The lighter side – working with aluminium

When you're managing production in aerospace engineering, the automotive industry or along supply chains, especially if you're realising lightweight designs, aluminium takes a load off your hands in more ways than one. As a metal, it has a low specific weight but is still very strong. And aluminium possesses additional beneficial properties – it's resistant to corrosion, has good electrical conductivity and is easy to machine. Compared with other metals, aluminium is also ahead when it comes to recycling. An aspect you shouldn’t take lightly if you're looking out for economic viability and sustainability. Read on to find out how you can use aluminium to produce visually pleasing components and why aluminium is a coveted material for lightweight design. You’ll also learn some nifty tricks for machining aluminium and for getting the best results when grinding and cutting it.

The stuff of dreams for the aesthetically minded

Aluminium is popular not only for its specific properties, but also because its silver sheen makes the metal look great. Besides being used for interior decoration, aluminium – in pure form or as part of new alloys – also really shines in the architecture and building sectors, where it’s a popular choice for anything you want to be both functional and beautiful, like facade cladding for example.

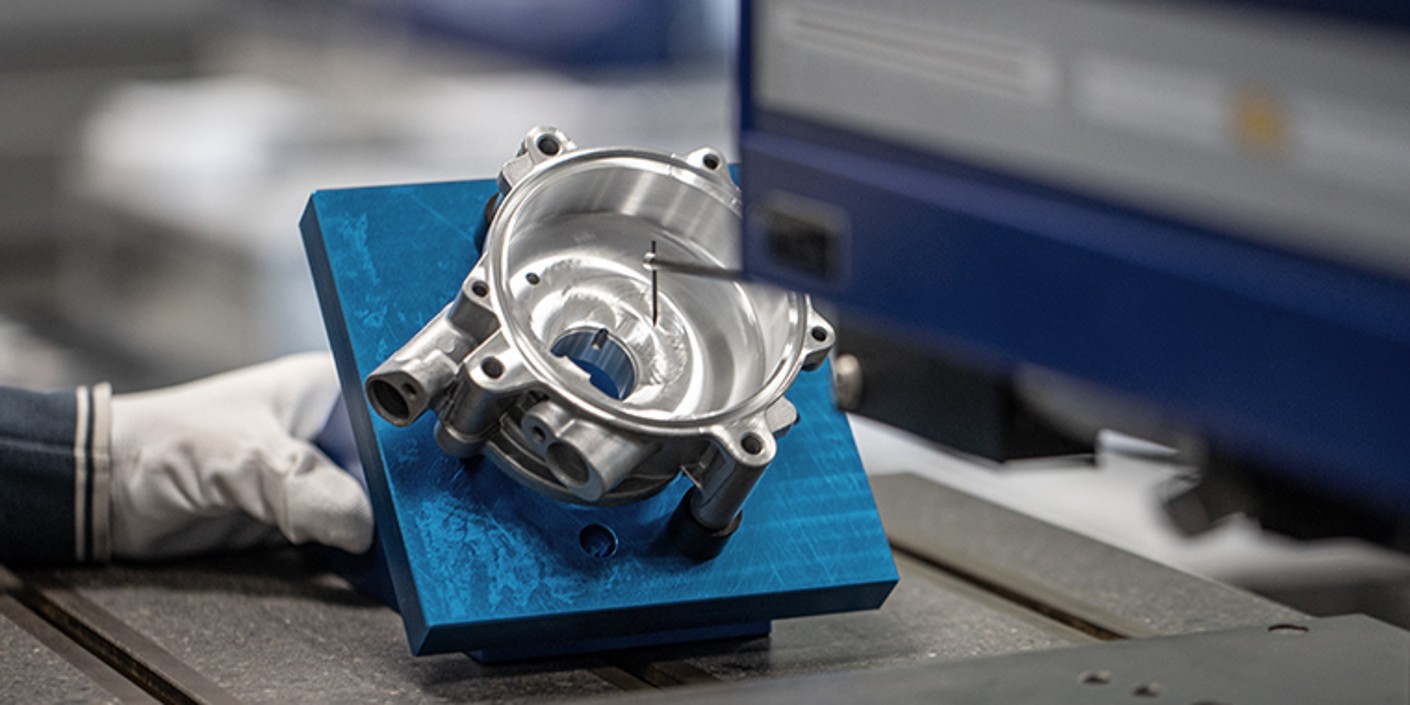

Lightweight, strong and aesthetically pleasing – a must-have in many sectors

In pure form or alloyed: aluminium is also an excellent material for mechanical and plant engineering. It's used anywhere that low weight means a gain in dynamics and efficiency. This might be large-scale body panels for all kinds of vehicles, but could also be fittings in a car’s interior, engine blocks or cylinder heads. In short: almost every sector benefits from aluminium's low weight and use it to achieve the best-possible efficiency, for example by manufacturing machinery components from it. One of the best examples is one production managers like yourself probably see all over in your day-to-day work – the excellent and reliable combination of light weight and strength in robot components or linear actuators. Properties that are also in high demand in shipyards and train construction.

If you’re a master craftsman in the construction industry, you’ll love aluminium's beneficial properties just as much. Property developers and architects alike use it for a multitude of things, from window and door frames to facade cladding to roof and wall systems all the way down to sturdy fittings, handles and grilles. Aluminium is also great at working ‘behind the scenes’, e.g. as mouldable thin heat insulation. Speaking of thin: aluminium is almost completely indispensable as a packaging material, protecting as it does wrapped food from exposure to surrounding conditions. Because of its electrical and thermal conductivity, aluminium is also among the top choices when it comes to manufacturing electrical cabling or coil windings for transformers and the like.

Easy on the pressure – aluminium is a softer sort

When it comes to machining, aluminium is your friend. As a material, it’s on the softer side, so you need a good deal less force and can also apply higher cutting speeds.

We recommend:

- To get the best results, make sure to keep your tools cooled and lubricated properly when cutting, turning, milling and even when drilling aluminium.

- When machining aluminium, always use tools with larger rake angles – this way, the soft swarf is carried off better.

- From a production perspective, you should also always keep the notion of ‘oxidation’ in mind: where aluminium comes into contact with air, and thus oxygen, an oxide layer forms immediately.

- You can avoid this by seal-coating surfaces immediately after machining, for example.

Easy trimmings: straight-tooth saws

The simplest way to cut aluminium is to saw it. But be sure to choose the right saw blade to do so – for cutting the soft material aluminium, metal saw blades with zero set are best suited. When using powered saw blades, it’s best to favour slower speeds. Feed rates should also be lower and match the material. This applies in equal measure to synthetic resin bonded cutting discs, abrasive flap discs and grinding discs.

Keep your eye on the grind

Because aluminium is so soft, you’ll need to watch out for a certain degree of melting smear when grinding it. How much pressure to apply when grinding depends mainly on its quality and the alloy in question. Even when using hard and brittle duraluminium, for example, you’ll need to make sure that you’re applying the right grinding pressure. Whatever the pressure, any grinding process will always compress an aluminium component’s surface. You can use this to your advantage in finish machining, for example for polishing. Its good thermal conductivity means that heat generated by grinding dissipates readily. Some helpful tips:

- Always work carefully to avoid damage to the material. We find it best to use grinding media with added abrasive coating and cooling effect, or to use grinding oils.

- Favour larger grains when starting grinding and reduce it in steps of 100 to approach the finer surface finish.

- If your component has been varnished, start with a coarse grinding disc and high speed. Proceed with care – applying lots of pressure does not automatically mean you’ll remove more material, but will quite likely leave unseemly grinding trails.

- To adjust material removal, increase speed instead. Whatever you do, make sure to take your time when choosing the right grinding tools for the job. Non-woven abrasive tools with open web surfaces are ideal, for example.

Take your time in choosing grit type, too.

- Base aluminium oxides are perfect.

- Electro-carborundum, on the other hand, react with the aluminium, something you want to avoid at all costs.

- Grinding media with ceramic grit, which have great self-sharpening properties, are a good choice, too, as is sharp silicon carbide.

- When it comes to choosing the right brush, consider using nylon bristles with SiC or stainless steel edging.

If it’s your first time working with aluminium, it may make sense to spot-test pressure and speed before you get to work on larger surfaces.

Caution: Never use tools that have been or will be used with any material other than aluminium. The tool could otherwise work other metal particles into the aluminium. This kind of machining defect leads to corrosion or damaged material and in the worst case means scrapping the workpiece.

Welding aluminium – no easy feat

Perhaps you already know from your daily work – welding aluminium is no easy task thanks to its 660°C melting point. What's more, you need to feed a much higher temperature because aluminium has such excellent thermal conductivity. Once you’ve managed to get a cleanly fused weld seam that's free of gas bubbles, seam finishing is next on the list.

- First off, you adjust the seam to merge visually with its surroundings by grinding it down to the same height as the surface around it.

- It's best to err on the side of finest grit size if you intend to further refine your workpiece’s surface.

- Use high speeds and make sure you're dissipating heat properly.

- To prevent the discs from vitrifying, your contact pressure should be high, but not too high – you’ll notice excessive pressure from the unusual tool sounds. Fibre discs are the item of choice for achieving high removal rates while still going easy on the material.

- Keep an eye on the heat and make sure cooling keeps up. Finally, polish off any remaining scoring. Now your weld seams merge seamlessly with the surface.

Rivalling chrome – polished aluminium

Once you’ve removed all the excess material from your aluminium component and given it its final shape, it's time to choose your options for final polishing. You might choose a polishing machine or an angle grinder with adjustable speed. Even a drill with a classic polishing bit can be the right tool for smaller jobs.

What’s certainly true is that the right tool always depends on how many components regularly need polishing on your production floor.

Manual or machine-driven, correct use of special polishing discs and polishing pastes will lend even the dullest aluminium a sheen you can be proud of.

Natural protection? Check!

Untreated and blank freshly pressed or rolled aluminium sheet will tarnish with an oxide layer really fast. This layer will grow depending on how long the (component) surface remains exposed and in contact with the ambient air. In some cases, this process is actually desirable. Starting off bright, then turning grey, this layer steadily turns into an optimal material protector. But as a master craftsman, you might want to buff up your components’ looks again – luckily aluminium is easy to clean up. Remove the soiling in two steps – pre-wash followed by thorough cleaning using brushes, sponges and, where necessary, abrasive paste and cleaning agents. Afterwards, wash off all the residue and apply a preservative, water-repellent cleaner.

Special case: cleaning before welding If you're planning on welding components or surfaces, it’s really important to remove every trace of grease or oil. Note that you’ll always be removing grease and oil first, before tackling the oxide layer. Oil and grease are easily taken care of using organic solvents, for example acetone or a mild cleaning lye.

Scrubbing off oxidation using a stainless steel brush will preserve the material – but make sure the brush is never used on materials other than aluminium! Alternatively, there are a number of sprays you can use to prep surfaces for welding jobs.

To the consultation

To the consultation