EYE PROTECTION – HIGH-QUALITY SAFETY GLASSES FOR YOUR EYES

Your eyesight is precious – protect it!

Around 85% of the impressions perceived by your senses are received by the eye. No other organ brings us so much information. It is all the more important then to protect our eyesight against any sort of negative influences. This includes hazards of a physical nature, such as solid bodies, dust particles, swarf and splinters. These can get inside the eye and cause irreversible damage to our vision. Chemical injuries such as burns are triggered by solid, fluid or gaseous substances, such as acids, alkalis, vapours and smoke. Furthermore, UV light, laser radiation, infrared and also visible light can cause visual impairments in the absence of adequate eye protection. There are also thermal hazards for the eyes posed by extreme heat and cold as well as risks of an electrical nature, such as the high temperatures when electric arcs occur during switching work.

Every year there are about 300,000 injuries to eyes in Germany alone. In order to prevent anything getting inside the eye during dangerous work, employees should always wear high-performance safety glasses. Only this way are they protected against different hazards so they can perform at their best.

Types of Eye Protection Glasses

Which safety glasses are the right ones primarily depends on the field of application:

- Safety glasses with side arms protect against physical dangers, such as in precision engineering work.

- Safety glasses with an integrated reading area enable precise detailed working.

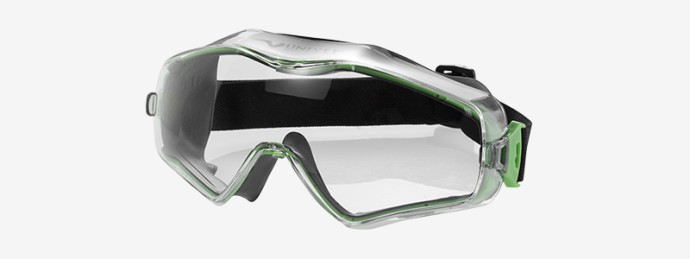

- Safety goggles prevent eye injuries of both a physical and chemical nature, such as during dusty work like grinding or laboratory work.

- Welder’s goggles offer optimum protection against thermal and optical hazards; for example during welding and soldering work.

Do you have any questions? Our experts are keen to help you at any time:

Selection criteria for eye protection

When choosing the right eye protection, the conditions at the specific place of work play a key role. In addition to the respective field of application, this includes:

- Light conditions: fluctuating, low, highly reflective light

- Work location: in enclosed rooms, outdoors, offshore

- Stability: without minimum strength, for impacts of various forces, for temperature fluctuations of –5 to +55°C

- Light filters: UV, infrared, sunlight

- Legal requirements: European standards for work safety

In order to take account of the respective conditions, work safety glasses are available in various tints with different levels of light transmission. Anti-reflective glasses, for example, offer the best-possible vision for working on brightly reflecting components without straining the eyes, as well as protection against physical dangers. Blue-mirrored safety glasses are ideal for use when working outdoors. They eliminate glare caused by the reflection of light from surfaces and also protect against physical hazards.

(1) Clear: For use in indoor areas, as protection against physical hazards (e.g. impact resistance).

(2) Yellow: Offers good vision and contrast under poor lighting conditions. Protection against physical hazards.

(3) AR – Anti-reflective: For optimum vision when working with brightly reflective components without straining the eyes. Protection against physical hazards.

(4) I/O – Indoor / outdoor: Ideal for use under fluctuating lighting conditions (indoors and outdoors). Reflects sunlight without attenuating it excessively. Protection against physical hazards.

(5) CBR – Contrast, Blue light reduction, Relax: The tinting has the effect of increasing the contrast, reducing the blue light and promotes relaxed vision. Protection against physical hazards.

(6) Grey: Well-suited for working outdoors, where harsh sunlight quickly strains the eyes. Meets the requirements for road traffic safety. Protection against physical hazards.

(7) Blue reflective: Ideal for use when working outdoors. Eliminates glare caused by the reflection of light from surfaces. Protection against physical hazards.

(8) Polarisation: For activities where there are distracting reflections of light from surfaces. Protection against horizontal glare and physical hazards.

(9) IR: Suitable for welding work. Protection against UV and IR radiation, and also against physical hazards.

The fit and comfort of wearing glasses also play a key role in making sure the employee actually wears them. This includes, for example, side padding, the option of side arm length adjustment and side arm inclination adjustment, as well as adjustable nose pads. Which type of glasses is required therefore depends on the specific requirements for personal protective equipment (PPE).

Eye protection for welding work

A dazzlingly bright light with strong UV radiation is produced during electrical welding work. Without adequate protection, there is a risk of burns to the conjunctiva and irreversible injury. Furthermore, depending on the welding technique, harmful substances can be released which can also get inside the eyes.For this reason, welder’s goggles must meet strict requirements for eye protection. They must repel glare while ensuring excellent vision, protecting against UV light, offering scratch resistance and employing a suitable material to prevent burn-in of welding sparks.

Product range and consultation at the Hoffmann Group

Since 1919 the Hoffmann Group has stood for the highest quality in professional tools. As system partner in the industry we use this expertise to offer our customers an exceptional product range in the field of eye protection. The complete range of safety glasses with side arms, safety glasses with an integrated reading area, safety goggles and welder’s goggles for all types of protection categories only comprises certified products from leading manufacturer brands. The HOLEX quality brand from the Hoffmann Group is also included here and offers an attractive price-performance ratio.

We provide personal consultation on protective equipment and support you in choosing your PPE – with solution suggestions, the right products and other consulting services. Get in touch with our highly qualified specialists, whether that be in person, by phone or via e-mail. We will provide you with professional support from risk analysis, product selection, wearing tests right through to training your employees.

European standards for safety glasses

In Europe, safety glasses, like all other items of personal protective equipment, are subject to the PPE Regulation 2016/425. The central standard in the field of safety glasses is EN 166. It stipulates all general requirements for personal eye protection; for example, areas of use, standards references, types of eye protection, general terminology definitions, correct labelling, etc.

Additional EN and EN ISO standards apply to eye protection depending on the field of application of the work safety glasses.

- EN 167: Optical test methods

- EN 168: Non-optical test methods.

The following additional standards may apply depending on the type of filter:

- EN 169: Filters for welding work

- EN 170 + EN 1836: Ultra-violet protective filters

- EN 171: Infrared protective filters

- EN 172: Sunlight protection for commercial applications

Frequent questions on eye protection

1. Are there special safety glasses for spectacle wearers?

As a business, you have the option of providing employees who have bad eyesight with special corrective safety glasses or over-specs. The former variety is a combination of safety and corrective glasses. You are only obligated to bear the costs for the protective part of this kind of eyeglasses. However, the investment will have long-term benefits. Employees will wear the corrective safety glasses all the time, which increases work safety. Also, the quality of their work will likely be better than when wearing corrective glasses and over-specs. In this case, the lenses can fog up or additional hazards may arise due to possible reflections.

2. When does an employer have to implement general compulsory wearing of eye protection?

This is the case if, despite having introduced organisational and technical measures to reduce hazards, there is still a danger posed to eyes, thus making suitable eye protection indispensable.

3. How do you prevent the lenses of work safety glasses from fogging up?

Currently, there is not yet an option for completely preventing lenses from fogging up. However, different manufacturers have developed various methods for the surface design of safety glasses, whereby they become less severely steamed up. Fog-free models in eye and face protection are indicated with the “N” symbol. Which design is best-suited can be determined with wearing tests in the respective critical areas.

Do you have any questions? Do you require PPE consulting?

The Hoffmann Group provides you with everything from a single source:

- We provide you with tailored advice

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Personal protective equipment also includes: breating protection, hearing protection, foot protection, hand protection, head protection, protective work wear, work clothing, fall protection and skin protection. This takes you to the overview.

Contact us now

Contact us now