Head protection – Ideally protected with safety helmets

Protect the vulnerable head region from danger

The head is one of the most vulnerable parts of the human body. Different external physical influences can not only damage the skin and bones, but also the brain in particular with its vital functions. In order to protect against these influences, humans invented head coverings centuries ago. Specialist safety helmets and thus the industrial safety helmet as we now know it came into use only during the industrial age. In the modern working environment, safety helmets are essential in various different hazard areas. These areas can be split into five categories:

- Physical: falling objects, suspended loads, impacts

- Chemical: splashes of chemical liquids

- Thermal: molten metal splashes, heat, thermal radiation, hot liquids, weather conditions

- Visual: UV radiation

- Electrical: electric arcs

In order to prevent accidents at work, protecting against these dangers is very important.

Different types of head and face protection

Safety helmets

Helmets come in three different shell shapes: straight (1), straight with rain gutter (2) and with pulled-down neck and rain gutter (3). Industrial safety helmets consist of thermoplastic or thermoset, each with their own different properties and fields of use in construction, industry, hot operations and electrical engineering. More detailed information on this can be found on the type plate, amongst other places. Special shapes in this category are scaffolder’s helmets and safety helmets for forestry.

The different shell shapes at a glance:

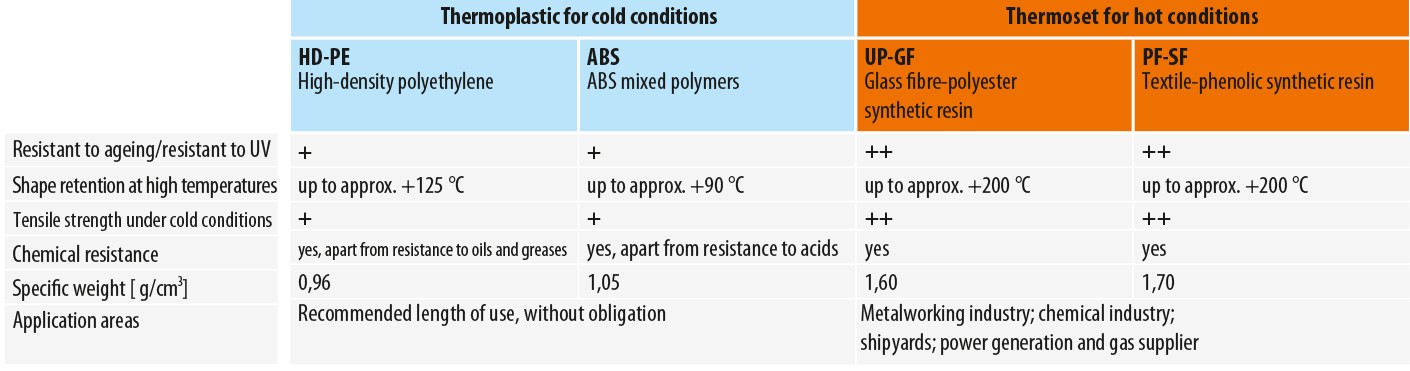

Material types of industrial safety helmets:

Marking:

- Abbreviation “CE”

- 4-digit identification number of the registration point

- Manufacturer’s ID

- Year and quarter of manufacturer

- Manufacturer’s type designation

- Standard applied

- Helmet material used

- Size or size range in cm

- Other markings as per DIN EN 397:

- LD (Lateral Deformation) hazard due to lateral forces

- MM (Molten Metal) hazard due to spatter of molten metal

- 440 V AC hazard due to brief unintentional contact with voltages up to 440 V

- + 150 °C use at very high temperatures

- − 20 °C or − 30 °C use at very low temperatures

Face protection

Face protection is especially important if fast flying particles, metal splashes, chemicals or electric arcs occur during work. It consists of a transparent protective visor which can be attached directly to a helmet or a head attachment.

Impact caps

In terms of their shape, impact caps are based on baseball caps. Due to their plastic insert, they offer light head protection, such as against stationary sharp-edged objects. They must not be used as a substitute for industrial safety helmets.

Welder’s masks

Welding poses hazards, which include very high temperatures, against which employee must protect themselves. A welder’s mask protects the entire head and the face against radiation, heat and sparks. Due to the installed field of view with welding filter, the employee can see his/her workstation. The highly modern welder’s automatic masks also boast several shade levels, which facilitate different kinds of welding work. Caps or hoods made from flame-retardant cotton can be worn underneath the mask.

Accessories

The individual components of head and face protection must be regularly replaced, either due to hygiene or because they are damaged. Others are necessary to supplement features. Accessories include, for example:

- Sweat bands, chinstraps and neck protection for safety helmets

- Adapters for connecting protective visors

- Front covers and welding filters for welder’s masks

Do you have any questions? Our experts are keen to help you at any time:

Selection criteria for head and face protection

Safety

Depending on the activity and influence factors, different products are eligible for head and face protection. The most important selection criterion here is the safety aspect. Safety helmets for construction must meet different requirements than safety helmets for industry, hot operations or electrical engineering.

This is why helmets made from thermoplastic are used in the construction industry, in assembly, in mechanical workshops and the food industry. This can be a high-density polyethylene (HD-PE) or ABS mixed polymers.

By contrast, head protection in the metal-working industry, the chemicals industry, in shipyards as well as power generation and gas suppliers consists of thermoset; for example, a glass fibre-polyester synthetic resin or a textile-phenolic synthetic resin. These are materials are especially ageing-resistant, shape-retaining up to approx. +200°C and break-proof in the cold. Furthermore, they protect the wearer from liquid metal splashes right through to lateral distortion and are unresponsive to chemicals. Helmets for electricians also protect against electric arcs.

Wearing comfort and wear duration

As with each element of personal protective equipment, head and face protection can be a strain on employees, such as due to the additional weight or the restricted field of vision. That is why wearing comfort plays such a key role in selecting the right product. In industrial safety helmets, the straps of the interior padding (1) should be produced from textile and a sweat band (2) should be present, for example. Furthermore, only head protection should be chosen which enables tailored adjustment (3) (§2 of the PPE usage Regulation). For industrial safety helmets, precision adjustment to the circumference of the wearer’s head takes place during fine adjustment.

Safety helmet for welding work

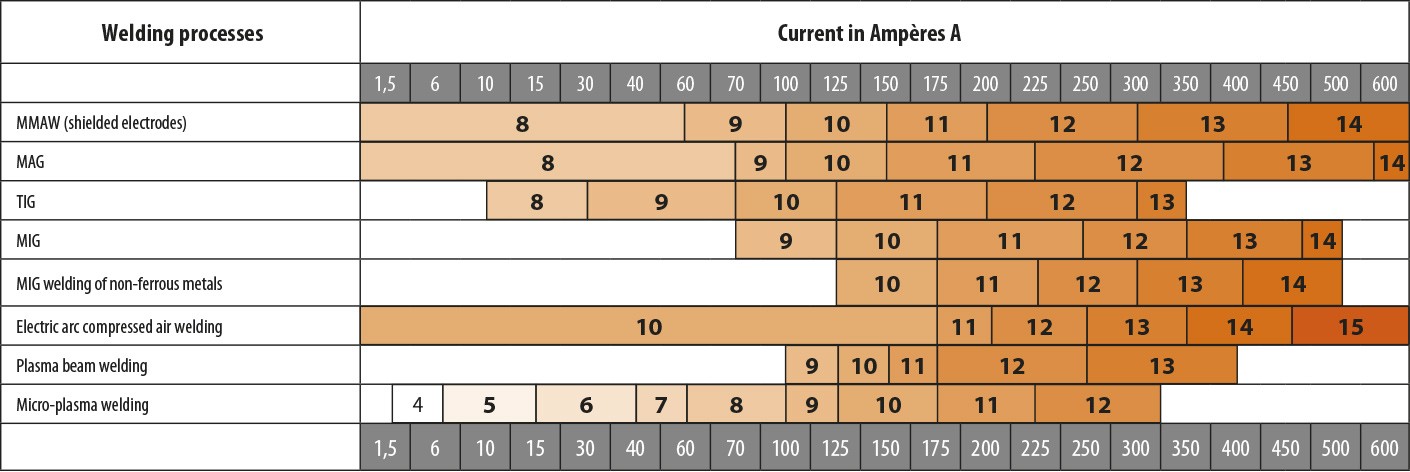

Visual radiation hazardous to the eyes is generated during welding and cutting work. This can cause burns to the retina or damage to the cornea. For this reason, it is essential to wear adequate protective equipment which provides the correct level of protection. The protection levels of the welding filter are based on the chosen welding method and the associated current. For example, up to nine shade levels are recommended for micro-plasma welding (levels 4–12), whereas there are five for plasma beam welding (levels 9–13).

This table recommends the best shade levels of the welding filter for various different welding processes. Depending on the application conditions, the next higher or lower level can be used:

Comprehensive product selection and advice regarding head protection

Compiling the personal protective equipment for all the staff at your company can be a complex matter. Personal support is offered by our PPE specialists: We advise you personally and support you professionally with your risk analysis, product selection, wearing tests and training sessions for your employees. Our experts are the best to ask about the protective effects of the individual PPE products, can advise on statutory regulations and can provide you with a summary of the market.

In our product range, you will find pre-selected head and face protection from reliable manufacturers. Just like with the tools, here we abide by our mantra: quality-driven since 1919. We are able to supply high-quality safety helmets , protective face screens , impact caps , welder’s head protection sowie passendes Zubehör.

Important legal regulations

Various European standards define which properties must be demonstrated by the various head and face protection gear. These include:

- EN 50365: Electrically insulated helmet for working on low-voltage systems

- EN 168: - Non-optical test methods

- EN 166: Visor / clear view glass

The following standards in particular apply to head and face protection for welding work:

- EN 169 on filters for welding work

- EN 175 for welder’s masks

- EN 379 on automatic welding filters

Frequent questions on head protection

Are there special industrial safety helmets for people who often suffer from headaches?

There are no special safety helmets for people who suffer from headaches. In order to reduce the risk of headaches, choosing a safety helmet that is highly suitable from an ergonomic perspective is recommended. In this regard, a decent fit (head size), low weight and easily adjustable interior fittings play a key role. The adjustment mechanism with rotary ratchet has an advantage over a snap-lock in that the interior fittings can be steplessly adjusted to the circumference of the wearer’s head.

Can industrial safety helmets be colour coded, repainted or have stickers affixed to them?

This is not possible, because the helmet material can become damaged from paint, solvents, adhesives or self-adhesive labels, thus impairing the protective function of the helmet. Exceptions only apply on the explicit instructions of manufacturers.

What service life do safety helmets have?

This essentially depends on two factors: the condition and age of the head protection. If defects and damage are visible on the safety helmet or if there was a heavy impact, then this product should be replaced in order to ensure employees' safety at work.

Due to the influence of various factors, the protective function of the helmet also reduces over time. Such factors include, for example, climatic effects, UV radiation and air pollution. Industrial safety helmets made from thermoplastic should be replaced after four years of use. Helmet shells made from thermoset can be used reliably for up to eight years.

Do you have any questions? Our experts are keen to help you at any time:

The Hoffmann Group provides you with everything from a single source:

- We provide you with tailored advice

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Do you have any questions? Our experts are keen to help you at any time:

The Hoffmann Group provides you with everything from a single source:

- We provide you with tailored advice

- Risk analysis, help with product selection, wearing tests, training sessions and special service offers (glove plans, skin protection plans)

Personal protective equipment also includes: eye protection, breating protection, hearing protection, foot protection, hand protection, protective work wear, work clothing, fall protection and skin protection. This takes you to the overview.

Contact us now

Contact us now