Increased cost-effectiveness through modern clamping technology

How to optimise your work processes with clamps from the GARANT X family

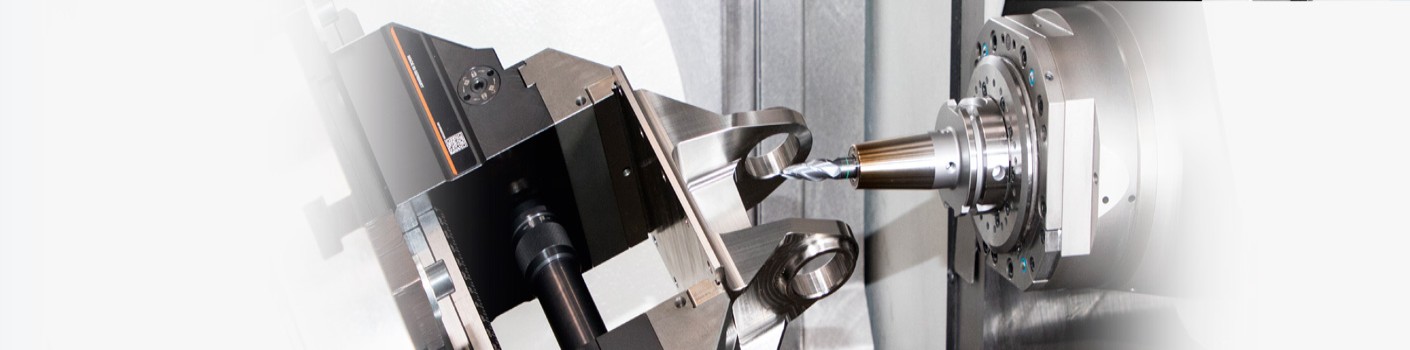

5-axis machines offer more safety in the production process than 3-axis machines. But even with 5-axis machines, there is still a risk of impacting on the tool. This raises the question: How can we solve this problem and increase the 5-axis machine’s efficiency at the same time?

This recorded webinar presents two clamps from the GARANT X family and explains why they offer far greater safety and flexibility than conventional clamps. The GARANT XTRIC and GARANT XPENT, for example, let you clamp two workpieces at once instead of only one, saving you time.

Once you have registered, you can access the recorded webinar directly on the landing page:

You’ll be learning about:

- Challenges when using a 5-axis machine and the GARANT XPENT as an innovative solution

- Why the GARANT XPENT offers maximum flexibility and safety

- How to save time and reduce workload with the GARANT XTRIC

The webinar “Increased cost-effectiveness through modern clamping technology” guides you through the design of the GARANT XPENT and GARANT XTRIC and shows you through practical application examples how these clamps can make your work process safer and easier. It also identifies optimisation potential for you to unlock through the use of zero point clamping systems.

Speaker: Robert Riesinger

Robert Riesinger has been an application technician in external sales for the Hoffmann Group since 1996. An expert in machining and clamping technology with more than 30 years’ professional experience, his primary focus is on technical innovations and clamping technologies of the future.