Putting an end to laborious and long set-up times for milling operations.

"ZeroClamp is an important, indispensable part of our production!"

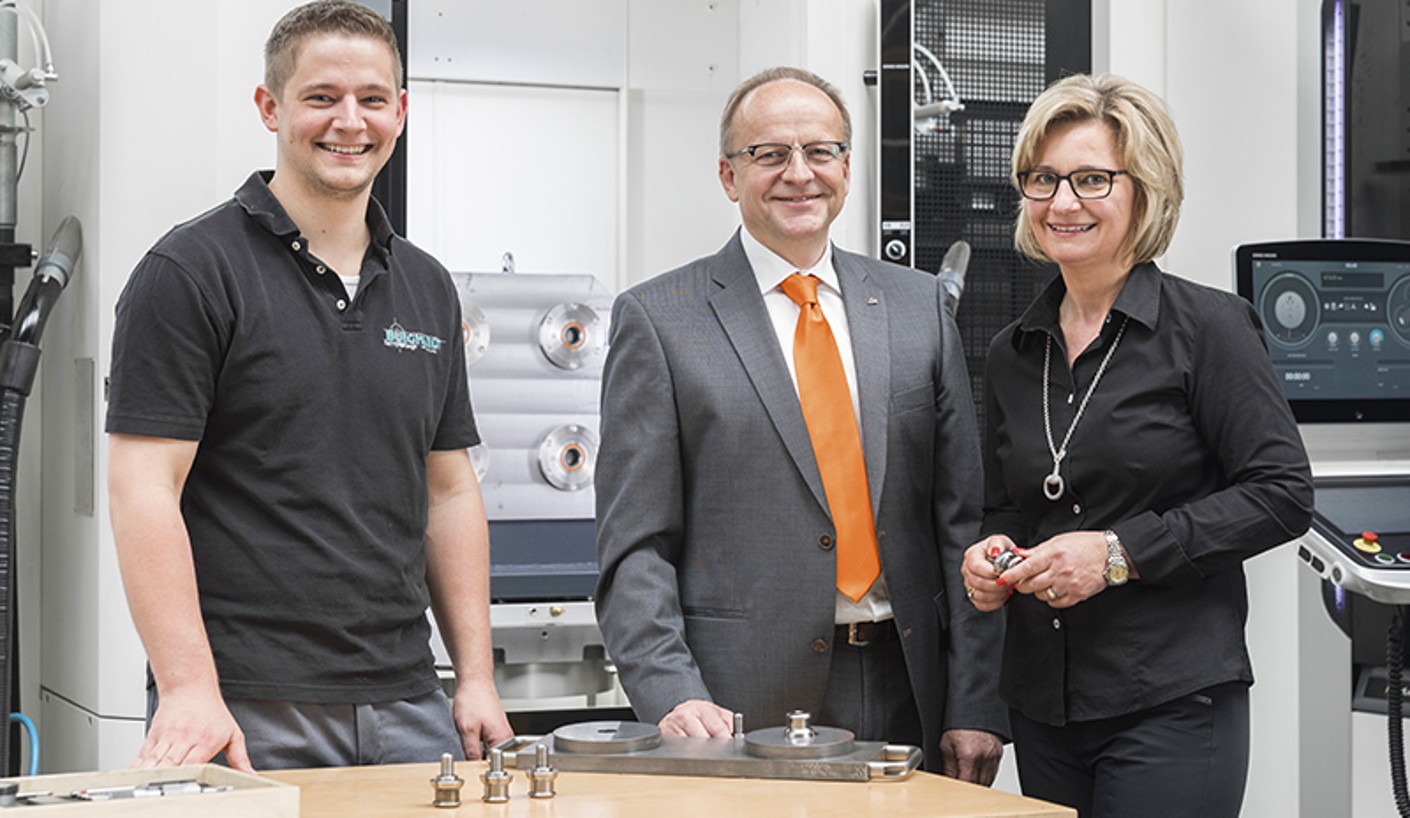

As a contract manufacturer, we here at BURGHARDT Zerspanungs GmbH & Co. KG are constantly faced with the challenge of keeping set-up, changeover and non-productive times to a minimum. Turning, milling, grinding, drilling and measuring are a regular part of many of our Hessian, family-owned company's pro-duction orders. Our customers include manufacturers of packaging and special machines, as well as suppliers of door systems, for whom we frequently produce elaborate small series or individual parts.

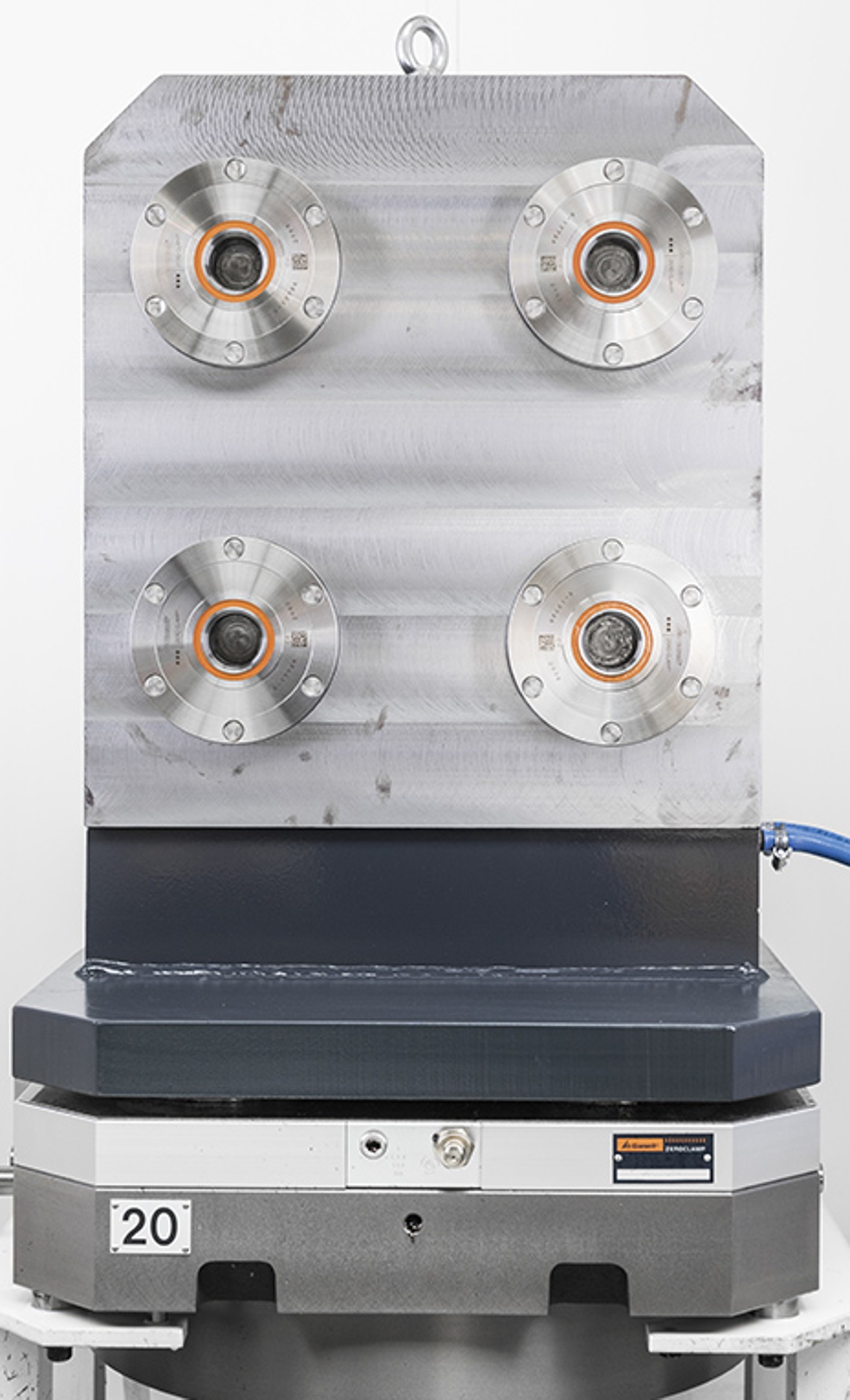

"We continually invest in modern machines and factory equipment to guarantee and further enhance our high standard of service", explains Managing Partner Tanja Siebert. That is why, in the first quarter of 2016, a flexible manufacturing cell with two horizontal machining centres and a 24-station pallet pool was put into operation. It is here that the GARANT ZeroClamp zero point clamping system is used primarily for milling. Qualified support was given right from the start of the purchasing process by application engineer Jeannette Arndt-Hoffmann and account manager Andreas Rosengarten of Perschmann, the regional Hoffmann Group partner. We have been collaborating and putting our trust in the tool specialist for more than 20 years.

We were able to get a personal impression of the product before purchasing it when we were taken on a visit to the manufacturer ZeroClamp in Icking. What we particularly like about the GARANT ZeroClamp zero point clamping system are the high clamping forces, the individual production which took into account our requirements, the easy handling, excellent positioning and repeatability, as well as the low maintenance requirements. In the past, we used conventional vices and T-slot plates for clamping.

The components had to be aligned by hand and remeasured. Now we can position the components with high precision and quickly dock on processing devices. This does not only save time on a daily basis, but also ensures high process reliability. "At the end of the day, the clamping system has to work reliably at all times and that's what it does. We have not had any malfunctions", says Nico Siebert, studying for a Masters Degree in Mechanical Engineering and prospective 3rd generation company successor.

By investing in the new system the productivity of our production has increased significantly. ZeroClamp is an important, indispensable part of this process. We are very grateful for the continuous solution-oriented approach and advice by Hoffmann Group Perschmann.

BURGHARDT Zerspanungs GmbH & Co. KG – Your precise partner for machining tasks

Our family-owned company BURGHARDT Zerspanungs GmbH & Co. KG has a large, ultra-modern pool of machinery amounting to more than 2,000 square metres at its disposal. Since 1974 we have been specialised on turning, milling and grinding of workpieces. We attach particular importance to quality and delivery reliability. From our base in Northern Hesse we supply customers all over Germany with components of varying complexity. We employ approx. 40 specialised staff who work on our machining centres, CNC lathes, grinding machines etc. to produce individual solutions for our customers, either as one-off items or in series production. All workpieces undergo stringent quality controls.