Connected Manufacturing - the software for your tool management

Getting started with Industry 4.0 has never been so easy. The innovative software is the simple solution for digitalisation of your production and supports you in mastering the daily challenges in your production process.

Keep an overview and start

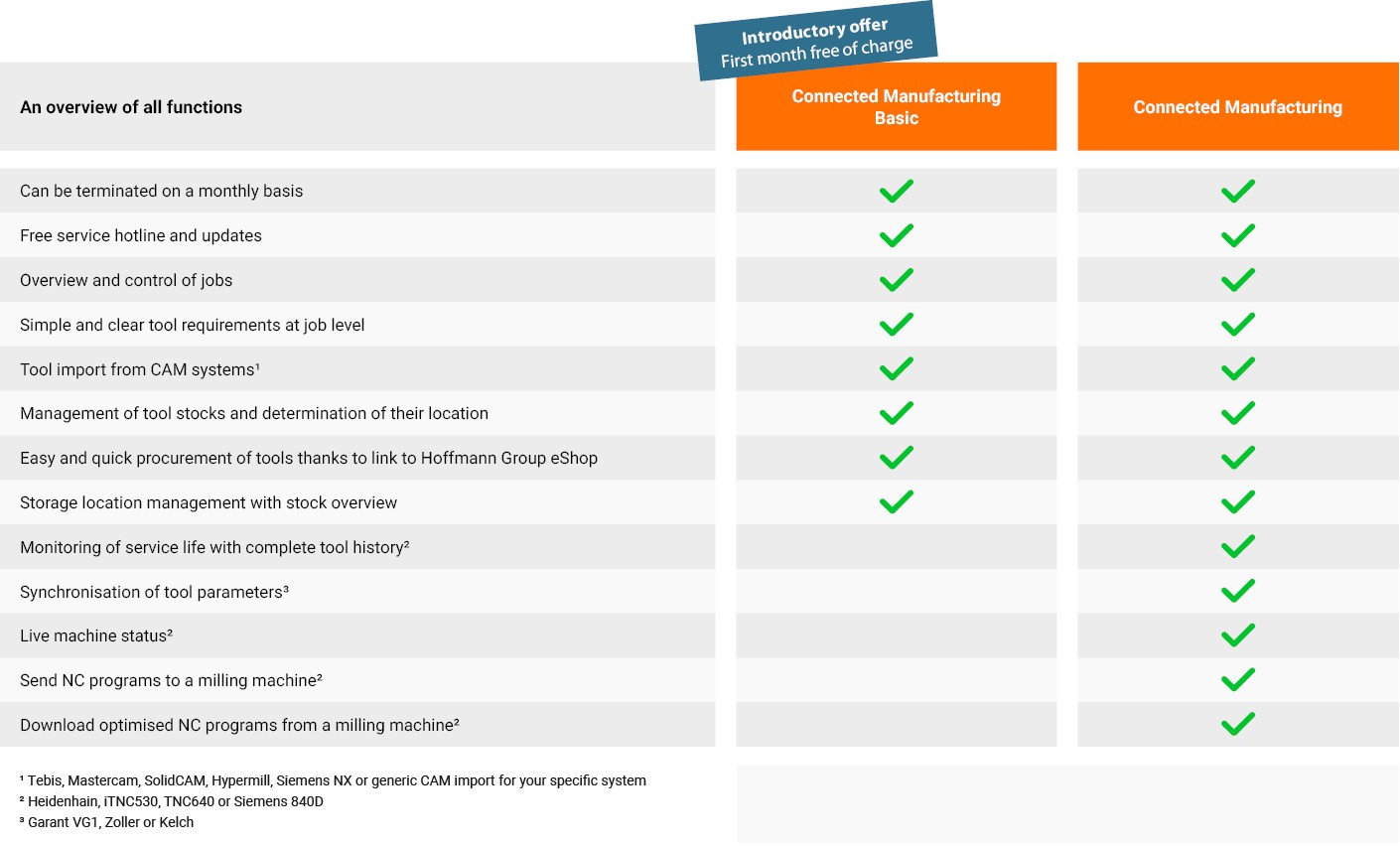

Find the Connected Manufacturing package that is right for you

You can get started directly with no large investments or effort. Our subscription model has no hidden costs and can be ordered and adjusted at any time. Commissioning in your company takes place within a few days, and thanks to our user-friendly software you will be immediately ready for use after a short training session.

Your potential for optimisation in work preparation, production, tool preparation & CAM programming

Find out here how you can save time and money at every step of production – from work preparation to CAM programming and tool preparation right up to production – with Hoffmann Group Connected Manufacturing, and thus significantly increase your productivity. This enables your employees to concentrate on what is essential and focus fully on the value-adding process. Find out more here

Hoffmann Group Connected Manufacturing in a practical test

Company “Karlheinz Hahn – Konstruktion & Entwicklung“ is one of the first pilot customers for Hoffmann Group Connected Manufacturing, which they have been using for several months now. In a short interview Managing Director Karlheinz Hahn talks about his experiences with the new system. Find out more

Digitalise your production process with Connected Manufacturing!

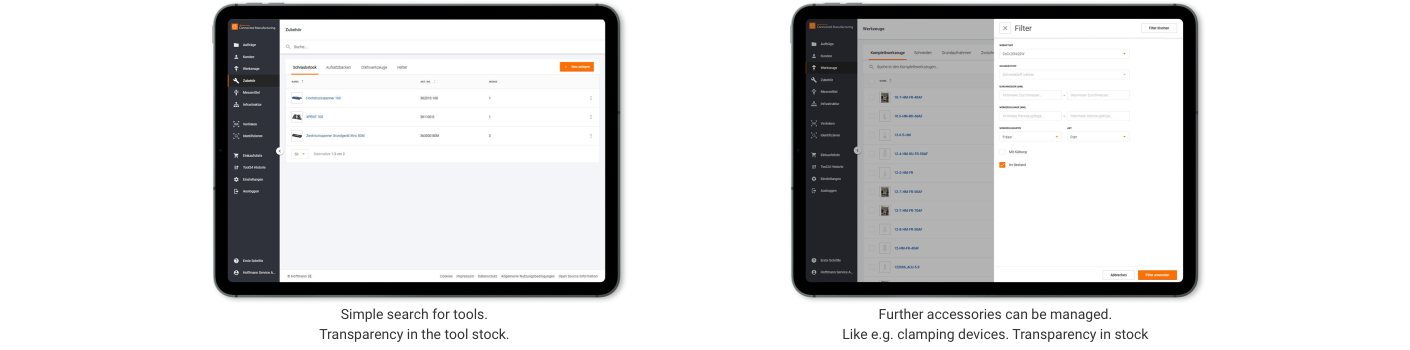

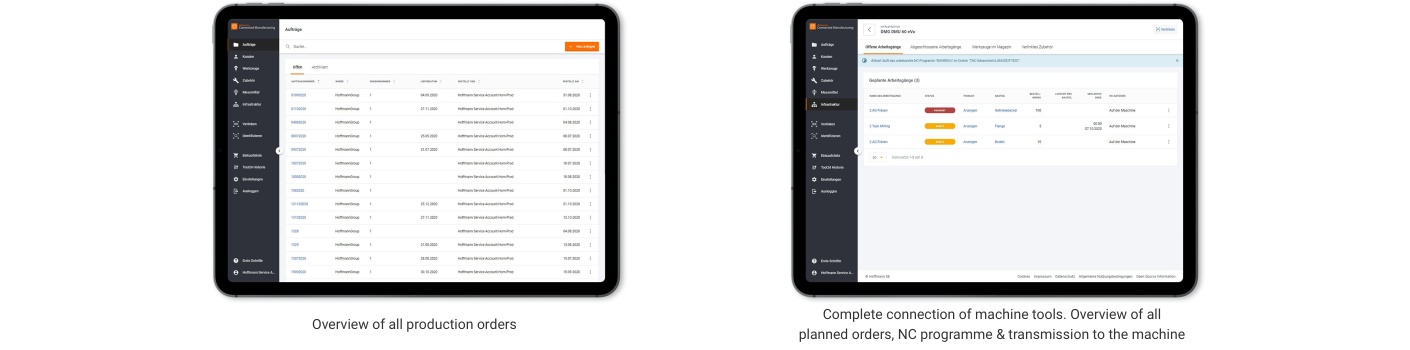

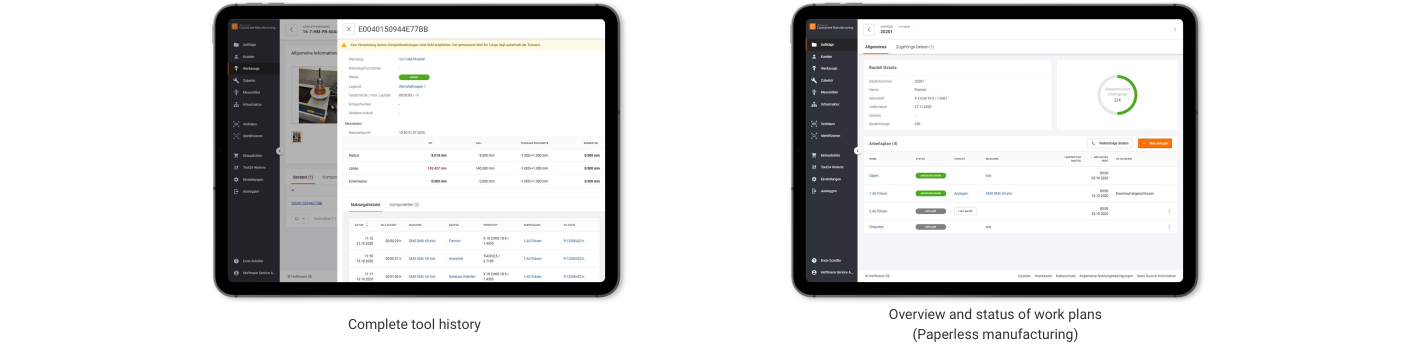

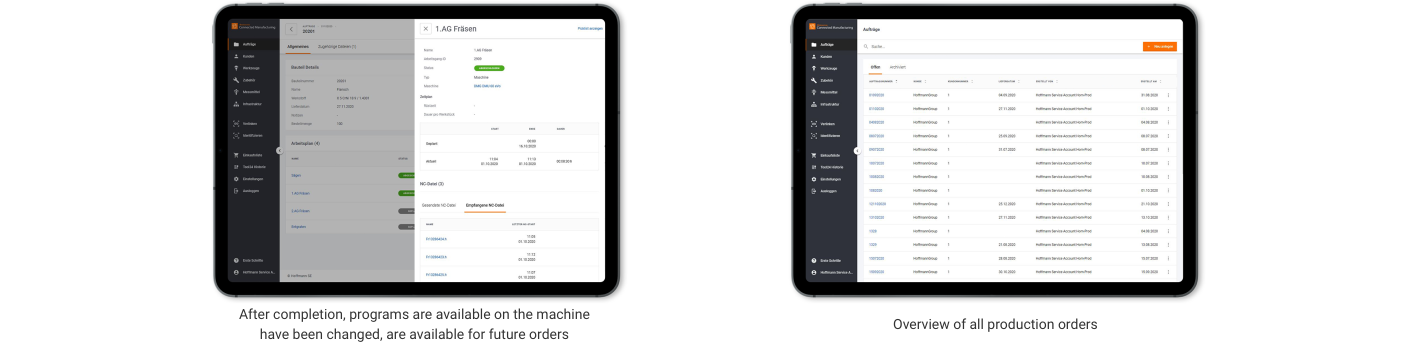

Borries Schüler and Andreas Kastner show you how you can efficiently manage your tools digitally. Using the software Connected Manufacturing enables you to see what is happening in production in real time, which jobs are on the machine and which tools have to be set up. You can digitally retrieve tool and measurement data at any time > Maintain an overview and get started!

Test the introductory package for a month - free of charge!

The right solution for every challenge

Have we caught your interest?

Then you can arrange an appointment today.

We offer individual advice on the topic of Connected Manufacturing, working with you to find a solution that is right for your application.

connectedmanufacturing@hoffmann-group.com

Perfectly networked for maximum savings potential

Due to easy integration into Hoffmann Group “Connected Manufacturing” these products are an ideal addition to the automation of your production.