GARANT disc brushes: deburring with a perfect finish during automated finishing

Disc brushes are optimal for machining centres and robot cells

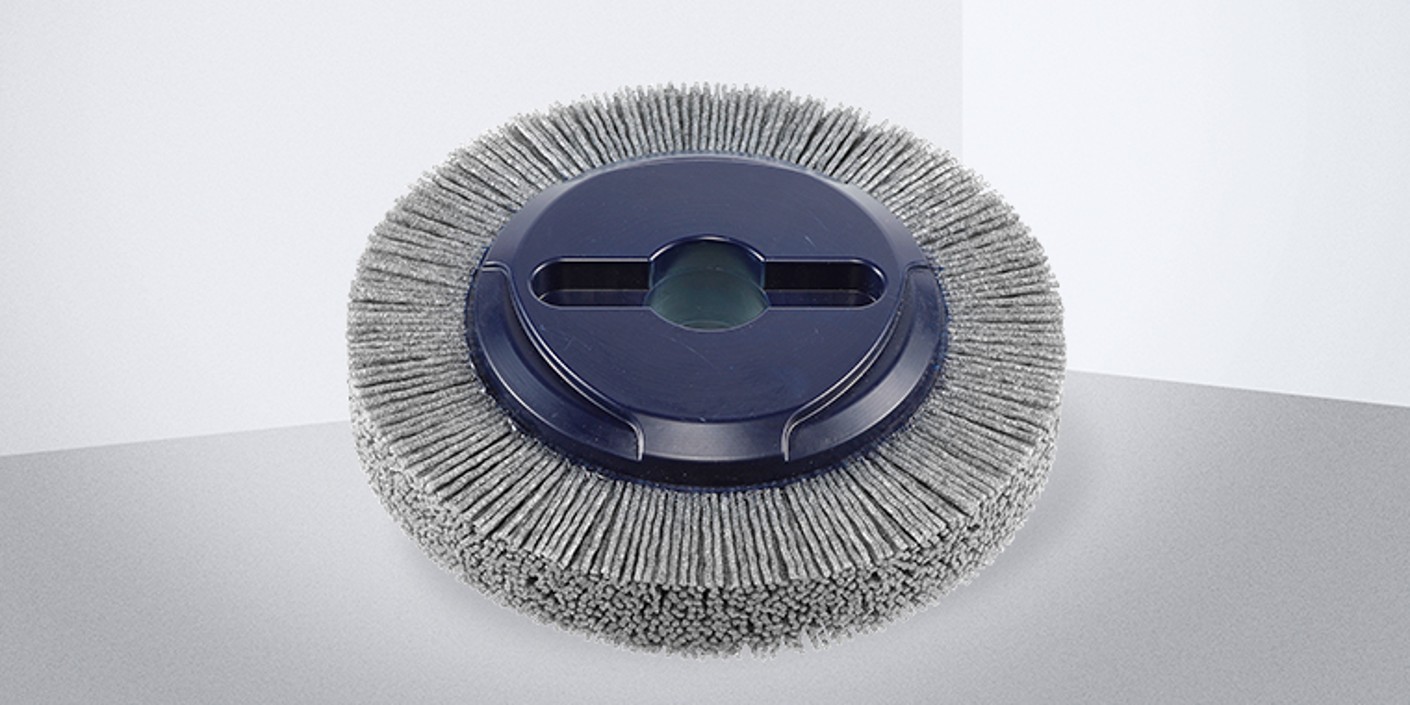

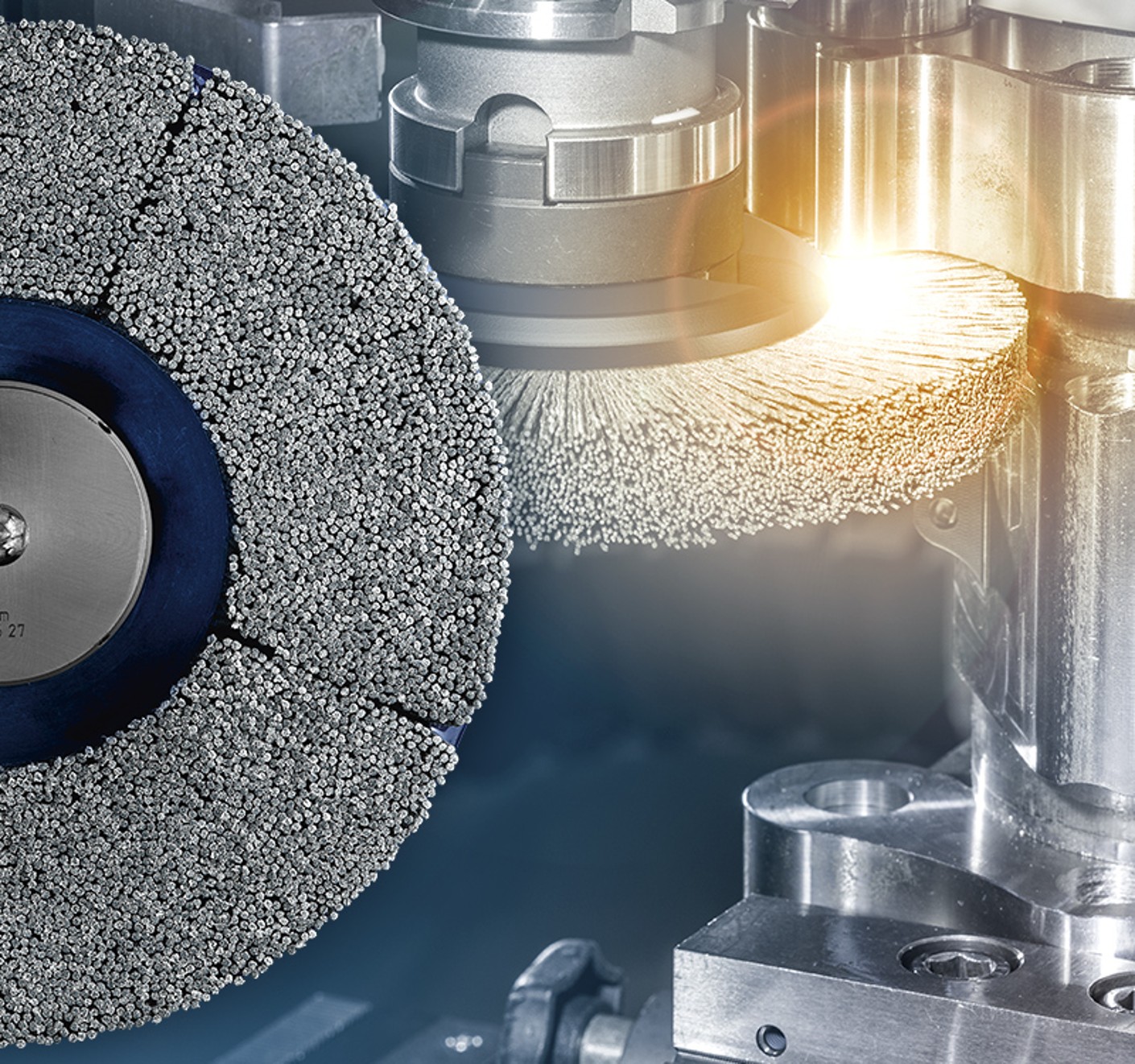

GARANT disc brushes with bristles right to the edge of the brush offer new possibilities for automated surface finishing. They are outstandingly suitable for processing aluminium.

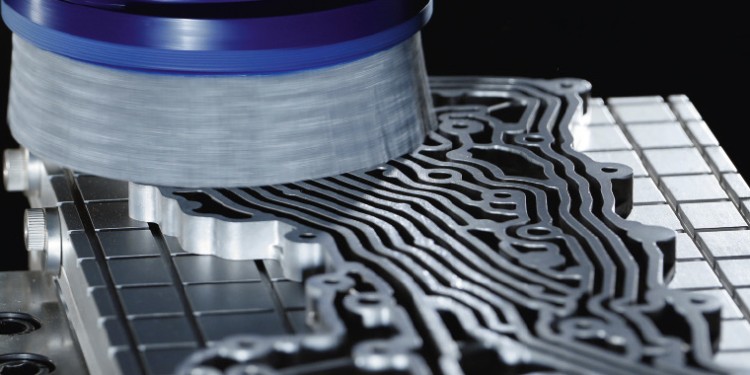

GARANT disc brushes are high-tech brushes for use on CNC machines or in robot cells. They are particularly suitable for use when workpieces must be finished quickly and reliably by an automated and reproducible process after the machining process has been completed. The main application is in precise deburring, edge rounding, surface finishing of precision parts without changing the geometry of the workpiece.

With a disc brush you have hundreds of flexible bristles in use at the same time. By this means even complex components can quickly be deburred.

Application recommendations for GARANT disc brushes

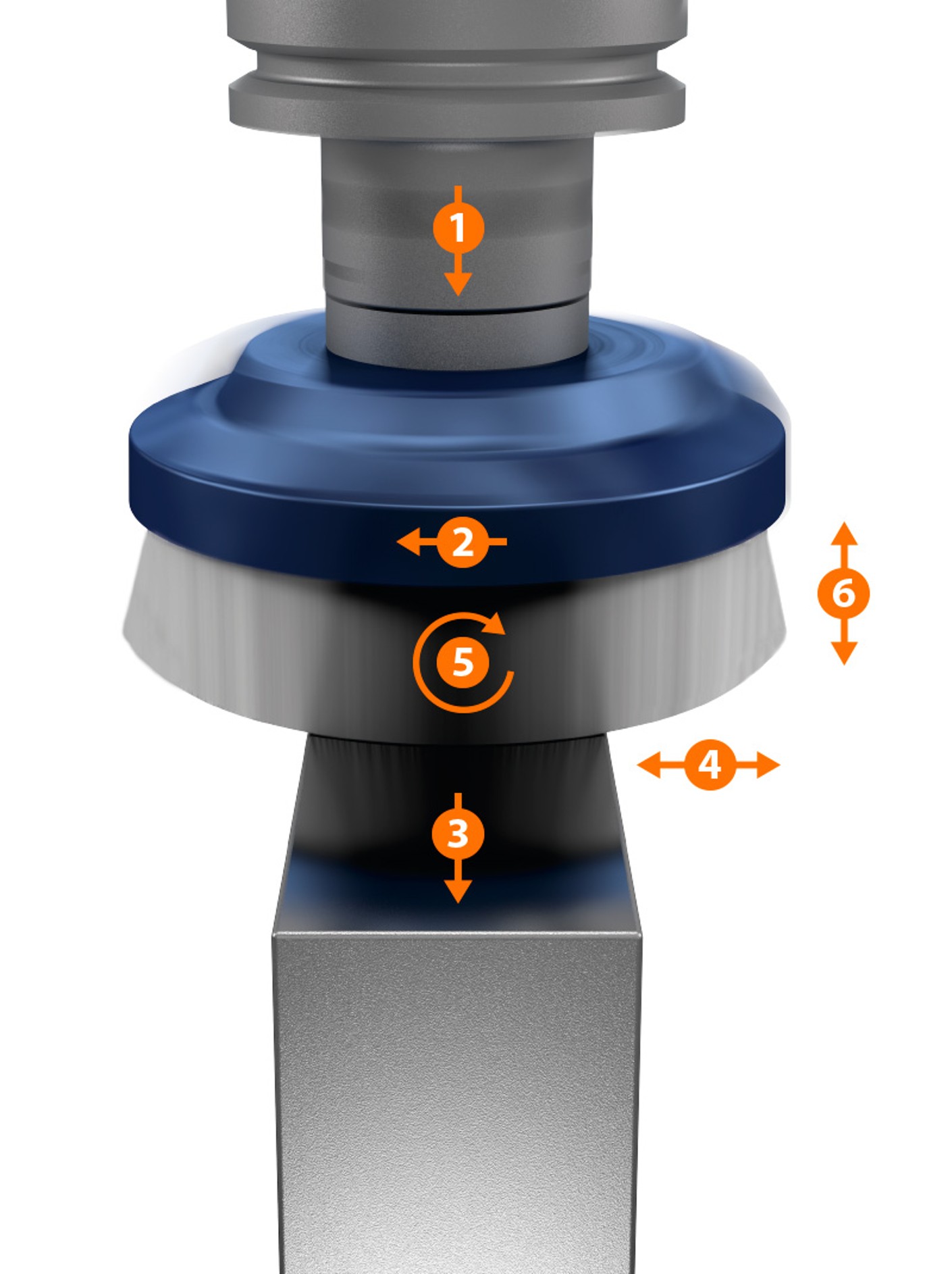

1. Infeed: The infeed for a disc brush with bristles right to the edge ideally lies between 0.8 mm and 1.5 mm. Higher values do not automatically increase the rate of metal removal, and lead to faster wear of the brush.

2. Speed: Brushes with nylon bristles work best when the speed allows the greatest number of bristles to contact the workpiece. Higher speeds do not necessarily lead to a better result. Depending on the brush diameter, the recommended speed lies between 1,000 rpm and 2,300 rpm, which is significantly below the maximum speed.

3. Feed rate: The feed rate determines the cycle time and must be optimised individually. Initially, chose a lower feed rate. If the burr is successfully removed the feed rate can be increased slowly up to the point where the burr is only just removed.

4. Overlap: The ideal overhang beyond the workpiece is approx. 35 mm on each side.

5. Direction of rotation: The direction of rotation selected should be the opposite of the direction of rotation of the cutting tool. This increases the brushing effect of the individual bristles, and removes the burr most effectively.

6. Wear limit: The wear limit of a disc brush is reached when the remaining length of the bristles is no longer sufficient to ensure the flexibility of the bristles. The bristles then no longer wrap themselves around the edge.

Travel: The travel of the brush should be selected so that on approach and retraction the full circumference of the brush projects beyond the workpiece. Only by this means can all edges be processed.

GARANT disc brushes in the eShop

Garant disc brushes are versatile and precise

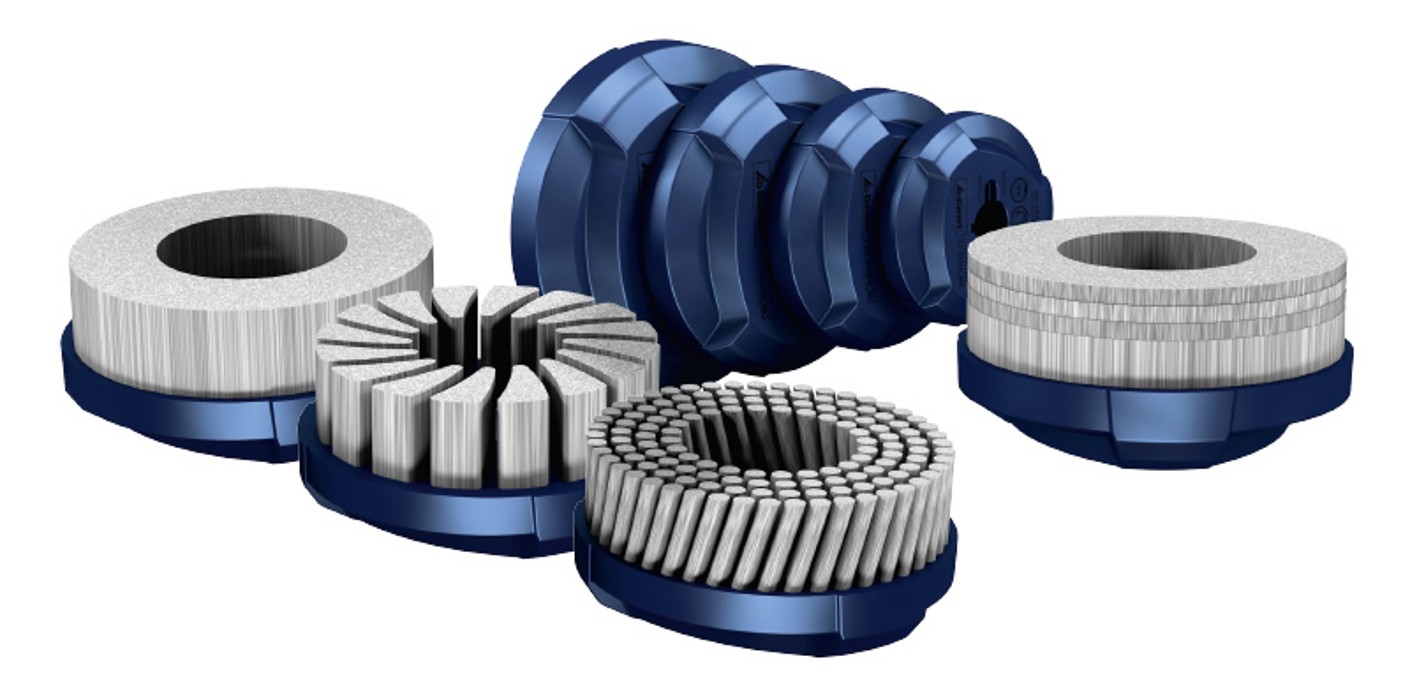

Standard mounting:

- Can be combined with all indexable face mill mountings and combination face mill adapters.

- No further accessories required.

- Positive force transmission.

Dynamic pad form:

- High concentricity.

- Maximum resistance to tipping.

- Recesses for reduced weight.

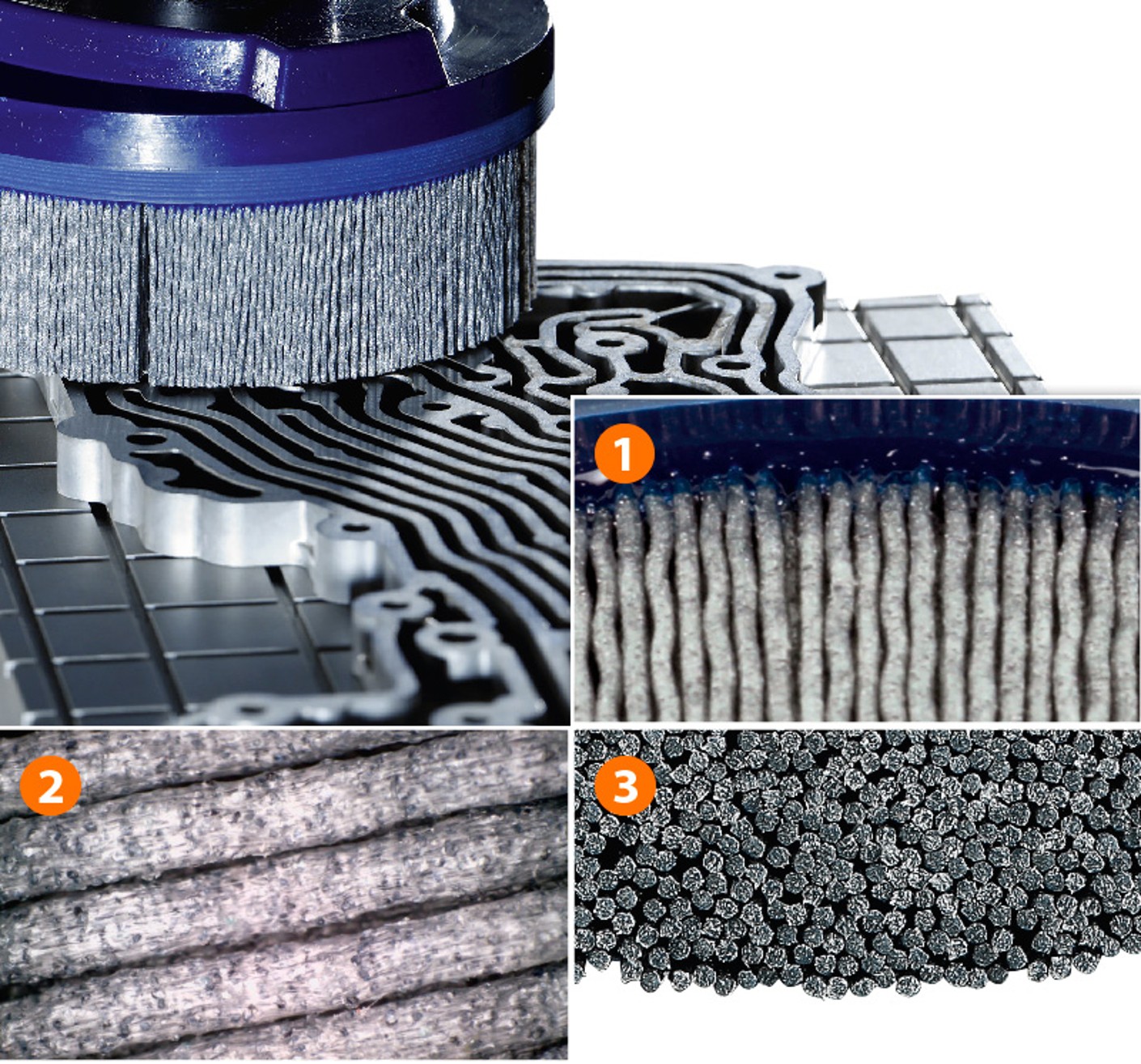

Bristles solidly cast in place (1):

- Bristles will not break off. High speeds.

- Special versions with individual densities of abrasive grit available.

High-tech bristles (2):

- Nylon bristles impregnated with abrasive grit.

- Temperature-resistant up to 160°C.

- Chemical resistance permits use of coolants (recommended).

Maximum density of the set of bristles (3):

- Aggressive brushing effect and extremely long brush life.

- Stable profile, flat surface.

- Wear behaviour controllable.

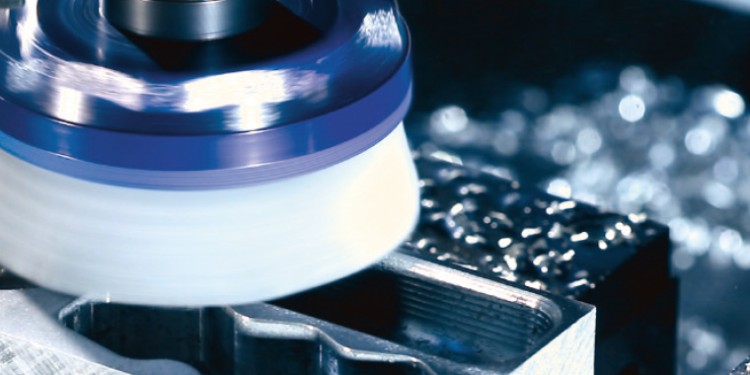

Precise edge rounding without changing the shape of the workpiece.

Finish machining of complex components.

Cleaning and finishing large areas.

Customer-specific disc brushes

Based on the GARANT base pad we configure the ideal brush for you, with bristles individually arranged for the sepcific application.

Base pad shape and diameter: Our GARANT base pad is available in four different diameters. Each base pad has a bore, transverse slot and longitudinal slot for direct mounting on combination face mill adaptors or milling head arbors.

Bristle length: Increased bristle length increases the brush life and provides increased flexibility of the brush.

Brush section shape: The aggressiveness and flexibility of the disc brush can be modified by selecting different brush section shapes.

GARANT disc-brushes have a positive impact on production costs

Reduced cycle time

After the machining process the workpiece can be finishmachined without having to be taken out of the machining centre. This significantly reduces the processing time, and the costly set-up and transport times are eliminated completely.

Consistent quality

Continuous exposure of the abrasive grit and high stability of the shape of the brushes guarantee high process reliability. The reject rate can thus be reduced and the inspection times brought down to a minimum.

Longer service life

Compared to conventional grinding tools, the GARANT disc brushes have a significantly longer service life due to the maximum density of the set of bristles.

Effective use of personnel

The automation of routine post-processing operations enables companies to make more effective use of their staff's time as they can concentrate on more specialised tasks.

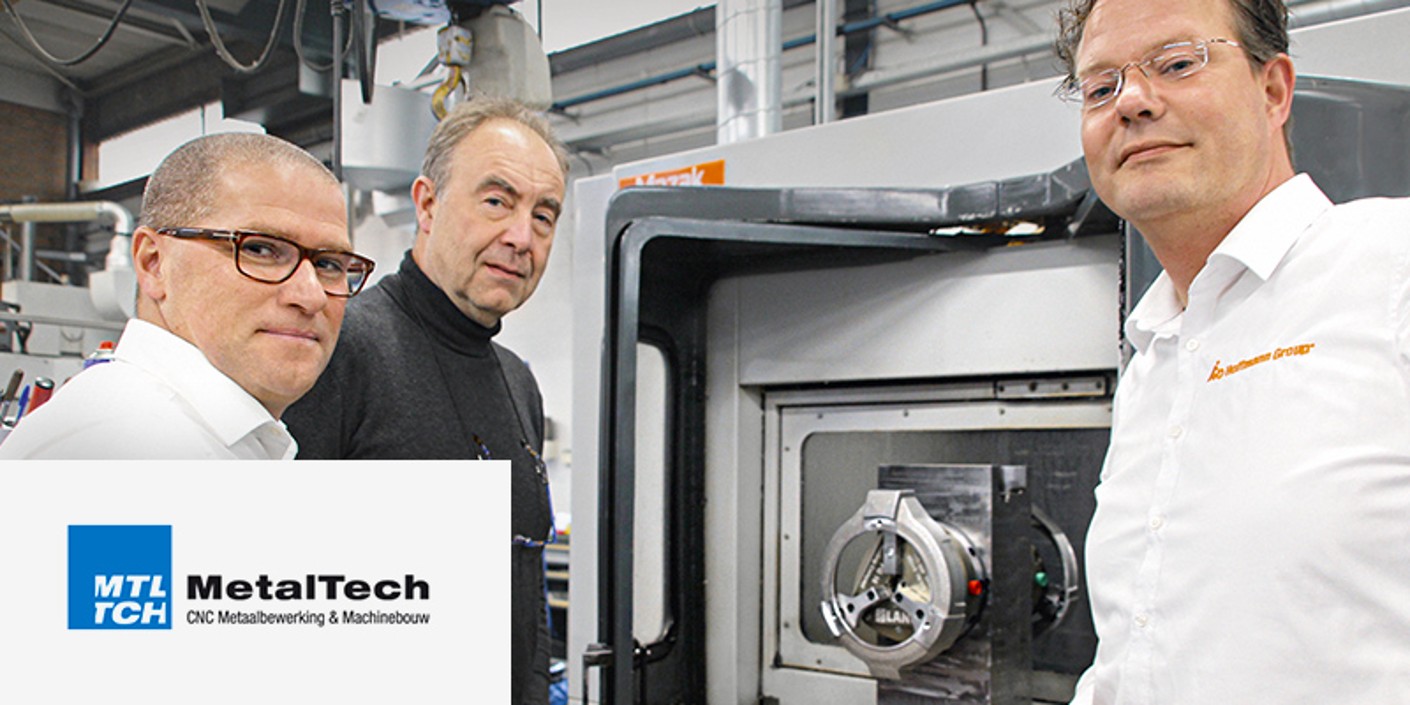

MetalTech saves 80% of process time by using GARANT disc brushes

"The brushes make the razor-sharp edges very smooth. They are perfect for deburring and do not change the dimensions of the components."

Peter van Leeuwen, Director MetalTech

At Aluro CNC, the GARANT disc brushes deliver best quality at reduced cycle times

“The GARANT disc brushes guarantee a constant finishing quality and at the same time we save several hours of work.“

Pascal Van De Sande, Technical Manager at Aluro CNC

Garant disc brushes offer numerous advantages

GARANT disc brushes with bristles right to the edge provide new possibilities for efficient deburring and surface finishing on CNC machines and in robot cells. The GARANT disc brushes are particularly suitable for use when workpieces must be finished quickly and reliably by an automated and reproducible process after the machining process has been completed.

Quick and safe fitting without the need for additional accessories as well as a very low radial run-out are just some of their many advantages.

Watch the video to see the advantages and features of GARANT disc brushes for yourself.