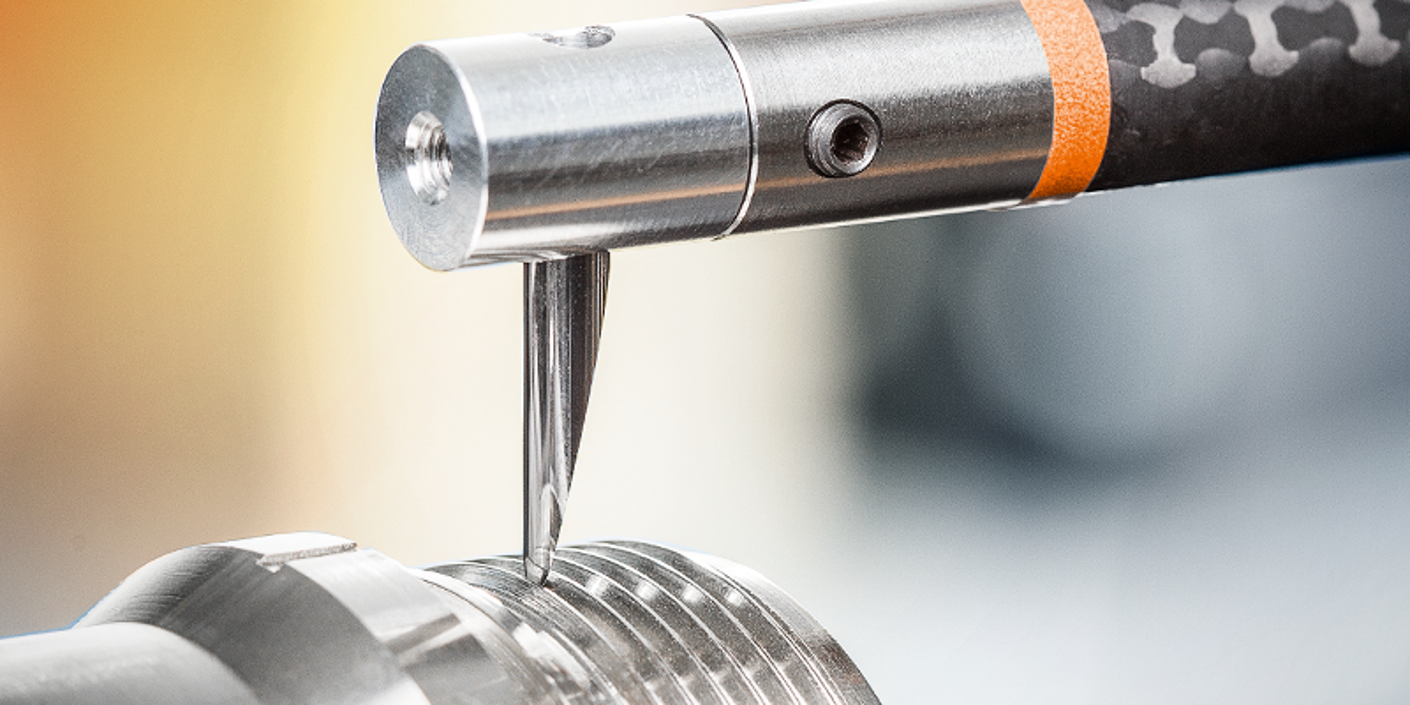

Excellent Precision thanks to Calibration provided by the Hoffmann Group Calibration Service

Welcome to the future: Our new calibration laboratory.

New address – the same good service. From the beginning of August 2021 we will perform initial calibration of our measuring tools at our modern calibration laboratory in Nuremberg, and recalibration at our partner Trescal, who have a presence in 24 countries – uncomplicated, quick and precise.

From August 2021 we will be offering maximum precision and top quality at our brand-newcalibration laboratory at our Nuremberg site. With Trescal we have brought the global leader in calibration services on board.

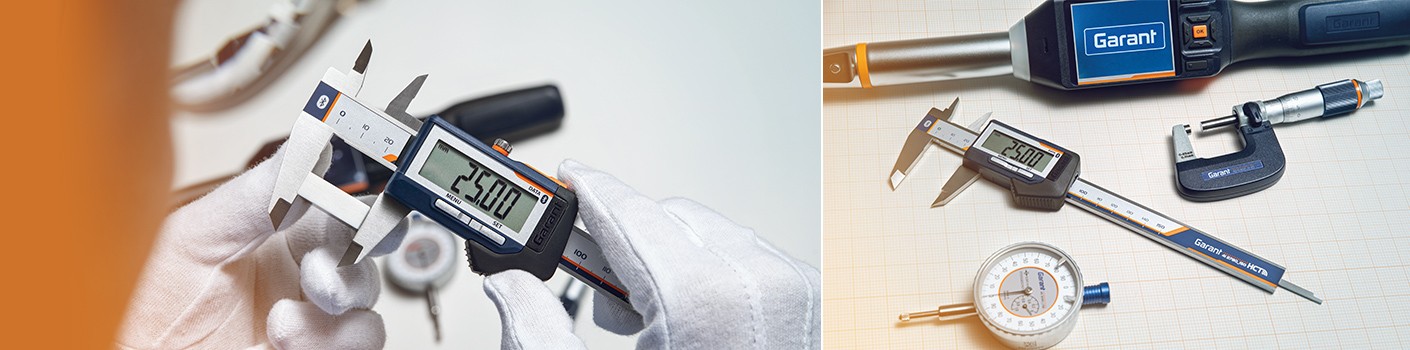

Your measuring tools in the best hands

From goods receipt, preparation and laboratories through tooutgoing goods, only specialised professionals work on your order as before. Thanks to Trescal’s wide range of accreditations, our experts calibrate a hugely diverse range of measuring tools from many different manufacturers every day. We support the measurement technology areas in your company with expert advice, thereby ensuring the quality of your products and services.

Simple handling

Simply send your measuring tools to our new address forrecalibration from 01.08.2021. You don't have to change anything for orders from our catalogue. We will take care of everything! If you have any questions, you will benefit from our comprehensive expertise and optimum consultation as usual.

Sounds simple? It is!

Which calibration interval is the right one for me?

Choosing the right calibration interval plays a key role. As a producer, you want to keep the risk of incorrect measurement as low as possible, whilst simultaneously keeping track of economic factors. The optimally selected calibration cycle can ensure the quality of the testing equipment and thus ensure themeasurement. In accordance with relevant standards, the calibration must be certified at regular intervals. Many companies start with a calibration interval of 12 months. Depending on the frequency of use, quality requirements and wear, the interval may however be reduced or extended. The company that uses the measuring tools is responsible for regular recalibration.

The following criteria can help you specify the correct calibration interval:

- Frequency of use and wear.

- Operating conditions and characteristics of the testing equipment.

- Environmental influences such as temperature.

- Quality requirements of customers and standards.

- Recommendation from the manufacturer.

- Experience with similar testing equipment.

- Consequences of consequential damage to defective testing equipment.

Use a professional service.

Our experienced employees recalibrate your measuring tools or testing equipment, and send them back to you safely packaged. You can track the current status of your testing equipment in our online portal.

You can find the current status of your testing equipment at: ho7.eu/dsp.calibration

Calibration certificates

Your calibration certificates are saved centrally and can be called up as a PDF at any time for 10 years. With us you have peace of mind – we do not pass any data to service providers. In addition to the official calibration certificate from our partner Trescal, you will receive an information sheet containing all important data.

You can find the calibration certificates at any time at:ho7.eu/dsp.calibration

Trescal - our competent local partner. Your benefit from international experience.

Our calibration laboratories are amongst the most modern in Europe. With Trescal as a strong partner we bundle together the experience and competence of both professionals and we can offer recalibration throughout Europe, the USA, Asia and North Africa.

Our new partner has an impressive international presence and more than 20 years of experience in the field of calibration.Trescal offers comprehensive expertise in the field of testing, calibration and repair and has numerous accredited laboratories worldwide. By including Trescal in our Technology Center in Nuremberg, we as the Hoffmann Group provide the combined knowledge and tried-and-tested service of both companies for you.

Here are some important facts about our new partner we have summarised for you:

- Founded in 1999.

- Headquarters in Paris.

- In-demand partner for leading companies in the chemical and pharmaceutical industry, aerospace, the automotive industry, electronics, electricity and telecommunications.

- With more than 620 accreditations worldwide in 25 measurement variables, Trescal has a unique portfolio of accreditations.

Once your measuring tool arrives at our calibration laboratory, they are first prepared for the calibration and brought to the right temperature. During the calibration, the measuring tools are checked using specialised processes and, upon request, calibrated in accordance with international standards. The outcomes and potential deviations from the test standards are evaluated and documented in a calibration certificate. After the calibration, we send the item back to you safely, together with the calibration certificate.

Calibration Procedure in our Laboratory

Save valuable time by using our pick-up and delivery service. By using our rental boxes, you can rest assured that your measuring tools will be transported quickly and reliably. Once your measuring tools arrive at our calibration laboratory, they are first prepared for the calibration and brought to the right temperature. During the calibration, the measuring tools are checked using specialised processes and, upon request, calibrated in accordance with VDI and DAkkS. The outcomes and potential deviations from the test standards are evaluated and documented in a calibration certificate. After the calibration, we send the item back to you safely, together with the calibration certificate.

Here you will find the right calibration service for you.

At the Hoffmann Group, new items can be ordered already calibrated. In this case, the new item will be delivered with a calibration certificate and, if you wish, registration for trendic® 3.5 measuring tool management. In addition to our new-item calibration and recalibration services in our calibration laboratory, we also provide an on-site calibration service for measuring devices, such as height gauges, measuring microscopes and torque wrenches.

What are the differences between factory Calibration and DAKKS Calibration?

In Germany’s largest calibration laboratory, it is not just DAkkS calibrations that are possible, but also factory calibrations.

In contrast to DAkkS calibration, factory calibration can only be traced back to the factory standard, and not to the national standard. As a result, on an international level, factory calibration is not recognised by every user.

Our accreditation by German accreditation body DAkkS allows you to have the greatest confidence in our services. We ensure our processes are reviewed on a regular basis and implement our measurement-related calibration processes properly, which means you can rely on your measuring results. The calibration guarantees traceability to the national standard. Sources of error such as hysteresis, repeatability and measurement deviation, as well as the expanded uncertainty of measurement and traceability are checked and documented. In terms of uncertainty of measurement, DAkkS calibration is, therefore, often more precise, more comprehensive and internationally recognised.

Advantages of DAkkS calibration:

- Very high reliability

- International validity

- Subject to state regulation

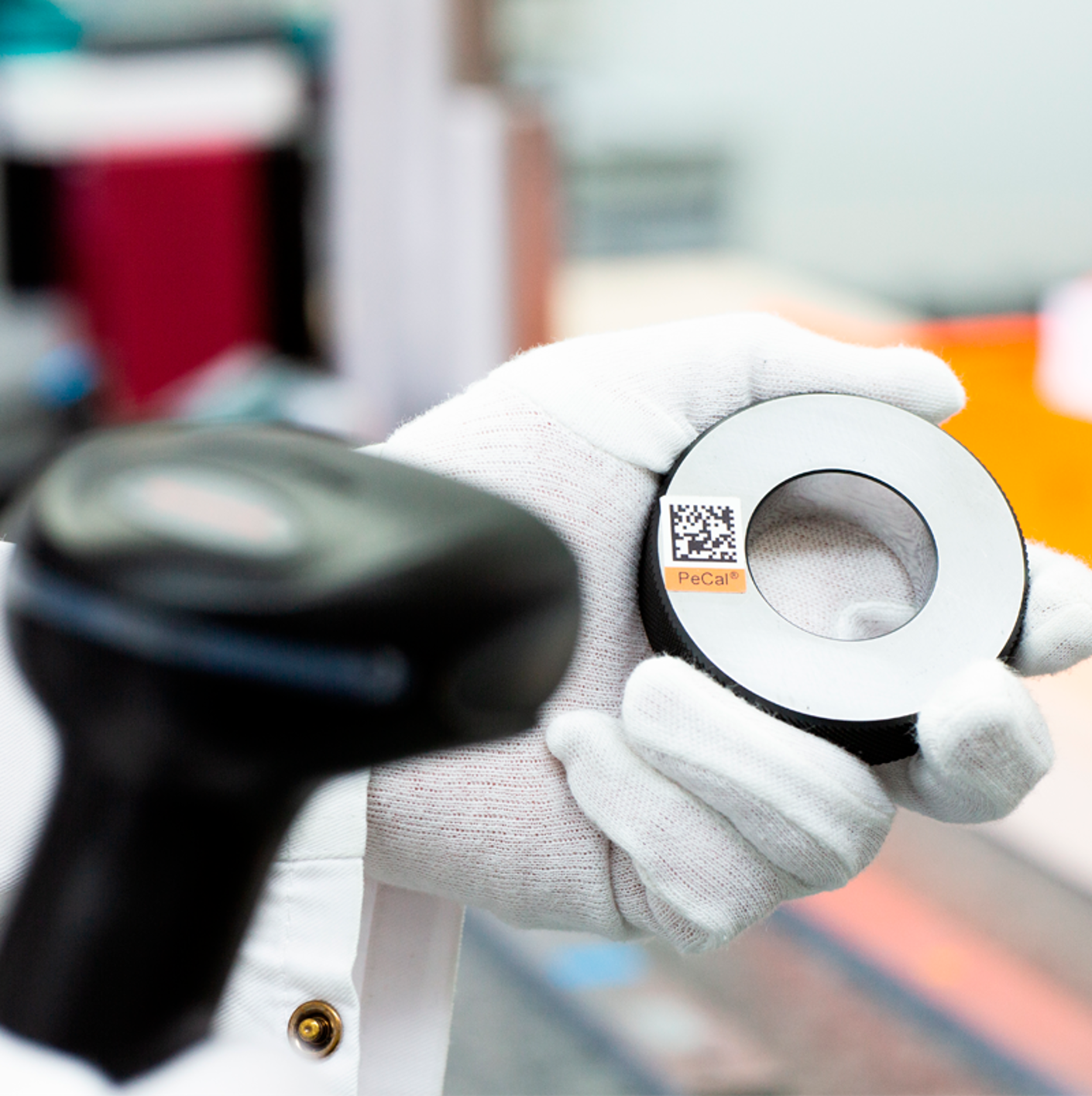

Manage measuring tools electronically

trendic® 3.5 – the new measuring tool management and calibration software – provides you with innovative possibilities. Through the use of a specially developed unique ID, measuring tools become “talking measuring tools” within the context of Industry 4.0. By scanning the code on a tool, trendic® 3.5 provides you with all the information about that particular measuring tool, which helps you to manage and observe relevant dates for the calibration work. trendic® 3.5 considerably reduces time and costs when it comes to measuring tool management.

FAQ

How often should measuring tools be calibrated?

It is usually up to the Quality Management department in a company to determine how often a measuring tool should be calibrated. As well as using cycles or frequency of use to determine the time of recalibration, it is advisable to have measuring tools calibrated after incidents, e.g. if they have been dropped.

When is DAkkS calibration necessary?

DAkkS calibration is necessary when the result of the calibration must be traceable to the national standard and be recognised on an international level. DAkkS calibration is also recognised in court. Furthermore, since September 2018, IATF 16949 prescribes DAkkS calibration for manufacturing activities in the automotive sector.

Consulting

The Hoffmann Group provides you with everything from a single source: from choosing the right measuring tool through to advice on calibration. Our metrology specialists will be happy to provide you with advice at any time.

Request consulting now

Request consulting now