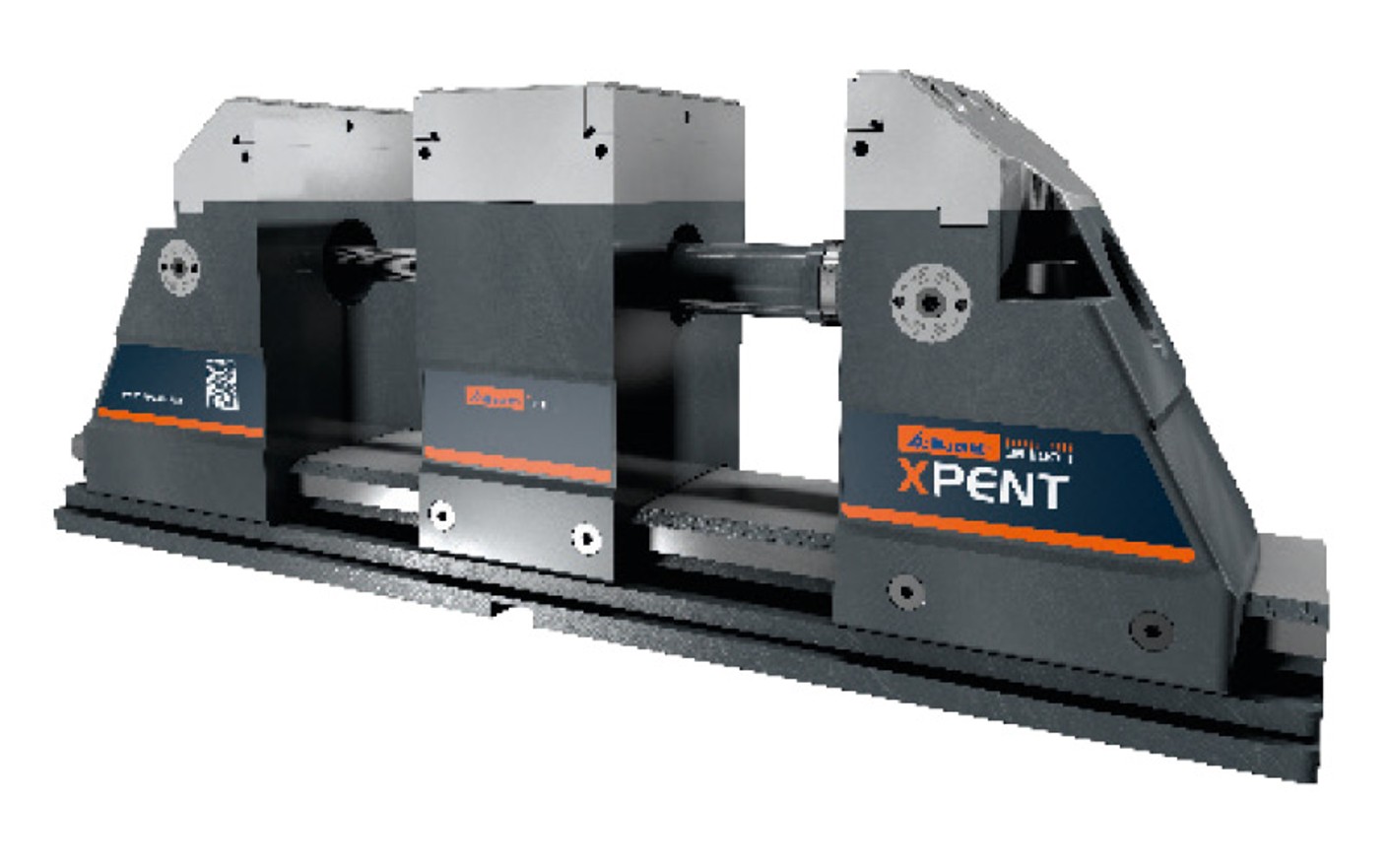

Revolutionary 5-Axis Vice

GARANT Xpent is convincing due to its perfect symmetry and very good accessibility

Welcome to a new dimension of vice:

With know-how and experience this new, unique clamping concept GARANT Xpent was developed in cooperation with our customers, in order to achieve optimum accessibility of the component.

The 5-axis vice is available in four heights:

- Size 0: More than 80 mm travel without conversion. Ideal for components from 6–168 mm; clamping ranges of up to 300 mm are even possible with conversion

- Size 1S: Ideal for 3-axis and 5-axis machines. 125 mm jaw width and a height of only 125 mm without top jaws.

- Size 1: More than 100 mm travel without conversion. Ideal for components from of 6–208 mm; clamping ranges of up to 380 mm are even possible with conversion

- Size 2: More than 100 mm travel without conversion. Ideal for components from 6–208 mm; clamping ranges of up to 380 mm are even possible with conversion

All components of the vice are perfectly symmetrical and case-hardened. The clamping modules can be reversed through 180°, thereby opening up a very wide range of flexibility.

(PDF)

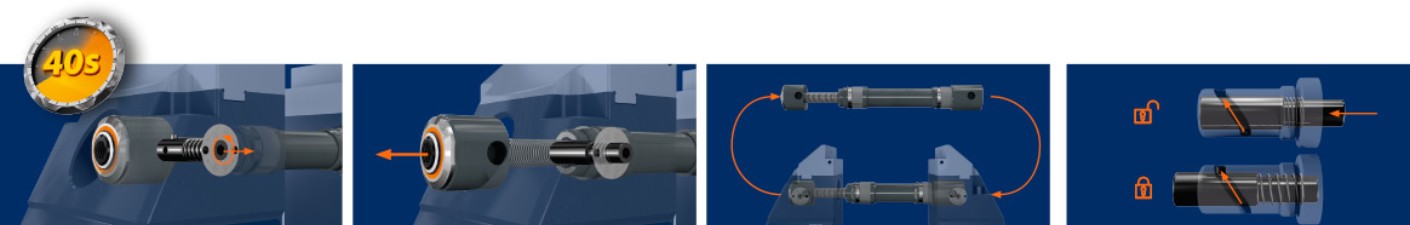

(PDF)Spindle change in 40 seconds

Spindel Quick Change (SQC) system

Disengage 2 locking pins per clamping module and pull the spindle out. Insert the extension spindle. Push the pins in against the spring pressure until they engage.

Extension of the spindle

Extension of the spindle length

Release the union nut by hand. (A spanner flat is provided in case a tool is needed to release the spindle.) Turn the nut back to the stop, insert the spindle extension and screw it in. Screw in the extension and make sure that the red security ring is not visible.

It is thus possible to change the clamping range within a very short space of time.

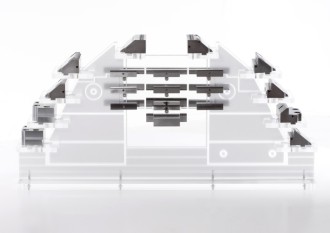

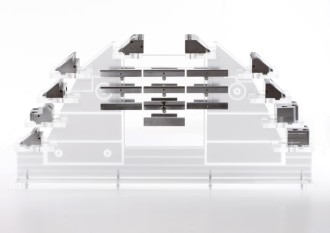

Individual multiple clamping

Take advantage of the middle jaw: Clamp 2 components at the same time. The components can have different sizes. Modules are flexible and can be slid individually on the base rail. Quick fixation of the middle jaw is achieved by clamping via 2 screws. Use two turned top jaws and increase your clamping range (ideal from a base rail of more than 550mm). For components of extremely different size simply use a combination of normal and turned top jaw.

Customer opinion

The company Berger Maschinenbau is a modern manufacturing company whose core business is machine tool building and automotive. The company has great experience in the fields of CNC milling and in assembling modules and machines. The GARANT 5-axis vice Xpent has satisfied all expectations: “The quick changeover of the clamping ranges, the wide choice of jaws and the optimum clamping force mean we can now achieve with one GARANT Xpent a range of jobs that used to require three other vices. The modular concept is really effective!”

Companies such as Hermle, DMG Mori or Alzmetall are already impressed by the wide range of clamping spans, the symmetry and the accessibility or the movement into the centre. "Optimum accessibility, flexibility in clamping, ease of operation and extreme stiffness - all this was an instant hit with us. At present it is the best 5-axis vice on the market." (Mr. Bozner, Alzmetall Technology Centre Manager)

Tools in Action-Video

5-axis vice GARANT Xpent in a practical test

The GARANT Xpent 5-axis vice demonstrates its exceptional accessibility when milling in 1.0503 / C45. Also in use: the GARANT TPC solid carbide mill and the Kyocera MFH mini high feed rate mill.

See more in our video!

To the flip catalogue GARANT Xpent

To the flip catalogue GARANT Xpent