Software

- Load and unload 1 clamping point

- Loading only

- Unloading only

- Process 1st and 2nd side

- Stack function

- Turning station

- Storage in alternative location

- Push-on function

- Blow-off function

Gripper

- Centric gripper

- Parallel gripper

- Vacuum gripper

And on to your bespoke GARANT Basic Individual automation solution

.

The GARANT Basic Individual is based on the GARANT Basic Plus and incorporates the same functions. It can be extended with the ICONIC packages to suit your applications. With the GARANT Basic Individual system, the system can be adapted to your individual needs by using various packages.

Expand your GARANT loading system with our ICONIC packages to meet your individual production needs:

(1) Specific

- Fixed electrical connection between the system and machine tool

- Use of machine functions (door pneumatics etc.)

- Adaptation of robot program and additional installation work

- CE type approval

(2) Protection

- Complete protective enclosure with closed door (no need for integrated safety guarding or zone scanner)

- Adjustment on site incl. robot program

- CE type approval

(3) Free

- Installation of free-standing system, detached from the machine tool, incl. second scanner (no protective enclosure)

- Up to three actuators

- Adjustments on site incl. robot program

- CE type approval

Our customers have been won over by the GARANT Automation loading system

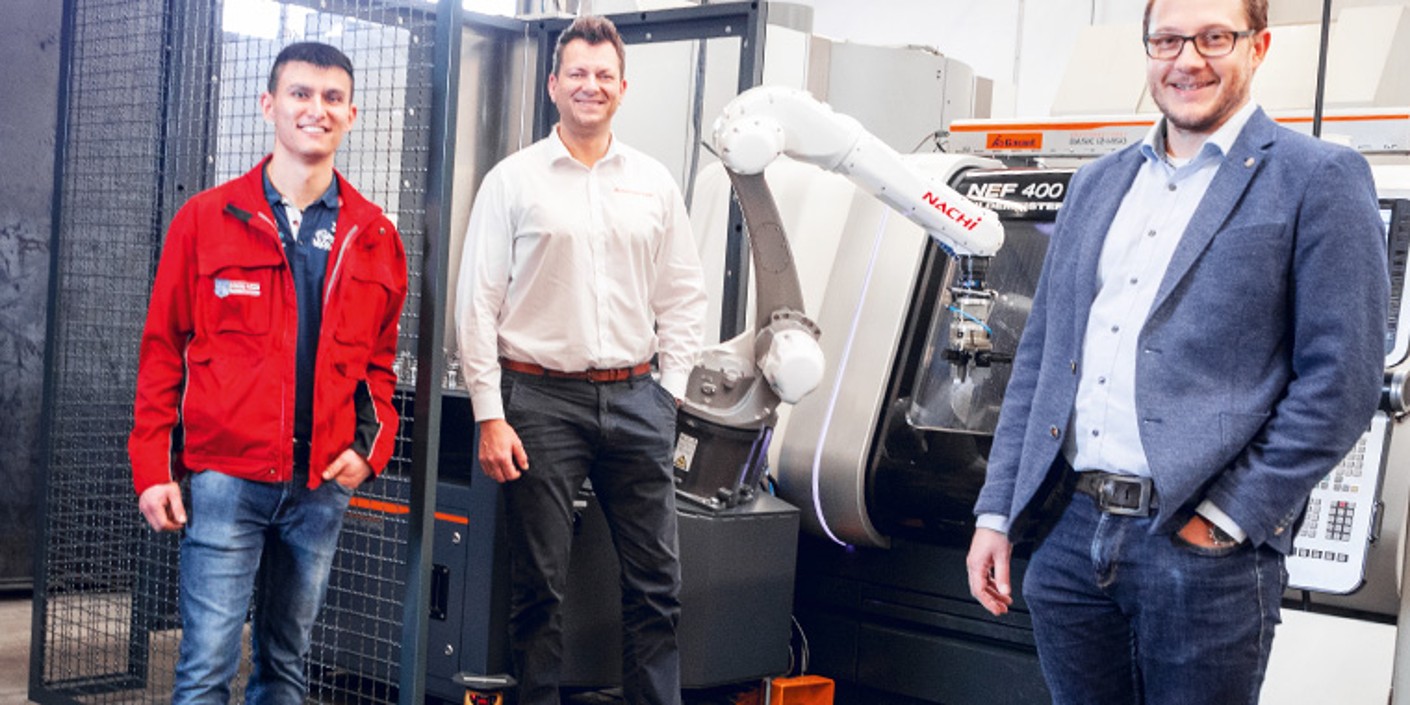

Turnover boosted by 30 to 40 percent

Going into series production was a risk for Matthias Schöwel and Christoph Schwarzmüller from MCS Zerspanungstechnik GBR. But their decision to use the GARANT Automation loading system paved the way for larger jobs and a better work-life balance.

The GARANT Automation Basic loading systems come with an extensive range of accessories

- GARANT Auto Door (automated door opening for your machine tool)

- Gripper assemblies

- Gripper systems and clamping technology from SCHUNK

- Gripper finger set

- Finger blanks

- Gripper finger positioning aid

- Pressure pieces

- Variable grid plate

- Stacking pins

- Angular workpiece stop

- Spacer set

- Gripper quick-change coupling

- Turning unit

- Workbenches

More efficient production in next to no time

Johann Schild Herstellung + Handels GmbH had big plans – and has made great progress since commissioning our GARANT Automation Basic loading system: in no time at all, they have become faster and more efficient, with improved production reliability.

We’re by your side whatever your requirements: semi-automation, process optimisation or autonomous production. Find out more here:

Hoffmann Group product ranges covered together with automation:

If you, too, have free or unused machine capacities, GARANT Automation is easy and fast to integrate into your production facilities.

- Set up for future requirements

- Reduce costs per unit

- Assure work/life balance

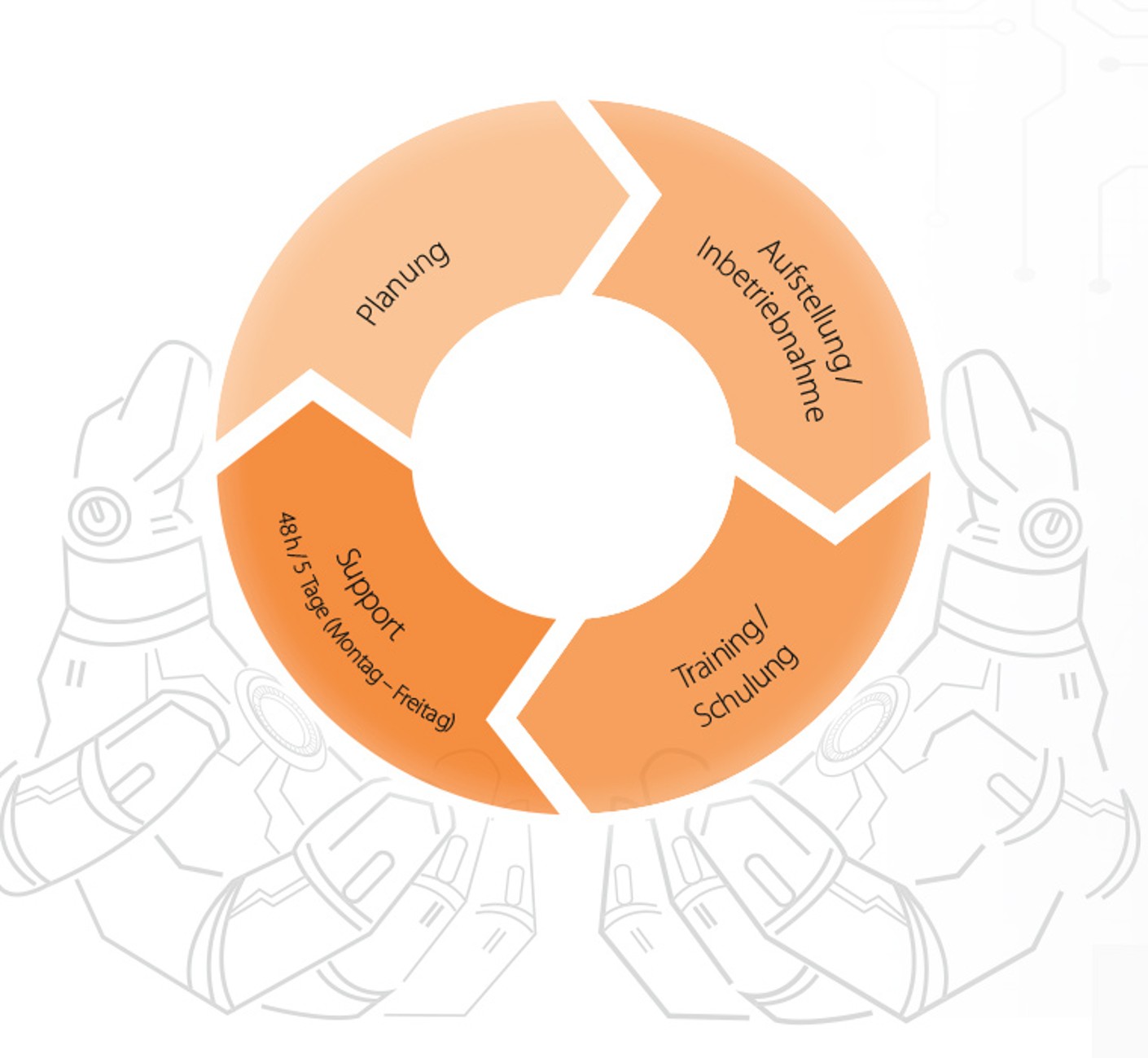

Our range of services

Loading and unloading’s never been easier thanks to GARANT Automation Loading System BASIC.

What we offer: All-around service from a single source.

- We’ll plan your project together with you.

- We’ll handle installation and commission your automation solution.

- You’ll get comprehensive training and instruction documents for yourself and your workforce.

- On top of that, we offer a 48-hour service turnaround, five days of the week.

Like what we’re saying?

Book consultation now!

We’ll give you detailed advice on GARANT Automation loader robots so we can find precisely the solution you need together.

+49 89 8391 9930

connectedmanufacturing@hoffmann-group.com