Foot protection - Top protection with every step

Your employees’ feet require protective footwear

Over the course of a lifetime, a person will roughly walk the equivalent of four times around the world. Your feet support your entire body and – literally – carry heavy loads on a daily basis. For this reason, suitable footwear is important to protect the feet at all times, especially at the work place. Modern safety shoes provide protection without stressing the feet. An optimum fit and excellent wearing comfort increase well-being, the entire musculoskeletal system is relieved of stress and long-term injury is prevented.

Safety shoes are nowadays standard in pretty much all areas of both the manufacturing and service industry. Regardless of whether it is engineers, factory workers or logisticians – there is hardly any type of personal protective equipment (PPE) that is as widely accepted as foot protection. With the right products, work accidents can be avoided and safety at the work place can be increased.

Ideal foot protection prevents injuries caused by the following hazards:

- Physical: falling objects, crushing, penetration

- Thermal: molten metal splashes, heat, weather conditions, cold

- Electrical: touching live equipment, spark formation in dangerous areas due to electrostatic build-up

- Chemical: acids, alkalis, oils, greases, fuels

- Commuting accidents: twisted ankles, slipping, tripping.

- Long-term injuries: back and knee complaints

Work and Safety Shoes for various requirements

Foot protection can basically be split into two categories: Work shoes and safety shoes. The difference is in the toe protection cap, which used to be mostly made of steel and nowadays is also made from aluminium or high-grade composite materials. Safety shoes have a cap; work shoes do not. The latter variety therefore is primarily used in the medical professions, in gastronomy, in the police force and in the military. Safety sandals, shoes or boots offer a higher degree of protection. Both categories are split into various protection classes in order to meet the different requirements at the work place. Business safety shoes are a separate sub-category and come in elegant designs.

Discover the new GARANT comfort safety shoes

Our GARANT safety shoes offer more than "just" high wearing comfort and safety for your feet:

Uneven floors, a lot of walking and standing combined with badly fitting shoes in the medium term will damage health. Musculoskeletal disorders, in particular back pain withlong periods of absenteeism due to illness are often the consequence. With a view to your health, we put special emphasis on a wellthought-out development process for our new GARANT comfort safety shoes. The new shoe combines the highest possible wearing comfort with modern and timeless design.

Different widths and the special tweaked production technique permit a true multi-width system for different widths of feet.

A further feature is the exchangeable weight-dependent insole with damping module, which significantly reduces stress on the knee and back. Innovative and high-quality materials coupled with very high-quality workmanship guarantee very high protection combined with minimum weight. In short: The new GARANT comfort safety shoes offer you a stressfree walking sensation throughout the day - simply uncompromisingly comfortable.

Tool Tip: GARANT comfort safety shoes

In this video we would like to present our new GARANT safety shoe Comfort. The safety shoe guarantees you a high wearing comfort, high-quality materials and a well thought-out technology.

Well thought-out technology and high-quality materials

1. GARANT comfort heel-puller allows the shoes to be put on / taken off quickly and easily

2. Breathable functional lining

3. The material of the uppers is light-weight but hard-wearing micro-fibre

4. Toe protection cap of aluminium

5. Textile penetration protection, metal-free

6. Anti-slip outer sole GARANT comfort TPU

And of course: Protection against electrostatic discharge (ESD).

The right shoe for every foot

- Ideal solution for different shapes and widths of foot.

- Genuine multi-width system across all sizes.

- Various shank widths:

W1 for normal width feet, image on the left

W2 for wider feet, image on the right.

Continuous relief of the knees and back

- Insoles with integral damping module.

- Damping individually matched to the body weight of the wearer.

- 3 different hardnesses:

Green: soft, 50 - 65 kg

Yellow: medium, 66 - 85 kg

Red: hard, 86 - 120 kg

Furthermore, there are overshoes which offer adequate protection to visitors at a factory, for example, and can be simply pulled over one’s regular shoes. Accessories such as insoles, laces, boot liners and foot or shoe care products supplement personal protective equipment.

Do you have any questions? Our experts are keen to help you at any time:

Selection criteria for foot protection

What foot protection is required depends on which area an employee works in, which dangers he/she is subjected to and which legal requirements the employer has to comply with. Furthermore, wearing comfort, the material and heel shock absorption all play a role.

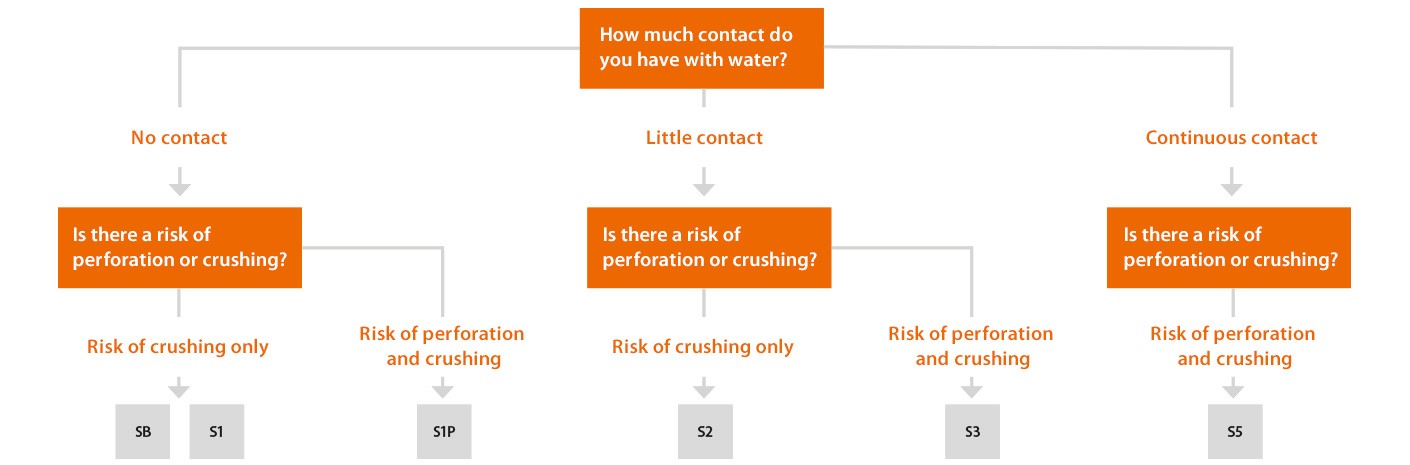

Find the right safety class for you

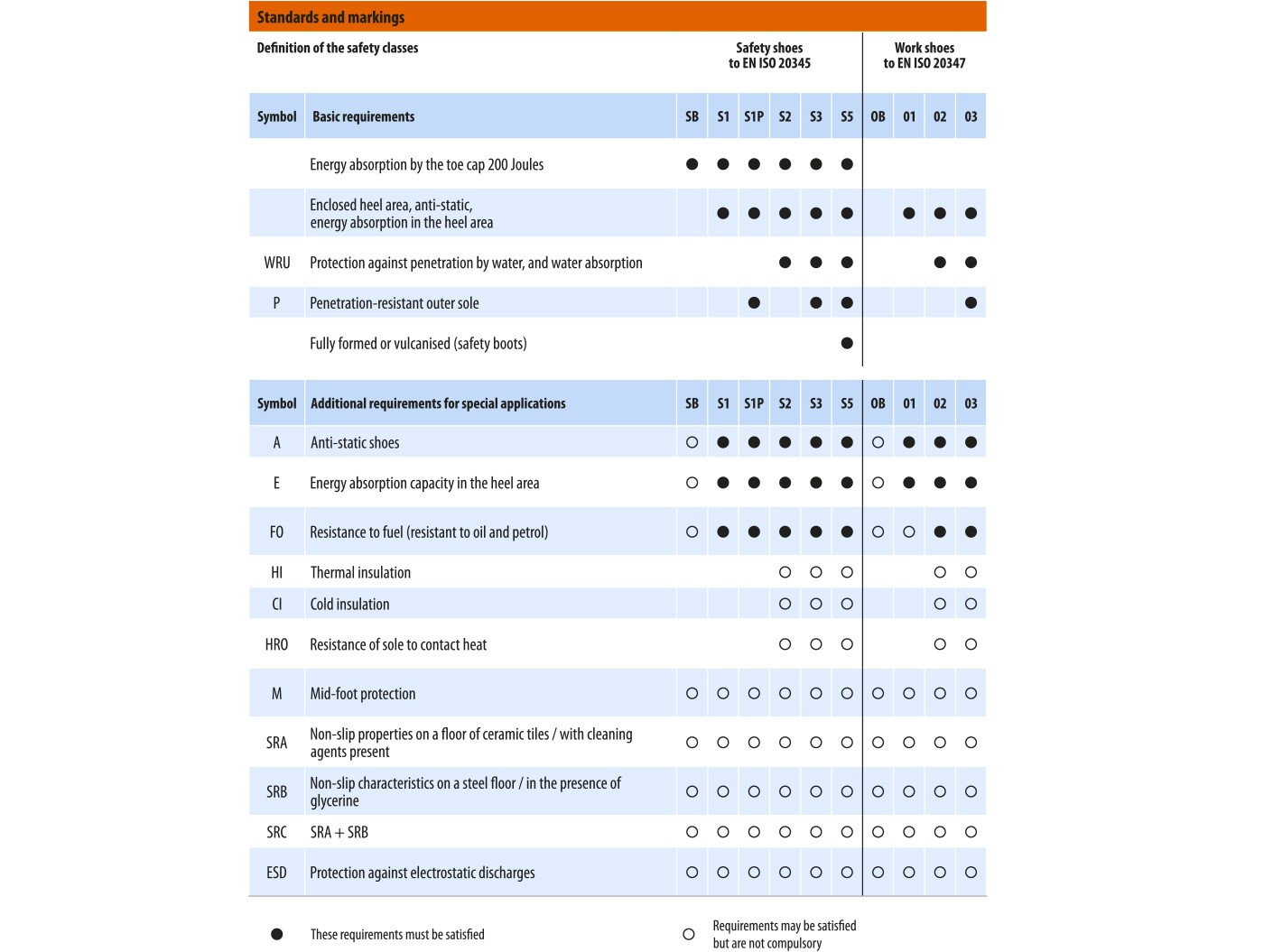

For work shoes, the following classes apply according to EN ISO 20347: 0B, 01, 02 and 03.

Safety shoes are divided into the following classes according to EN ISO 20345: SB, S1, S1P, S2, S3 and S5.

Class S3 safety shoes meet several requirements, which include the following:

- Energy absorption of the toe cap: 200 joules

- Closed heel area, antistatic, energy absorption in the heel area

- Protection against water ingress and water absorption

- Penetration-resistant outer sole

Depending on the model and design, work safety shoes may comprise further properties within one protection class. Exactly what those might be is specified by different abbreviations on the patch on the inside of the shoe: For example, “P” stands for puncture-resistant sole, and “SRB” for non-slip characteristics on a steel floor / in the presence of glycerine.

1. Toe protection cap

2. Penetration-resistant outer sole

3. Sole

Wearing comfort and fit

In order for employees to wear the foot protection during their working activities in accordance with regulations, wearing comfort and fit are of particular importance. Manufacturers of personal protective equipment have developed various technologies to meet this selection criterion. For example, the back can be given better protection using individual, weight-dependent heel shock absorption (1). A reduced sole thickness (2) or a modified geometry of the outer sole also relieve the musculoskeletal system of the wearer. Most manufacturers also offer models in different widths (3).

Breathable work and safety shoes are easy on the skin and ensure a pleasant sensation when wearing. The special GORE-TEX® technology is ideal for working outside, since it is watertight and simultaneously breathable. PPE specialists at Hoffmann are keen to assist you with choosing the ideal foot protection for the employees in your operation using tailored adjustments with product wearing tests right on your premises.

Sole types for work and safety shoes

A basic distinction is drawn between single-layer (mono) and double-layer (duo) soles.

Advantage of single-layer soles:

The special advantage of the single-layer sole is that a single material with a lower density can be sprayed on. This creates a lightweight sole which can easily adapt to the floor characteristics.

Advantage of double-layer soles:

With double-layer soles, two different materials with different properties can be used. For instance, the sole tread may be of rubber but the intermediate sole of polyurethane. This combines the benefits of both materials: the exceptional heat-resistance of rubber and the comfortable damping characteristics of polyurethane.

1 Rubber

Extremely hard-wearing, heat resistant for short periods up to 300°C; good resistance to cuts and abrasion.

Resistant to fuel, oil, microbes and a wide variety of chemicals. Heavier than PU and TPU and also somewhat less flexible when cold.

2 Nitrile rubber (perbunan)

Very hard-wearing. Heat resistant up to 220°C. Very good non-slip characteristics and excellent resistance to acids and alkalis.

3 Polyurethane (PU)

Heat resistant up to 130°C and flexible in cold down to -30°C. Resistant to oil and fuel, a wide variety of chemicals and microbes. Lighter than rubber soles. Good damping characteristics and pleasant to wear.

4 Thermoplastic polyurethane (TPU)

Similar to PU soles, but overall significantly better performance. Less abrasion means the soles last longer, and also increases the non-slip properties. In addition they offer even greater flexibility and optimised resistance to cold.

Special requirements for work safety shoes

Shoes with electrostatic discharge

Not only electrostatic charging and the protection of people play an important role in industry, but also the protection of parts and equipment due to controlled dissipation. The first aspect is covered by the requirement for antistatic footwear. For product protection, the ESD-capability of safety shoes is also required. The defined ESD range is ultimately a narrowing of the antistatic range from the safety standard EN ISO 20345.

Shoes are classed as ESD shoes when the electrical resistance of the person-shoe-floor system is below 3.5 × 107 Ω or 35 M Ω as per EN 61340-5-1. Here the lower limit of the electrical resistance is 0.1 M Ω and the upper limit is 35 M Ω (3.5 × 107 Ω). An ESD-capable shoe is thus also always an antistatic shoe. Important: ESD shoes are unsuitable for use by electricians and for working on live electrical equipment.

Work boots in winter

When working in the cold, safety shoes/boots should be sufficiently cold-insulating or lined, so that the feet stay warm. This increases not only wearing comfort but also protects against chill.

Foot protection with individual adjustment at the Hoffmann Group

The work and safety shoes included in the Hoffmann Group product range not only impress through their highly modern technologies and materials but also through their attractive designs. This includes work shoes , safety shoes for women and men in the form of shoes, boots and sandals , business safety shoes as well as fitting accessories for the foot protection of notable manufacturers. In this way, we are staying true to our mantra – Quality-driven since 1919: For us, quality and personal consulting are the top priority.

So that you can find suitable foot protection for your business and all your employees, our PPE advisers offer professional and personal foot measurements on site. In this process, the feet of every employee are measured individually and the right shoe model is allocated using these measurements. Next comes a wearing test. Feel free to contact our specialists about this, in person, by phone or via e-mail.

European Standards for foot protection

Safety and work shoes are subject to specific requirements. Safety shoes are regulated in EN ISO 20345 and work shoes are regulated in EN ISO 20347.

Frequent questions on work and safety shoes

Can foot protection be combined with any kind of insoles (e.g. lambskin soles)?

Only the shoe inserts offered by the shoe manufacturer are permitted. Otherwise they will deviate from their prototype version approved under the standard and may no longer offer the requisite protection.

What resistance does the toe protection cap offer against lateral stresses?

Only the shoe manufacturer of the model in question can answer this question, or the resistance must be analysed through appropriate tests. The reason for this is that, according to the applicable standards, impact and pressure perpendicular to the footprint and the remaining height under the toe protection cap are measured, but there is no requirement for lateral stress of the cap defined in those standards.

Are penetration-resistant inserts made from non-metallic materials really penetration-resistant?

Yes, if the prototype version was tested according to the relevant standard and the penetration resistance was confirmed. According to EN ISO 20344, the minimum force in the test process is 1,100 N. This equates to the force that a human weighing 80 to 90 kg exerts on the ground when walking. The tip of a 4.5 mm-thick test needle must not penetrate the test specimen. The test is considered to be passed if the tip of the test needle does not protrude through to the inside of the test specimen. This can be determined by means of a visual inspection and cinematographic or electrical detection.

Do you have any questions? Would you like to receive advice on PPE?

The Hoffmann Group provides you with everything from a single source:

- We provide individual advice, tailored to your needs

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Personal protective equipment also includes: breating protection, hearing protection, eye protection, hand protection, head protection, protective work wear, work clothing, fall protection and skin protection. This takes you to the overview.

Contact us now

Contact us now