Version:

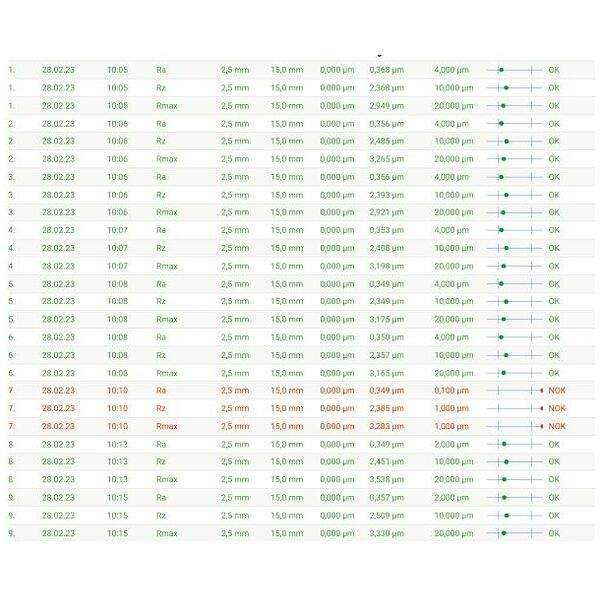

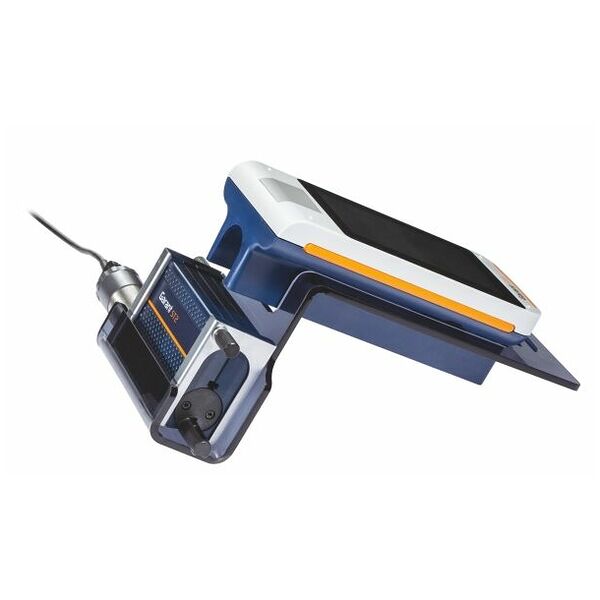

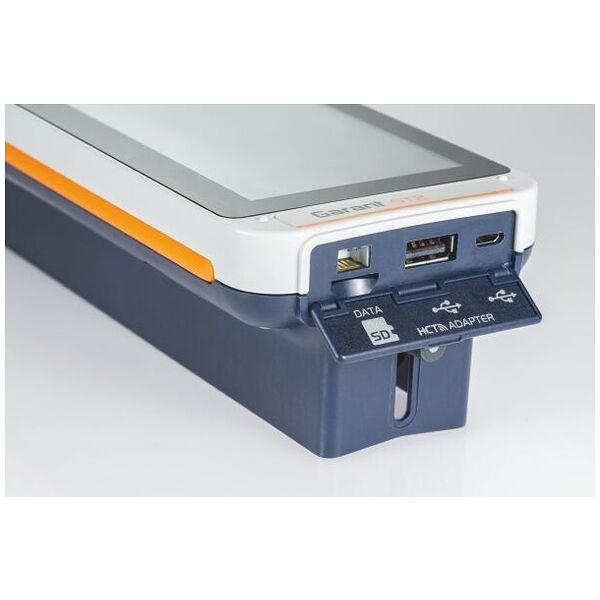

Portable roughness measuring instrument for precise roughness measurement and documentation conforming to standards, using the stylus tracing method. With integral (removable) calibration standard. Large illuminated 4.3 inch TFT touch display. Display can be rotated. Feed unit can be operated as part of the main unit and separately. LED light bar for status display (green - battery status display, red - error message, blue - measurement, data transmission), integral height adjustment, data saving as TXT, X3P, CSV and PDF files. Gauss filter to ISO 16610 − 21 (supersedes DIN EN ISO 11562), special filter to DIN EN ISO 13565 − 1, IS filter to DIN EN ISO 3274 (can be switched off). Tolerance monitoring: It can be quickly determined whether the measured value is within the specified tolerance from the colour of the parameters (green – inside and red – outside the tolerance). IATF 16949 compliant – reliable traceability.

Advantage:

- Switch on and start measuring immediately – intuitively without training, e.g. automatic cutoff selection, information on roughness characteristics directly on the device, pre-set measuring programs and quick access to desired functions by saving favourites in the display.

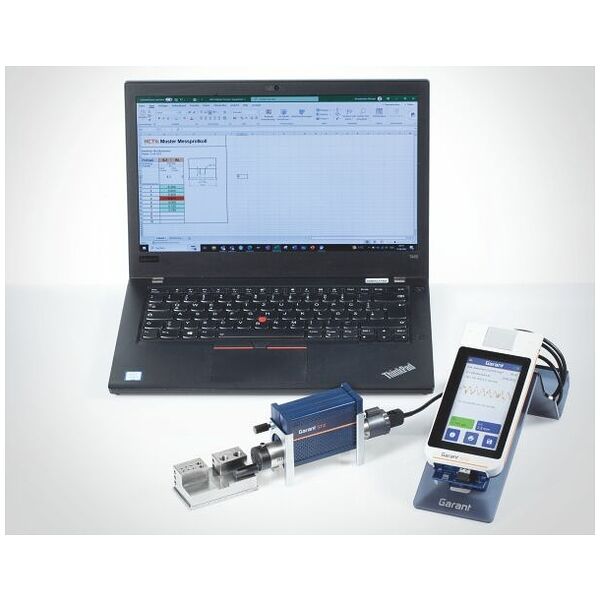

- Transmission of the measuring results wirelessly or alternatively by a cable connection. Compatible with the optional HCT (Hoffmann Group Connected Tools) mobile app. Available free of charge for Android and iOS. Can also be used via a Human Interface Device (HID).

- Summarise multiple measurements (for example, for a series) in a PDF log using the HCT mobile app. Adding a photo (for example, component or measurement setup and making individual comments on the log possible.)

- Document the results via wireless or cable connection using the optional thermal printer for printouts of the profile and results.

- The software interface of the device can be switched between bright and dark views depending on the lighting conditions.

- Ergonomic stand ensures optimum viewing angle.

- Take measurements according to the standards DIN EN ISO 4287/4288 and DIN EN ISO 21920-2:2021.

Supplied with:

Supplied with feed unit, manual Vee, erector No.

499023, standard probe No.

499004 size 6 – 350, integral roughness standard No.

499575 incl. factory calibration certificate, integral height adjustment, probe guard, charger / mains adapter, operating instructions, mini-USB cable, USB Wireless dongle No.

499024, extension cable for feed unit, carrying case.

Optional extras:

Spare part:

Warning:

Intended use- For both industrial and private use.

- Use it only in accordance with the technical data.

- Use only when it is technically in good condition and safe to operate.

- Protected against solid foreign bodies with a diameter ≥ 1.0 mm to IP 40.

Reasonably foreseeable misuse- Do not make any unauthorised modifications.

- Only open the housing on the battery cover for battery replacement.

- Do not expose the work lamp to intense heat, direct sunlight or naked flames.

- Do not use in explosion hazard areas.

- Avoid vibration, reverse movement, shaking, impacts.