Fall protection: Vital protection against deadly hazards

At least one person a day in Europe has a work accident involving a deadly fall – usually from a height of two to three metres. This makes falls one of the most common causes of accidental death in the work place; in most countries they can even account for 50 percent of all fatal accidents at work.

With fall protection as part of personal protective equipment (PPE), you can protect your employees from numerous hazards. These include:

- Insufficient training of users and individuals carrying out work at heights

- Risk of slipping due to wet surfaces and steep inclines

- Risk of tripping on uneven surfaces

- Internal injuries due to arrest shock being too strong

There are numerous application areas for fall protection: when working in high-bay warehouses, on lifting platforms, on façades or roofs, on scaffolding and steel structures, as well as rescue and specialist forces.

Different fall protection systems

Protect your employees with fall prevention. One version is a restraint system which keeps wearers away from areas in which there is a risk of falling, thereby preventing falls. Another version is described as a capture system and catches a person as they are falling.

Both systems consist of multiple parts. They include at least a body arrester device, for example a safety harness, and a connection to a fixed or mobile anchor point.

A third version is permanent fall protection, for example in the form of safety railings.

Individual parts and their functions

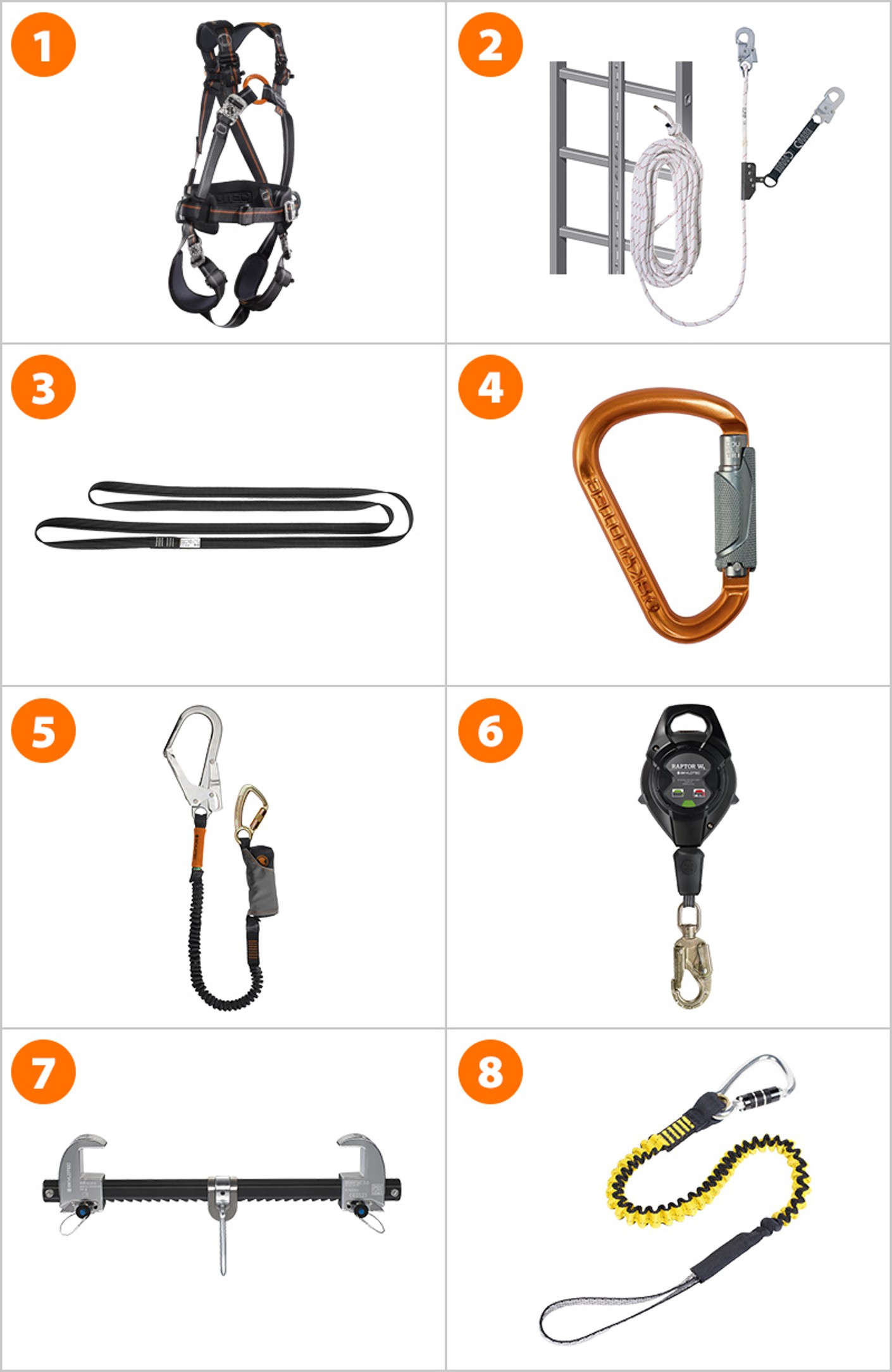

The individual components of fall protection equipment have different tasks. The safety harnesses (1) consist of waist belts which fasten around the body. These catch the person as they fall, transmit the resulting forces on to appropriate parts of the body and keep the body upright.

The attachment devices (2) come in two basic designs: with a fixed or a moveable guide. On the fixed guide, the attachment device that moves with the user automatically locks and catches the user with the safety harness. The fixed guide restricts lateral movement. The attachment device with a moveable guide moves up and down the guide as the wearer moves. If the wearer falls, it locks automatically.

Cables or waist belts with end connections are connectors (3). Connecting elements (4) connect the individual parts with a capture system. Fall dampers (5) reduce impact forces acting on the person, the safety harness and the stop device in the event of a fall.

Height safety devices (6) automatically engages if a person falls, stopping the fall. They permit free movement within the cable extension range.

Stop devices (7) are made of different parts with one or more attachment points. These create a fixed connection between the system and the building or structure.

Fall prevention safety harness sets include all parts which are required for basic equipment. These allow your employees to work safely on lifting platforms or roofs, for example. Additionally, the tools which your employees working at height are using should be prevented from falling so that people at ground level are not injured by falling objects. Special tool fall protection (8) is available for this.

Do you have any questions? Our experts are keen to help you at any time:

What to take into consideration when selecting products?

When selecting the appropriate personal protective equipment against falls (PPEaF), application area, fall height and wearing comfort play decisive roles.

The right system for each application area

In order for personal fall protection to function smoothly, the individual components of the restraint or capture system must be perfectly coordinated to one another. Additionally, they can only be used in the manner which was intended for them, as each individual component fulfils specific requirements which are defined by the corresponding standards. Manufacturers provide information for their products regarding which conditions the respective systems can be used in. In this regard, the following factors play a role:

- Application area

- Height and weight of the wearer

- Duration for which the fall protection is worn (occasionally or continuously)

- Ambient conditions (e.g. extreme heat)

Catching people safely in the event of a fall

The goal of PPE is always to limit the fall distance. Without a fall damper, even a fall of 0.5 m creates a force on the person equivalent to dropping a 1.2 t weight on them. With a fall damper, the force is equivalent to a maximum of up to 600 kg. This weight determines the force of the arrest shock, which can cause serious injuries to the wearer. The fall factor corresponds to the relationship between the fall length and the system length. The force of the arrest shock increases with the fall factor. In the ideal case, the fall factor should be ≤ 1. To keep this factor as low as possible, optimal positioning of the attachment point is also important. Doing so will reliably catch a potential fall.

Optimal wearing comfort

If your employees have to wear fall protection in their work on a consistent basis, wearing comfort is crucial. In this regard, back padding on the belts as well as elastic and adjustable waist belts ensure that the equipment is comfortable to wear.

Checking and maintenance of fall protection

Employees have the responsibility to check the personal protective equipment against falls for defects before every use and also replace it if necessary. If the product is damaged, it must be inspected by a certified person or specialist dealer. Companies should use and store fall prevention equipment in such a way that its correct functioning is always ensured. Additionally, the fall protection equipment must be inspected annually by a qualified expert who documents the results in an inspection logbook. Straps should be replaced every six to eight years, and connections should be replaced every four to six years, assuming these do not exhibit defects within this time. Items from the 2019 production year have a service life of ten years, provided that they are inspected annually.

High-quality fall prevention and expert PPE advice

The Hoffmann Group’s product range includes all fall protection components as part of personal protective equipment. We offer you selected products from well-known manufacturers known for their high quality, functionality and reliability.

If you have questions about the topic of fall protection, our expert team of PPE specialists will advise you personally and together with the manufacturer – because the correct usage could be the difference between life and death! We will be glad to provide you training courses on the correct use of personal protective equipment to prevent falls. These include modules of training and instruction. They can be fully adapted to your individual needs. Training can also be provided in one of our twelve training centres in Europe. Above a certain number of people, we can even offer on-site training sessions.

Specific standards for fall protection

Before selecting and using personal protective equipment against falls, the employer must perform a hazard analysis. The hazard analysis determines which hazards cannot be eliminated or reduced by technical or organisational measures. In general, collective protection (e.g. safety railings) always has priority compared to mobile stop devices or a protection system. The personal protective equipment used for fall protection must satisfy the applicable regulations for protection of health and safety:

- EN 353-1: Guided type fall arresters including a rigid anchor line

- EN 353-2: Guided type fall arresters including a flexible anchor line

- EN 354/362: Lanyards/Connectors

- EN 355: Energy absorbers

- EN 360: Retractable type fall arresters

- EN 361: Full body harnesses

- EN 795: Anchor devices

Frequently asked questions about fall protection

Is it permissible to combine multiple type-tested part products from different manufacturers to create a complete product?

This is permissible so long as the individual part products combine to create one capture system. When it comes to combination possibilities, the inspection criteria for inspecting the individual system parts are to be taken into consideration.

The combination of individual elements/part products which are not inspected in said combination is not permissible. For example, an attachment device that moves with the wearer produced by manufacturer A cannot be combined with fixed or moving guides from another manufacturer, as in the framework of the EC type approval, attachment devices which move with the wearer are always inspected with their corresponding guides (DIN EN 353-1, DIN EN 353-2).

Are the instructions for use for the descender devices necessary?

The instructions for use provided by the manufacture/supplier must be present for each descender device in order to facilitate access to all required information which is necessary for safe use.

Adherence with the information in the instructions for use ensures safe working conditions and the long service life of the descender device.

Do you have any questions? Would you like to receive advice on PPE?

The Hoffmann Group provides you with everything from a single source:

- We provide individual advice, tailored to your needs

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Personal protective equipment also includes: eye protection, breathing protection, hearing protection, foot protection, hand protection, head protection, protective work wear, work clothing and skin protection. This takes you to the overview.

To advice for fall prevention

To advice for fall prevention