GARANT Power Tang: Concentrated power for perfect results

The GARANT Power Tang: 90° tangential high-performance face/end mill

The face/end mills offer impressive cost-effectiveness due to the 4-cutting edge concept. High feed rates and maximum cutting depths permit an extremely high metal removal rate, leading to increased productivity. Perfect surfaces are achieved with face milling, and the exceptionally stable bedding of the indexable inserts guarantees highest process reliability.

Advantages at a glance:

- 90° accuracy

- Reduced cutting forces

- High metal removal rate

- Increase in productivity

- Powerful, efficient, precise, reliable.

A suitable tool for every application

Your machining task – our tooling solutions:

LO.U13

GARANT Power Tang with bore, single-row, 215122, d. 40 - 125 mm, ap max 12mm

GARANT Power Tang with bore, multi-row, 215126, d. 50 - 100 mm, ap max 47-81mm

LO.U09

GARANT Power Tang with plain shank or Weldon shank, single-row, 215950 – 215956, d. 16 – 32 mm, ap max 8mm

GARANT Power Tang with thread, single-row, 215960 – 215962, d. 16 – 32 mm, ap max 8mm

GARANT Power Tang with bore, single-row, 215966 – 215968, d. 40 – 63 mm, ap max 8 mm

GARANT Power Tang with thread, multi-row, 215974, d. 25 – 32 mm, ap max 32 – 39 mm

GARANT Power Tang with Weldon shank, multi-row, 215972, d. 25 – 40 mm, ap max 39 – 47 mm

GARANT Power Tang 90° tangential high-performance indexable end mill stands for concentrated power and best results.

GARANT Power Tang is powerful in every application and every material, whether side milling, face milling, corner milling or slot milling.

See more about this subject in our video!

High-tech, design and efficiency combined

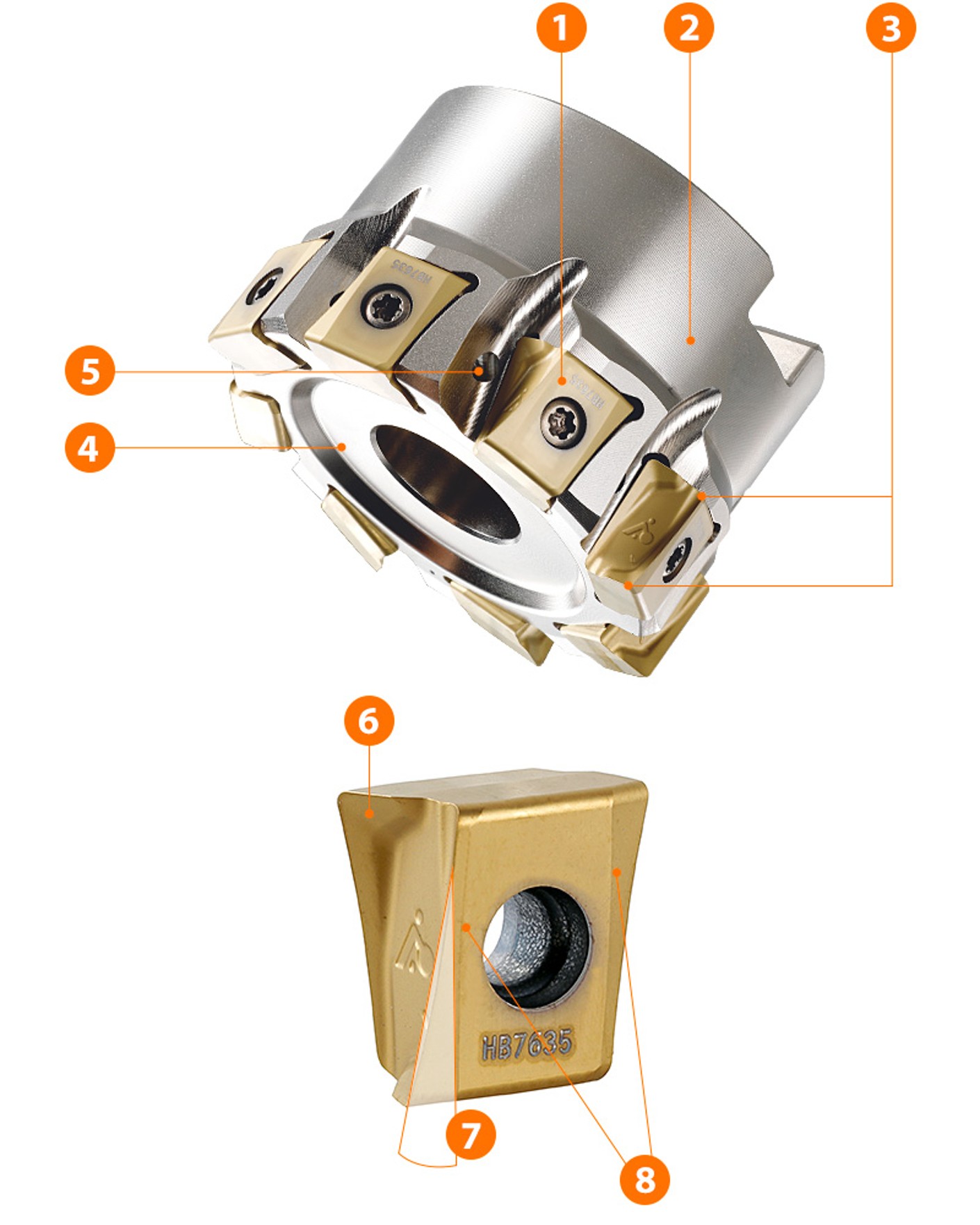

Physical limits redefined. Tangentially oriented inserts for maximum performance and process reliability.

- Strengthened core due to tangential positioning of inserts: Increased stability. Vibration damping.

- Optimised bedding of indexable inserts: Reduced tensile force in the axial direction. High security of seating in the direction of force.

- Through-coolant supply: Optimum cooling of the cutting edge. Outstanding chip clearance.

- Ni-coated carrier: Increased wear resistance.

The uniqueness is in the detail

Tangentially oriented inserts stand for geometries which reduce cutting forces, best surface qualities and substrates of the latest generation.

- Higher security of seating in the direction of the cutting forces due to tangentially oriented inserts

- Ni-coated carrier for improved wear protection

- Cutting depth LO.U 13 = 13 mm

- Through-coolant supply

- Increased stability due to strengthened core

- Flat chamfer for high surface qualities & concave cutting edges (reduction of cutting force)

- Positive axial rake +10°

- Four cutting edges for higher cost-effectiveness

Customer reference

KAPP NILES is one of the leading manufacturers in the world of grinding machines and tools for precision machining of gear teeth and profiles. Together with the associated high-precision measurement technology it provides production solutions to its partners. Technologies from KAPP NILES guarantee both precision and cost-effectiveness to an equal degree, for production of highly demanding components. KAPP NILES delivers precise movement into customers’ projects – on land, at sea and in the air.

GARANT Power Tang - Milling test at KAPP NILES

Machine: Hermle C50U 60 KW spindle power

Material: 16MnCr5 / 1.7131

Carrier: 215122 63 / 6; insert: 215136 ST1400

Results: Vc = 225 m / min, fz = 0.3 mm, ap = 7 mm, ae = 41 mm, spindle power = 40%