Connected Manufacturing - the software for your tool management

When it comes to machining, transparent tool management, more efficient production processes and more productive employees are key to retaining your competitive edge

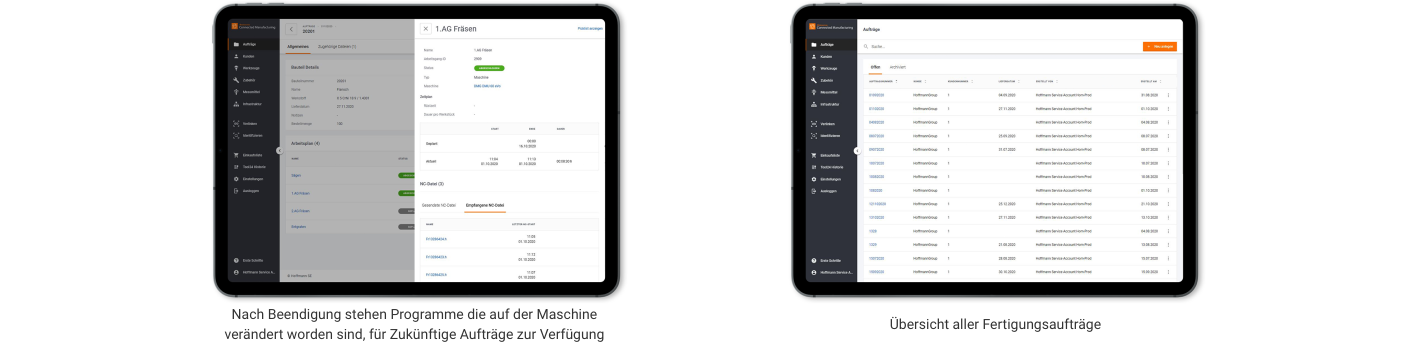

Connected Manufacturing makes your production transparent and lets you see in real time exactly what is happening in your processes.

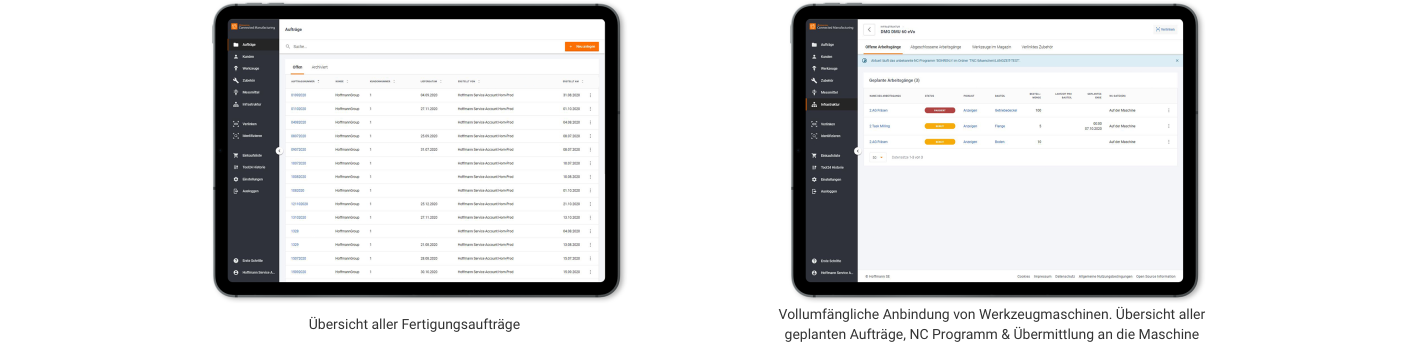

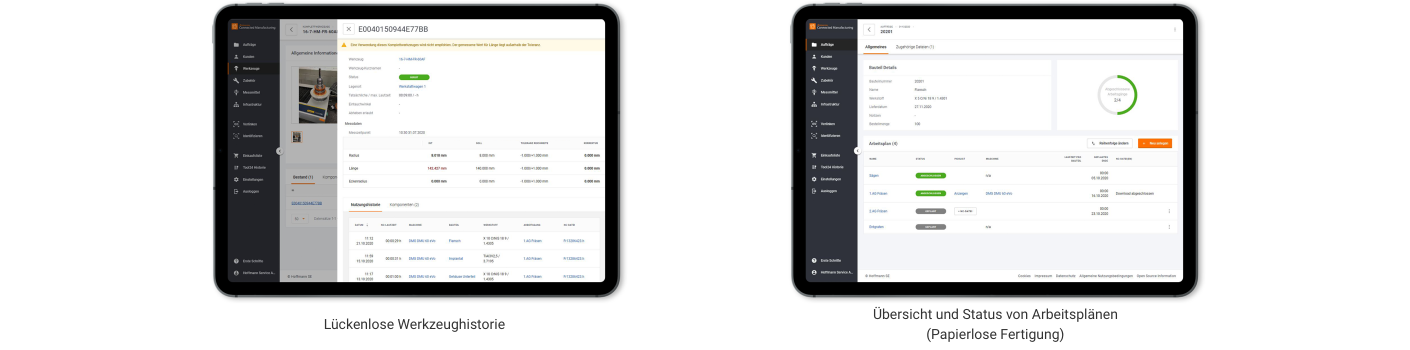

Connected Manufacturing gives you a complete overview of where all your tools and machines are along with their status – meaning you can set up and document your jobs on your machines reliably and efficiently.

CAM programming

Keep an eye on production from the comfort of your office.

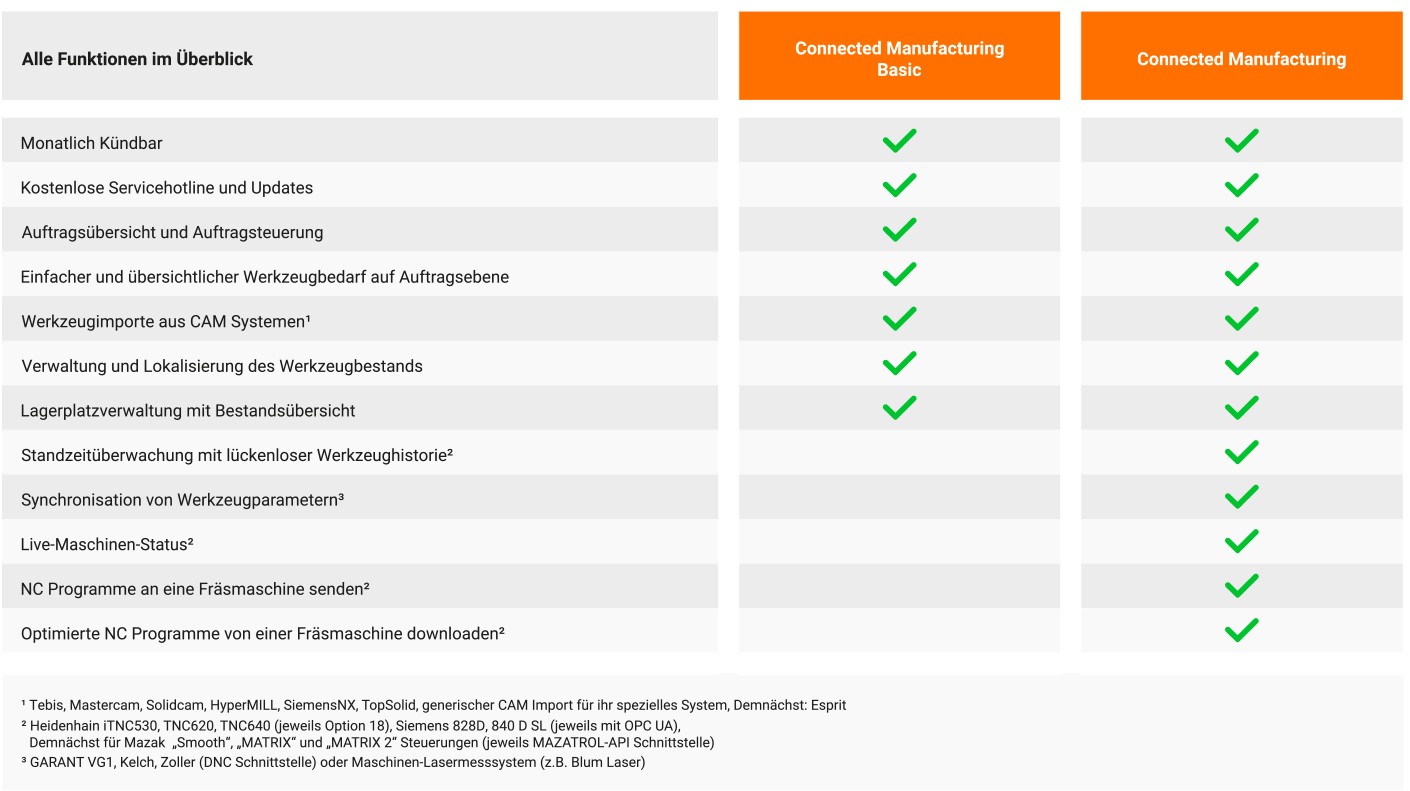

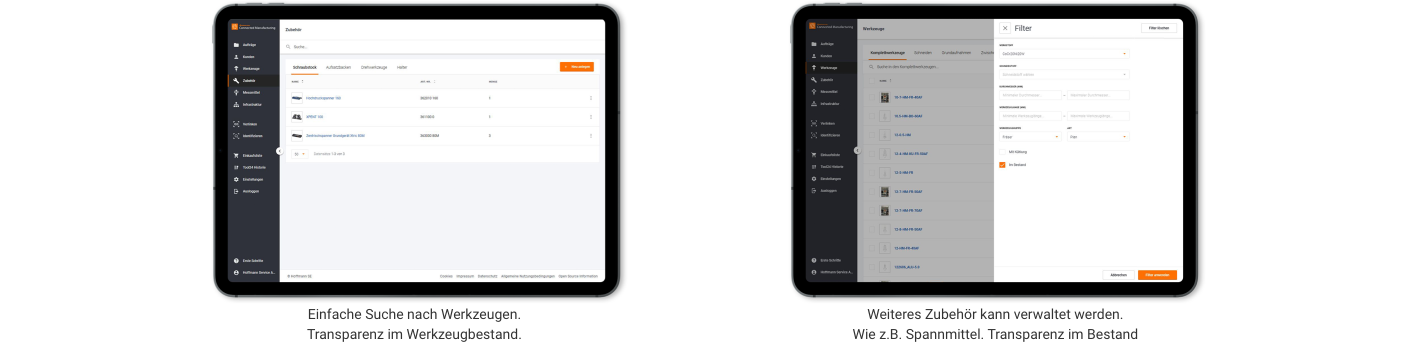

- Maintain an overview of your tool stocks (individual and complete tools) and their status and location, and re-order tools at an early stage

- Consistent tool logic and overarching tool tables for the use of tools on all machines

- Provide programs and drawings for machines directly and gain access to optimised NC programs without any special effort

Hoffmann Group Connected Manufacturing in a practical test

Company “Karlheinz Hahn – Konstruktion & Entwicklung“ is one of the first pilot customers for Hoffmann Group Connected Manufacturing, which they have been using for several months now. In a short interview Managing Director Karlheinz Hahn talks about his experiences with the new system. Find out more

Digitalise your production process with Connected Manufacturing!

Borries Schüler and Andreas Kastner show you how you can efficiently manage your tools digitally. Using the software Connected Manufacturing enables you to see what is happening in production in real time, which jobs are on the machine and which tools have to be set up. You can digitally retrieve tool and measurement data at any time > Maintain an overview and get started!

Test the introductory package for a month - free of charge!

A solution for any challenge

Like what we’re saying?

We’d be pleased to help you.

Simply contact your personal consultant at your local branch. We look forward to your call or e-mail!

Perfectly networked for maximum savings potential

Thanks to the ease with which they can be integrated into the Hoffmann Group’s “Connected Manufacturing” solution, these products are the ideal addition to automate your production.

To the CM package

To the CM package