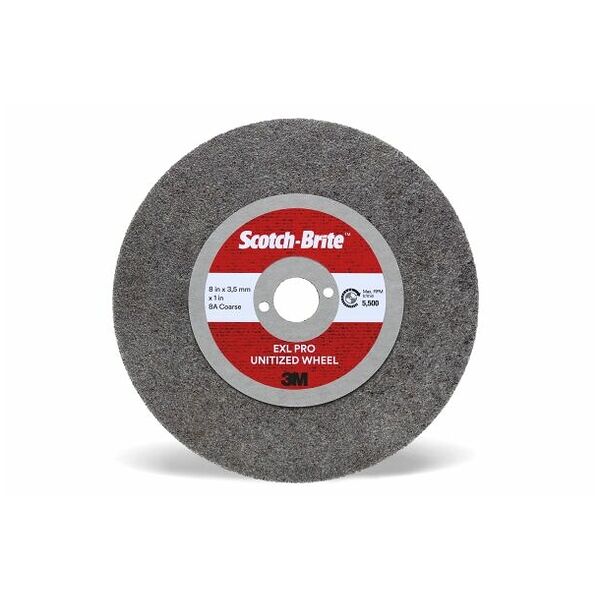

Scotch-Brite™ EXL PRO Unitized Wheel, 203.2 mm x 4.2 mm x 25.4 mm, 8A CRS

Product details

Technical Data

| Type of product | Non-woven abrasive |

Identification & Classification

| Article number | 7100133775 | |

| EAN / GTIN | 50076308132564 | |

| Manufacturer number | 7100133775 | |

| Manufacturer/responsible person | 3M DEUTSCHLAND GmbH, Carl-Schurz-Straße 1, 41453 NEUSS, Germany, www.3mdeutschland.de |

Description

Description:

The Future of Automotive Production

The Scotch-Brite™ EXL PRO Unitized Wheel is used primarily to finish seams on metal parts that have been assembled using a laser brazed joint. Laser brazing is a production process whereby parts are attached bonded to each other with a silicon bronze braze then blended to create a more uniform segment. This technique allows parts to flex and withstand the strain of driving without the need for rubber sealants. The removal and finishing of excess metal makes these brazed parts as clean and smooth as the attached surfaces, making the surface look more uniform and futuristic.

The Scotch-Brite™ Advantage

Nonwoven technology makes Scotch-Brite™ industrial abrasives unique. The combination of fiber strands, resin, and abrasive mineral in the Scotch-Brite™ EXL PRO Unitized Wheel forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products may enhance productivity while reducing the need for cleaning chemicals and wire brushes. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Advantage:

- Designed to blend and finish silicon bronze parts for laser brazing

- Open web construction resists loading and extends effective service life

- Tough, layered, unitized construction can operate clockwise or counterclockwise directions

- Resists smearing for cleaner surfaces and less preparation

- Minimizes heat build up to lessen impact on heat-sensitive materials