Version:

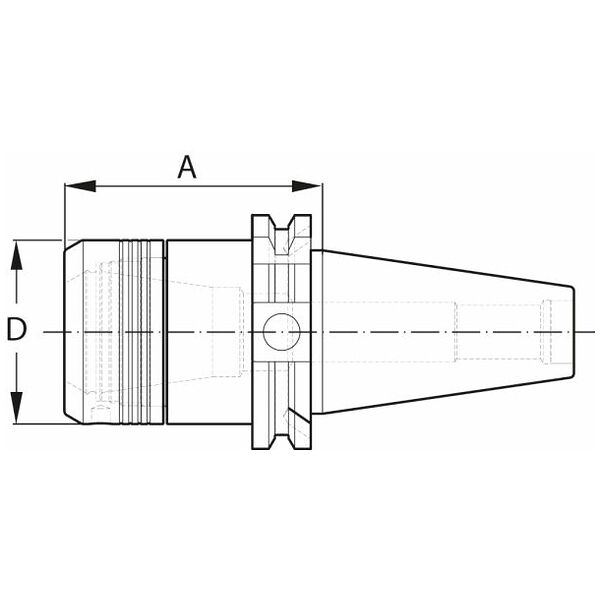

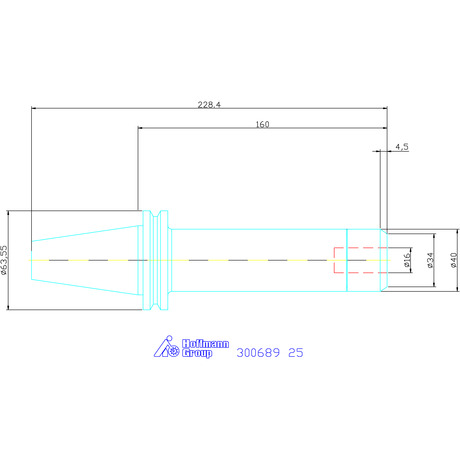

- Taper ground internally and externally with RFID/Balluffchip bore.

- Concentricity and repetition accuracy 3 μm at 3×D, maximum 50 mm when using a HP precision collet.

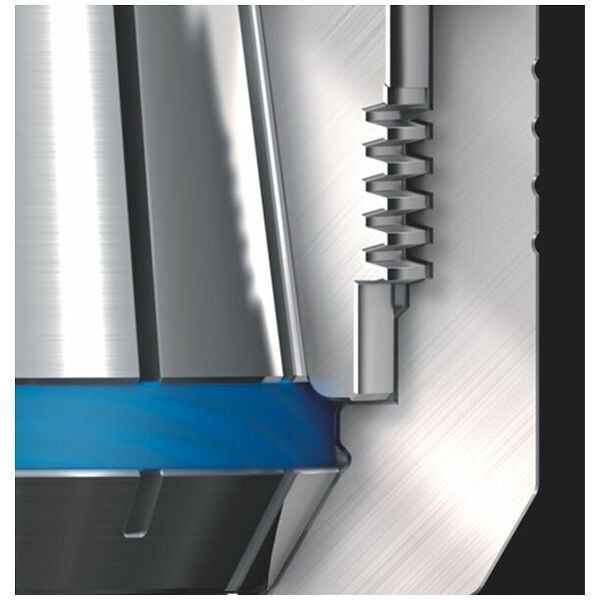

- HDC = Heavy Duty Chuck, a mount specially designed for rough machining. A reinforced chuck body ensures better stability and plenty of radial stiffness. Taper ground internally and externally. Ball-bearing clamping nut with trapezoidal-shaped fine thread for optimum tightening torques and clamping forces, reduces vibrations that occur.

- Very high clamping forces due to the collet fully seated in the chuck and coated clamping nut.

- Vibration damping due to the element collet and mass of the chuck.

- Alternatively for CENTRO P -> without seals, with ER clamping nut CP No. 309655 or sealed system with ER clamping nut CP for HP sealing rings No. 309665 in conjunction with HP sealing rings No. 309666 − 309668 (for internal coolant supply or as a dirt trap).

Advantage:

Patented optimum seating of the collet, double guides, trapezoidal thread and low-friction coated clamping nut amalgamate when clamped into a sturdy unit, thus ensuring a very high degree of rigidity and precision.

Application:

For high precision clamping of tools with plain shank. HDC especially well-suited for roughing (including TPC milling) and finishing operations and machining of high-tensile or tough materials.

Supplied with:

Without clamping nut.

Optional extras:

Note:

- Clamps only nominal ⌀ up to shank ⌀ tolerance h10.

- Use in combination with Fahrion collets.