{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

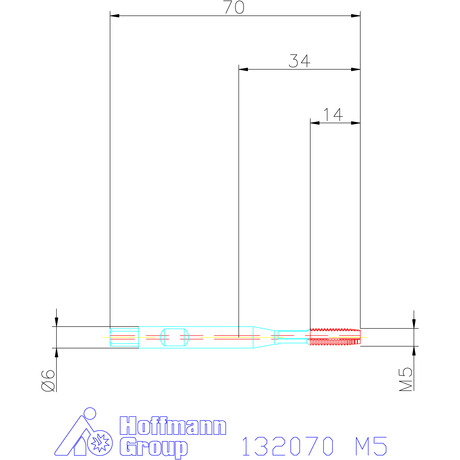

| Thread size | M5 | |

| Coating | TiAlN | |

| Thread type | M | |

| Flank angle | 60 degrees | |

| Tool material | HSS E PM | |

| Standard | Manufacturer’s standard | |

| Thread standard | DIN 13 | |

| Tolerance class | ISO 2X 6HX | |

| Taper lead form | B | |

| Shank | DIN 1835 B with h6 | |

| Through-coolant | yes | |

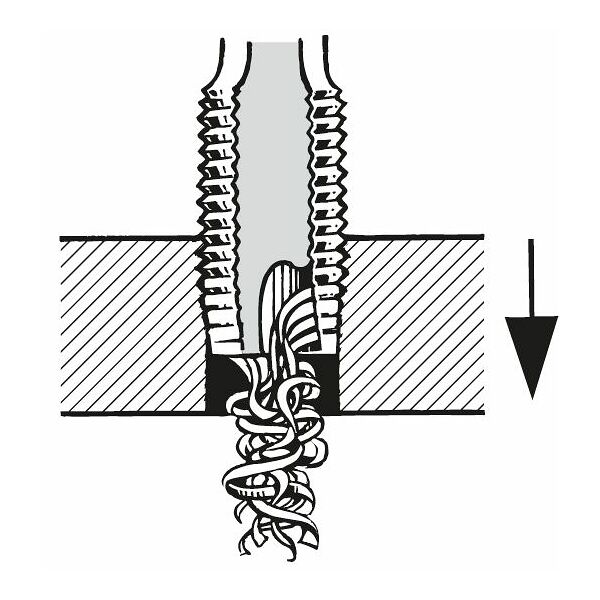

| Application for type of drilling | up to 2.5×D for through holes | |

| Cutting direction | right-hand | |

| Thread pitch | 0.8 mm | |

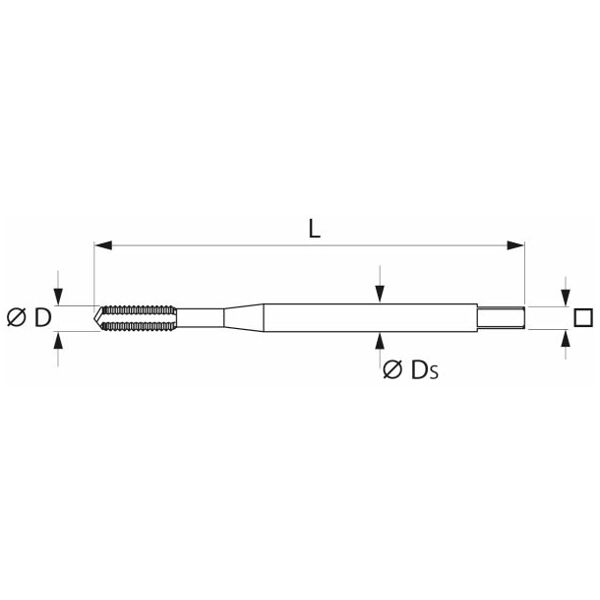

| Overall length L | 70 mm | |

| Shank ⌀ Ds | 6 mm | |

| Shank square □ | 4.9 mm | |

| Tapping hole ⌀ | 4.2 mm | |

| Thread ⌀ | 5 mm | |

| Shank tolerance | h6 | |

| Type of threading tool | Machine tap for synchronous machining | |

| Number of clamping slots | 3 | |

| Colour ring | red | |

| Number of cutting edges Z | 3 | |

| Thread depth | 12.5 mm | |

| Type of product | Tap |

| Article number | 132070 M5 | |

| Manufacturer number | 132070 M5 |