The perfect tool for you. This is GARANT – for the last 50 years.

GARANT: My tool. My system.

Our GARANT tools are the perfect tool system for you. You could almost believe they were made for you. Our ability to customise our tools in this manner results from developing our tools in collaboration with users, suppliers and 12 of our technology centres. This approach enables us to create sophisticated, reliable tools that make work fun for you because they help you tackle daily challenges. Making work effortless, with excellent results.

And we even go one step further: our tools dovetail with one another intelligently and work as a system, which will help to make your processes quicker. You're guaranteed to be impressed!

GARANT is a tool system with a fun factor. Simply enjoy the performance and high quality.

GARANT. Built for work.

The GARANT is a real favourite – a tool as strong as you. There are two main roles in our new image film – one for GARANT tools and one for the users. It's teamwork at its best!

GARANT - our promise of quality

We promise quality. You benefit.

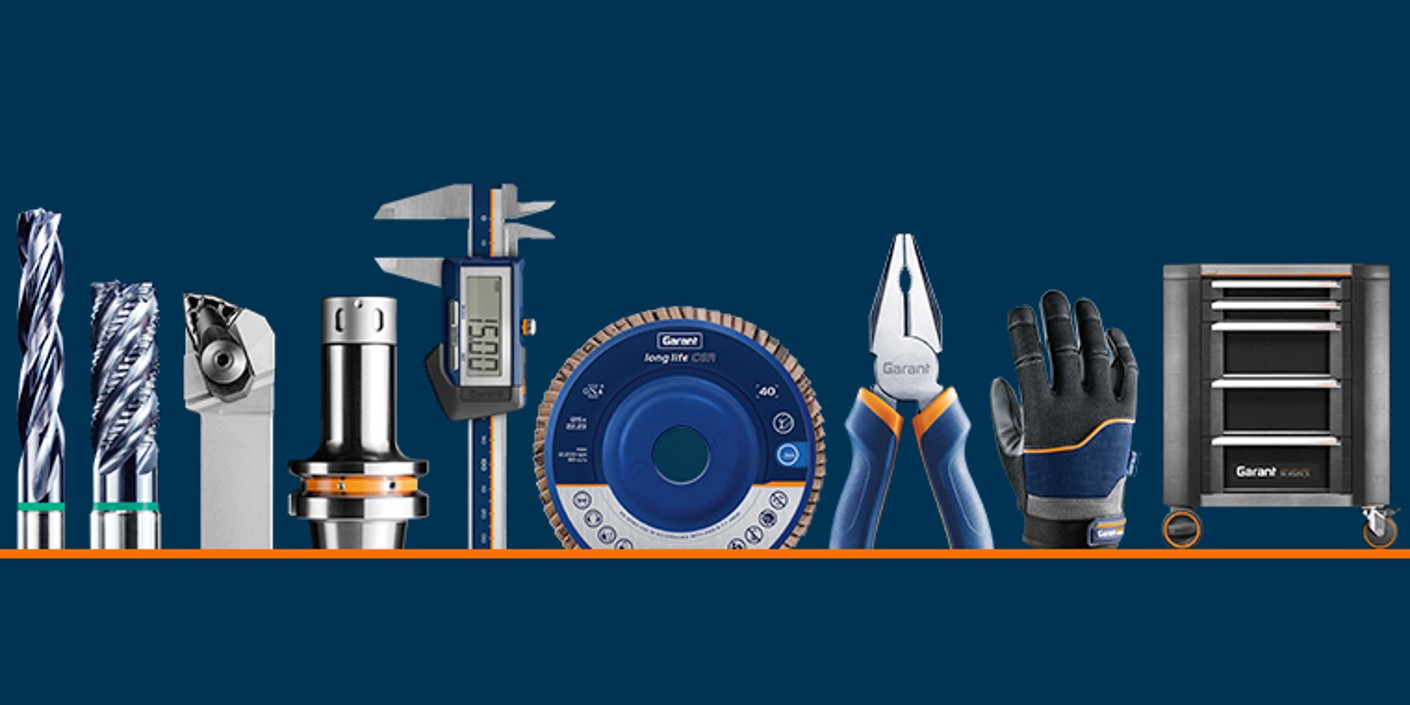

GARANT is THE system tool you need for everything falling within 10 metres of industrial workstations – with reliable high quality. You benefit from: optimum availability, efficient service and increased productivity – everything from one supplier.

GARANT quality includes:

- More than 55,000 GARANT products from application areas such as machining, clamping technology, hand tools, workstations and storage and more

- Our in-house development team, twelve in-house technology centres and certified test methods

- Production at the world's best production facilities

- Excellent price-performance ratio

- 10-year warranty on GARANT products*

* 10-year warranty on materials and manufacture of GARANT products when used as intended, excluding regular wear as a result of mechanical stress and excluding all electronic components.

* 10-year warranty on materials and manufacture of GARANT workstations and storage products when used as intended, excluding regular wear as a result of mechanical stress and excluding products installed in containers as well as all electronic components.

An outstanding partner to help you work professionally every day.

We want to be able to offer you added value and quality – that's why we never stop working and are continually refining and optimising our products and services. We always ensure you and your needs are at the heart of our work, and we draw on any insights we have gained from discussions with users. Our quality management system has been recognised as one of the best and we are certified as a manufacturer to VDA 6.4 and ISO 9001. There is something else we're also very proud of: our 50+ international awards, such as the iF Design Award, the German Design Award and the Red Dot Award.

Why not take a look at our other campaign clips too.

Why not take a look at our other campaign clips too.