Version:

3-flute drill, specially developed for

use at very high feed rates. Outstandingly suitable for machines with

high installed power and stable machining conditions.

- Special cutter geometry with stable cutting edges and large clearance at the centre enables very high feed rates.

- The patented tip is optimised for chip flow and generates low cutting pressure with good chip breakage.

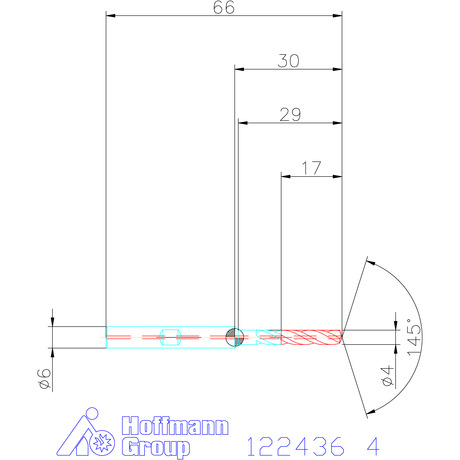

- With a 145° point angle for low burrs on emerging from through holes.

The

sector-leading technology of the chisel point guarantees

optimum self-centring behaviour and permits

spot drilling on irregular surfaces. 3 guide chamfers guarantee a stable exit from the hole and an exact roundness of the hole.

Note:

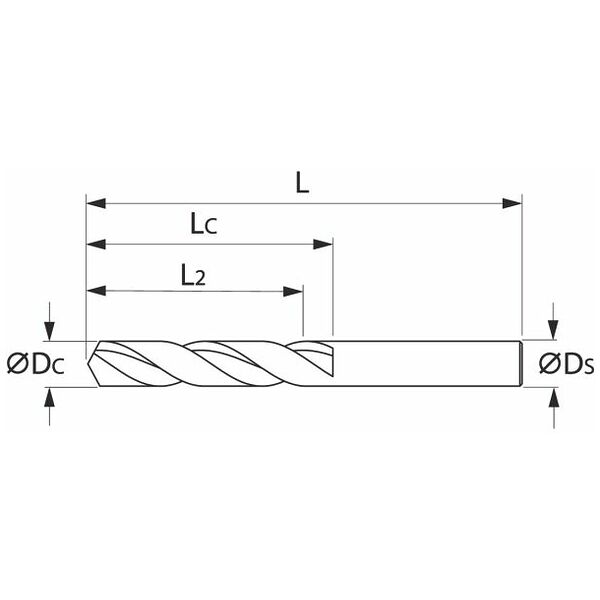

Flute length LC = L2 + 1.5 × DC.