GARANT premium sawing system

The complete range for cost-effective production.

The GARANT premium sawing system for outstanding precision:

Highly flexible for highest precision.

Complete range for cost-effective production.

The sawing system and the option of clamping without screws or similar protruding, makes flush cutting off of workpieces possible.

Sawing with outstanding precision

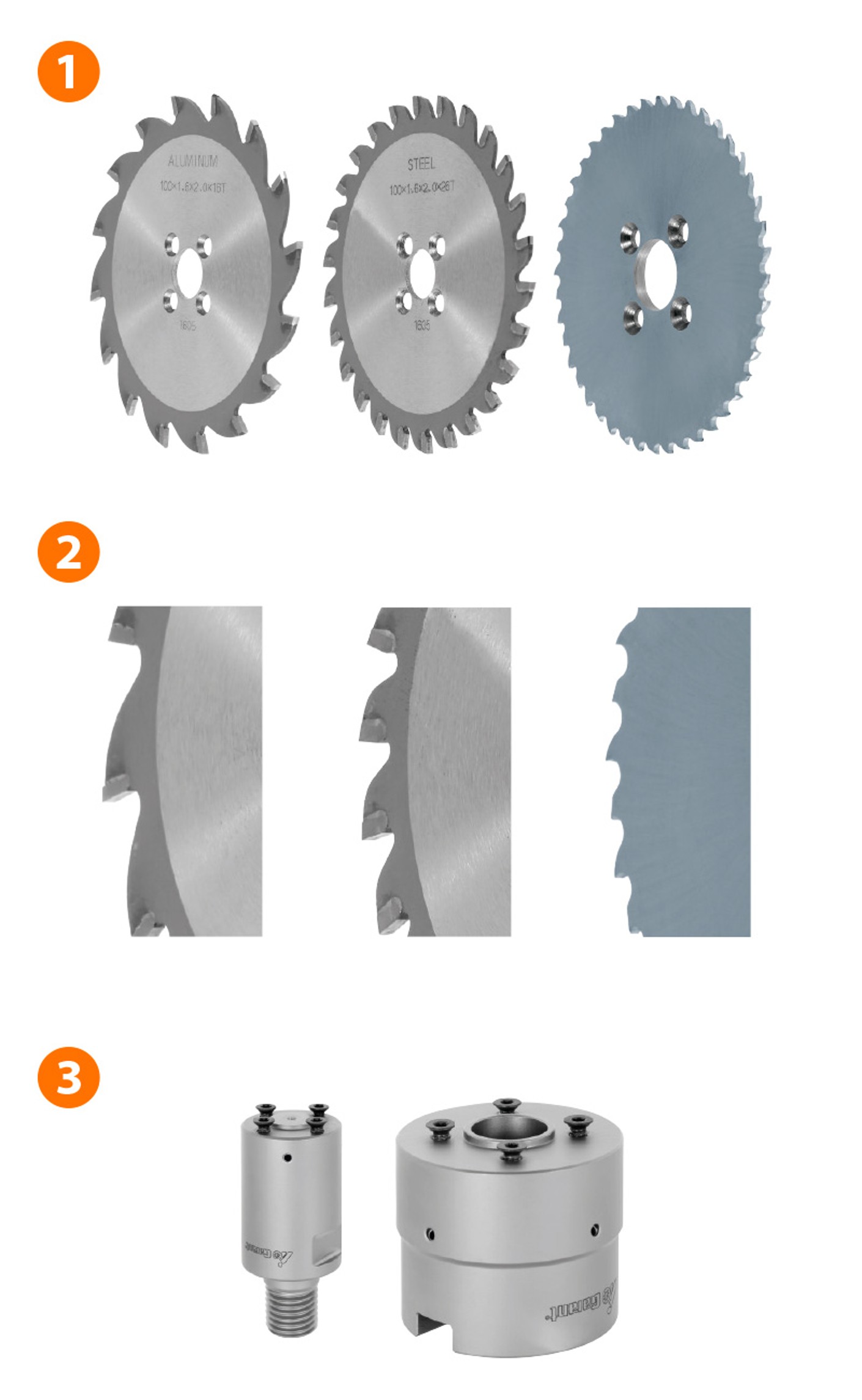

1. Specialists and multi-talent:

Select the right saw blade for aluminium, steel or general purpose applications.

2. High efficiency:

Use the diverse solutions available for your production: a large selection of tool materials, diameters, cutting widths and numbers of teeth ensure cost-effective machining.

3. Sawing with a system:

Only 4 adapters to cover the entire range of diameters from 40 - 160 mm.

Well thought-through, down to the last detail:

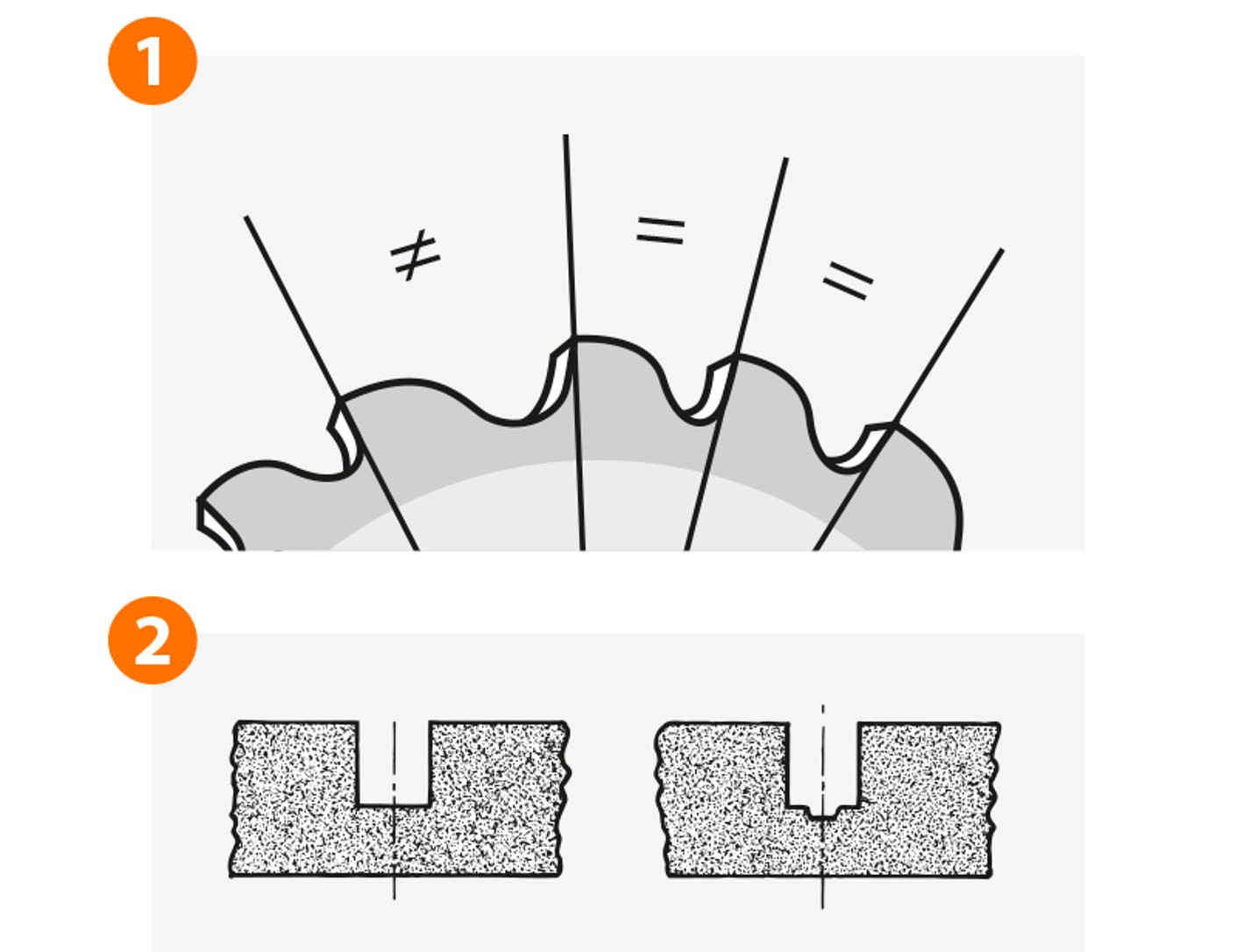

- The unequal spacing of the saw blade ensures a smoother machining process.

An optimised coating makes the solid carbide saw blade the ideal tool for a wide variety of materials.

Due to their collar, solid carbide circular saw blades are always stable, even for narrow saw cuts. - The chip transport is optimised by the adapter with oblique cooling channels - this increases the process capability and improves surface quality.

The teeth share the creation of the machined kerf by an alternating offset tooth profile. This means a smooth bottom to the cut slot is achieved.

Running the saw in:

Since initially the saw blade is still very sharp, careful running in of the saw blade will increase its working life. For this it is best to run at 80 % of the cutting speed and of the feed rate.

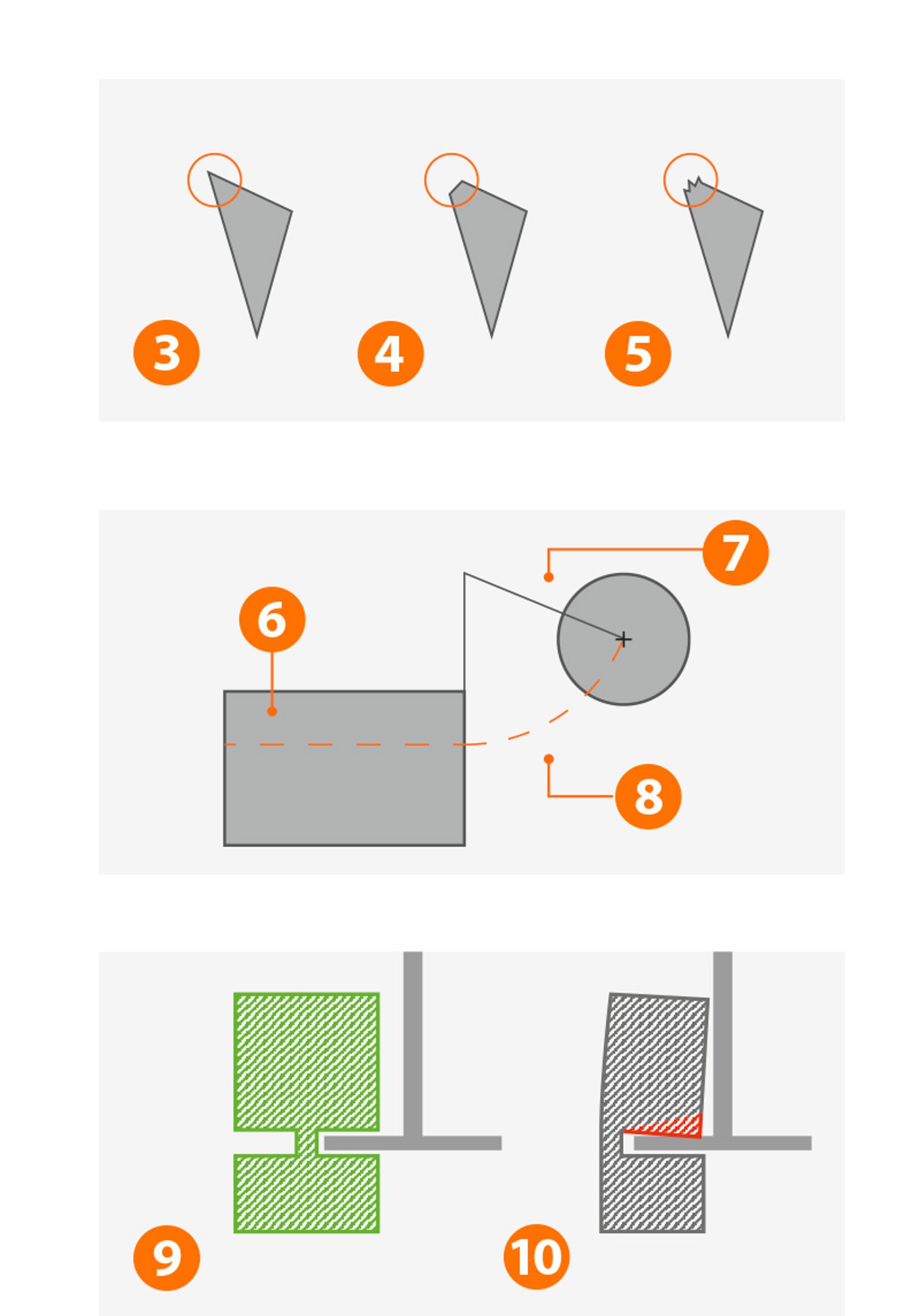

3. New: Sharp cutting edge

4. Run in: Even chamfering of the cutting edge

5. Without running in: Uneven break-offs from the cutting edge.

Approach (6.-8.):

We recommend whenever possible that the saw blade should approach the workpiece along a radius. This reduces both vibration and also the risk of rapid wearing of the tool. If it is not possible to approach the workpiece along a radius, reduce the feed rate until the saw blade is fully engaged in the material.

Parting off (9.-10.):

When parting off, always work from both sides of the workpiece. If the workpiece is parted from only one side, there is a greater risk that the workpiece will sag on to the saw blade thus causing damage to both the workpiece and the saw blade.

Other tips:

- We recommend an emulsion of > 8 %, especially when machining stainless steel.

- In the event of vibration we recommend reducing the cutting speed as the first measure to overcome the problem.

- Especially when using screw-on adapters, keep the overhang as short as possible.

Product video sawing

The GARANT premium sawing system has no projecting screws or similar, therefore it can perform flush cutting off of the workpiece. The advantages of the sawing system are obvious:

- More teeth than parting-off milling cutter with inserts, for shorter process times.

- Thinner saw cuts can be achieved – thus less loss of material.

- Lower cutting forces, thanks to the interaction of the sharp cutting edges, the narrow cutting kerf and the distribution of the cutting task across more teeth.

The GARANT premium saw system is thus suitable even for machines with lower drive powers, and delivers high precision.