Hand protection - the right choice for safe working

The hands as the most important working tool

The human hand is a perfect composition of 27 bones, 33 muscles and 30 joints. This complex construct can perform a wide range of tasks, from forceful blows to delicate precision work. Our hands are an impressive tool, yet unprotected they are exposed to many dangers.

More than a third of all occupational accidents are directly associated with injuries to hands. Possible injuries include cutting, burns and acid burns. Every accident is one too many and not only endangers health, but also causes high costs. The right gloves can provide effective protection.

Depending on the activity, different injuries occur which can be broken down as follows:

- Physical: Cuts, abrasions, blisters

- Chemicals: Burns, irritation

- Heat: Burns

- Cold: Frostbite, frost damage

Various types of hand protections

The varieties of work gloves are as diverse as the types of hazards. They can be broken down as follows:

1. According to material:

- Leather gloves

- Cotton and knitted gloves

- Work gloves made out of synthetics (e.g. polymer, polyacrylic)

2. According to field of application:

- Welder’s safety gloves

- Work gloves for dry areas

- Gloves for oily and moist/dry areas

- Cut-resistant gloves

- Special safety gloves

- Heat protection gloves

- Cold protection gloves

- Electrician’s safety gloves

- Chemical protective gloves

3. According to duration of use:

- Disposable gloves

- Multi-purpose gloves

In order to be able to know exactly which protective glove is to be worn for which activity in operations, we use what are referred to as glove plans.

The PPE specialists of the Hoffmann Group are keen to help you with creating a customised plan for your company.

Selection criteria for protective gloves

There are a large number of criteria that must be taken into consideration when choosing the best-suited work gloves. The field of application is of particular importance. Is the environment dry, or is it more of a damp and oily work place? Do the gloves need to allow delicacy and precision for the respective activity, or do they need to help with heavy work? Which hazards do the gloves need to protect against?

In order to fulfil these varied demands, work gloves are made from a wide range of materials. Wearing comfort also plays an important role when choosing. For example, there are latex alternatives for those people who suffer allergic reactions to this material.

Hand protection categories as per PPE directive

Every work glove corresponds to a particular category of the Personal Protective Equipment (PPE) Directive:

Category I includes gloves in a simple design for the protection against minimal risks; for example, household gloves.

Work gloves of a mid-level design for mid-level risks, such as protecting against cutting injuries, belong to Category II. They must bear a CE mark.

Category III includes hand protection which guards against fatal risks or irreversible injuries which could be caused by chemicals, for example. These models must also be tested and certified by an accredited certification body. Furthermore, the quality assurance methods used by the manufacturer which guarantees the homogeneity of its production or checks the uniform quality of the end product must be inspected by an independent body.

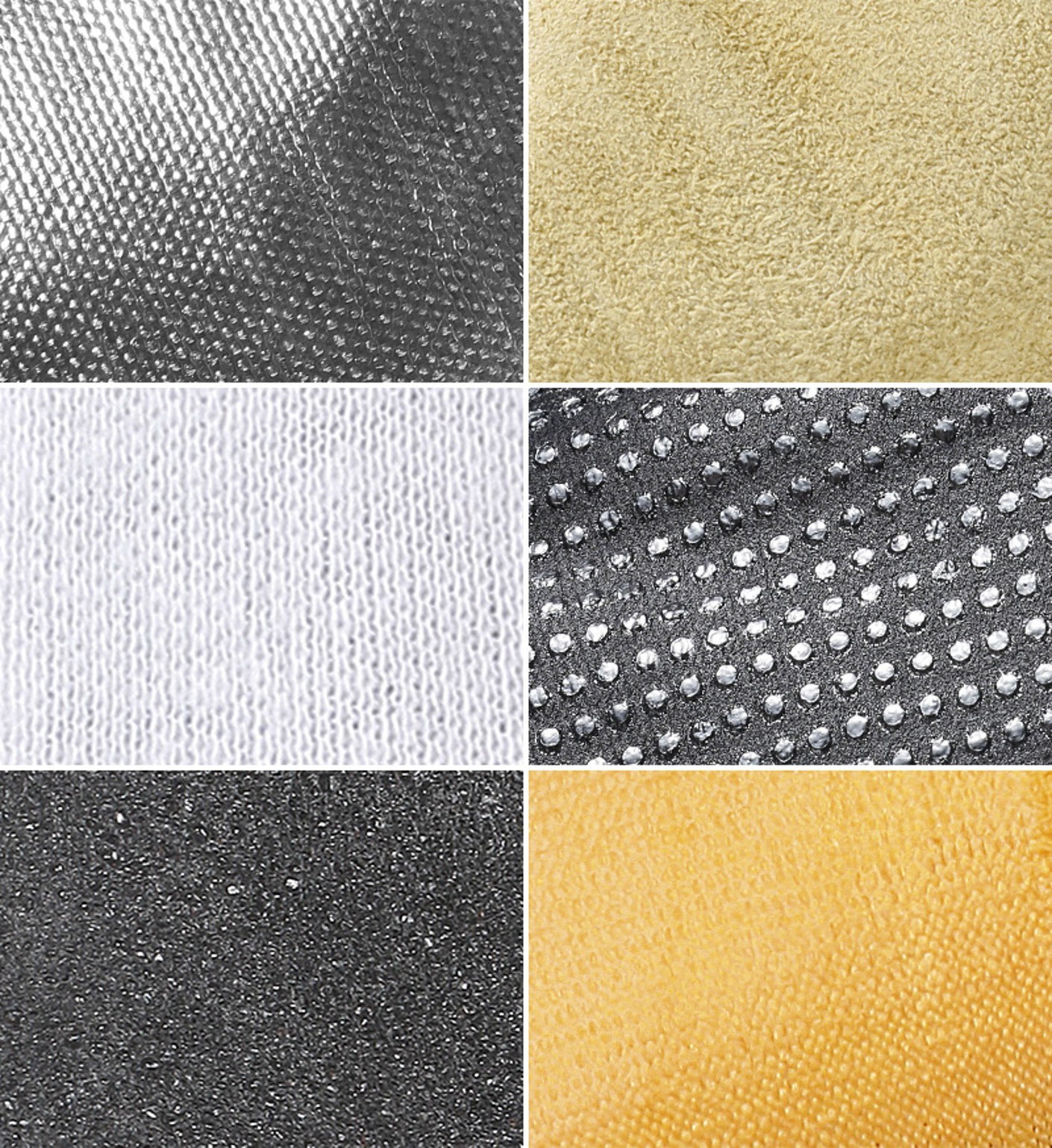

Different materials

The material of the work gloves is closely associated with the respective field of use:

Cotton, for example, is a natural material which is easy on the skin, absorbent, heat-resistant, durable, hard-wearing and elastic. Uncoated cotton gloves are used for dry, light work and as liner gloves.

Polyamide is a synthetic fibre which was originally developed as a substitute for silk. The material is highly elastic, wear-resistant, durable and relatively resistant to chemicals. For multi-purpose gloves, it serves as the leading backing material, which can be combined with different coating materials.

Latex originally referred to the milky sap of the rubber tree. Today the term is also used for natural rubber or rubber. Latex is not resistant to oil.

There are a great many more materials for work gloves, such as aramid, butyl, glass fibre, nylon, polyurethane, nappa leather or nitrile. Key to making the right choice is the combination of backing material, knitting technology and the type and thickness of the coating.

Special areas of application for protective gloves

Handling chemicals

Anybody whose job involves handling chemicals must take special precautionary measures. Dangerous gases or vapours are ingested through the nose and mouth 60 per cent of the time. This means suitable breathing protection is required. However, up to 30 per cent of chemicals enter the human organism through the skin or mucous membranes and can cause irreversible damage.

This is why the PPE Directive prescribes special chemical protective gloves. They consist, for example, of butyl or chloroprene.

Depending on the field of use, they must protect against the chemicals both penetrating and permeating. Penetration refers to chemicals or microorganisms entering into the glove material at the macrosopic level through porous points, seams, pinholes or other defects in the glove. Permeation poses the threat of chemicals entering and seeping through intact glove material at the molecular level. The time after which the hazardous substance makes contact with the skin is called the breakthrough time.

Hot/cold protection gloves

Protection against heat

If employees are subjected to thermal risks such as heat or flames or extreme cold in the course of their duties, the gloves must protect them adequately against these dangers. Special gloves as per EN 407 protect against inflammation, contact heat, convection heat, radiated heat and against molten metal – to a performance level 0 to 4 in each case.

Protection against cold

It is similar for protective gloves against cold. In accordance with EN 511, the properties include convection cold resistance, contact cold resistance and water resistance. Performance levels 0 to 4 apply to the first two criteria; for water resistance, there is only a distinction between 0 (water penetration) and 1 (no water penetration).

Protective gloves for welding work

High temperatures and radiated heat arise during welding work. Special welder’s gloves are required to adequately protect the hands. They are considerably longer than other work gloves in order to offer the wrist and the lower arm protection as well. These gloves can also be combined with welder’s hand protection, which provides extra protection against heat and radiated heat.

High quality products and personal consulting from the Hoffmann Group

The diversity of gloves on the market is virtually unlimited. We have selected the best gloves of the leading brands for you. In doing so, we abide by the long-standing demands of the Hoffmann Group for top quality.

Individual glove plan for perfect safety at work

Furthermore, tailored support for our customers is a key focus for us. Our highly qualified team of PPE specialists will provide you with personal advice on the subject of personal protective equipment. We are at your side, whether that be in person, on the phone or via e-mail.

Our professional consulting services also include the devising of customised glove plans: Listed in it are all the protective gloves which are required on your premises based on a risk analysis. This means you and your employees have a quick overview of which type of gloves they have to wear for various tasks.

Take advantage of our expertise in the field of PPE garnered over decades: We will provide you with professional support from risk analysis, product choice, wearing tests right through to training your employees.

Special regulations regarding hand protection

The basic requirements for protective gloves are regulated by DIN EN 420. This standard defines the relevant test methods to be applied for all protective gloves and the following requirements:

Principles of design

- Glove manufacturing

- Resistance of the glove material against water penetration

- Harmlessness

- Comfort

- Performance

- Labelling to be provided by the manufacturer

- Information to be provided by the supplier

Furthermore, there are special product standards that are applied in conjunction with the general standard:

- EN 388: Protection against mechanical risks.

- EN 407: Protection against heat

- EN 511: Protection against cold

- EN 374: Protection against chemicals and microorganisms

- EN 12477: Protection against heat and mechanical risks during welding

Frequent questions on work gloves

How often do work gloves need to be changed?

Where chemical protective gloves are concerned, you must pay attention to the prescribed duration of use. After a certain period of time, the glove will be permeated with the chemical product thus losing its protective function. If a work glove shows signs of damage, it should be replaced immediately. It is also worth wearing several suitable gloves in alternation over the course of a day. This reduces the softening of the skin caused by permanently sweating inside a glove. Protective gloves that are stored away dry out in the meantime.

Can disposable protective gloves sufficiently protect against chemicals?

In general, disposable protective gloves are not chemical protective gloves. For example, they cannot be used for cleaning in hospitals. However, there are individual products of this category on the market which offer limited protection to chemicals. They are indicated with a “beaker glass” or an “Erlenmeyer flask”. The underlying tests relate only to certain chemicals, however. For this reason, it is worth checking exactly which substances these disposable gloves protect against. Disposable gloves should be used for splash protection and be disposed of immediately in the event of contact with a potentially hazardous substance.

Where is the correct chemical protective glove noted in the safety data sheet?

Point 8 of the safety data sheet contains specifications regarding personal protective equipment and at a minimum should provide information on suitable glove materials and the minimum thickness of the material. If the method of processing the product is known, according to legislators, the manufacturer of the chemical product should cite a glove product as specifically as possible.

If the specifications in the safety data sheet are not conclusive, you can ask for help from the chemicals manufacturer, the manufacturer of the protective gloves, the relevant social accident assurance association or the PPE specialists at the Hoffmann Group.

Do you have any questions? Would you like to receive advice on PPE?

The Hoffmann Group provides you with everything from a single source:

- We provide individual advice, tailored to your needs

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Personal protective equipment also includes: breating protection, foot protection, eye protection, hearing protection, head protection, protective work wear, work clothing, fall protection and skin protection. This takes you to the overview.