Version:

Surface grinding and external cylindrical grinding wheels,

highly developed, with

super-abrasives (CBN or diamond) in synthetic resin bonding. The high-strength,

vibration-optimised VIB STAR grinding wheel base body permits a

high damping for a smooth, even grinding process with high surface quality.

- Extreme performance improvement (G-factor) compared to conventional grinding media.

- The vibration-damping design of the carrier body significantly increases the working life.

- Continuous self-sharpening effect due to even power consumption and avoidance of cyclical sharpening operations.

Diamond coating for high performance grinding of

short chipping non-ferrous materials such as carbide, ceramic materials (PCS), hard coatings.

Application:

- General use for all materials from a hardness of about 58 HRC (limit of economic use).

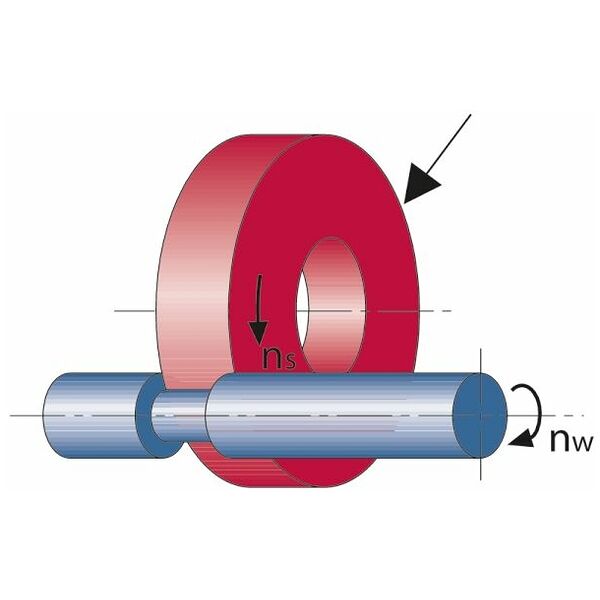

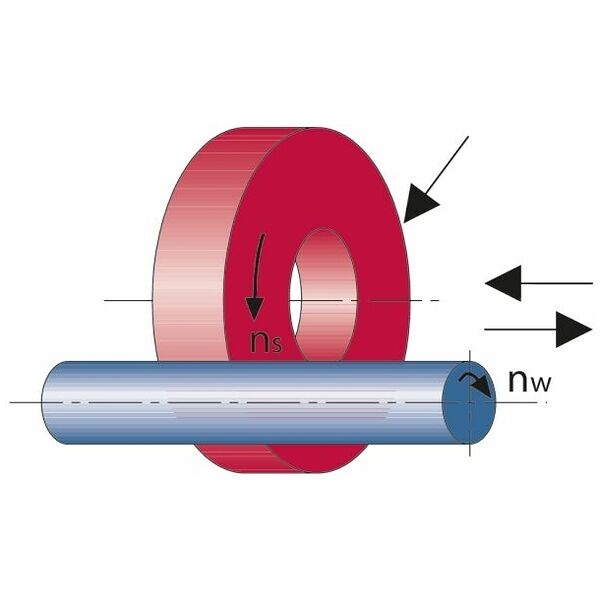

- For surface grinding and external cylindrical grinding (straight longitudinal grinding, recess grinding).

- Can be used on all commercially available grinding machines for tool and die making and machine tool building, e.g. Jung, ABA, Blohm, Elb, Mägerle, Ziersch & Hotz, Jones & Shipman.

- Cooling with emulsion or grinding oil is necessary.

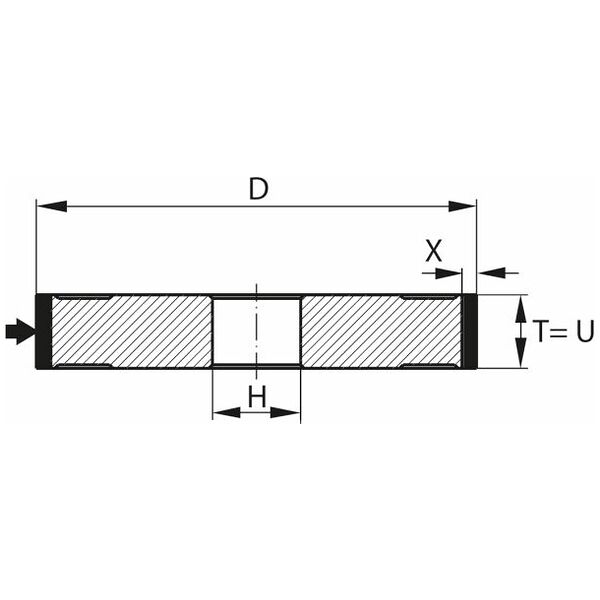

- Superabrasive CBN / diamond grinding wheels are always used with less than half the wheel width compared to that for conventional grinding wheels.

Specification:

D126C75B-VIB-STAR W-Carbide.

Note:

These grinding wheels can be dressed on a steel block at an infeed of approx. 0.02 mm. Alternatively with a dressing tool No.

599600. Sharpen grinding wheels (opening up the bonding) using sharpening stone No.

599840.