GARANT Xtric centring vice

Centre clamping has never been so easy

Save valuable time with the GARANT Xtric centring vice

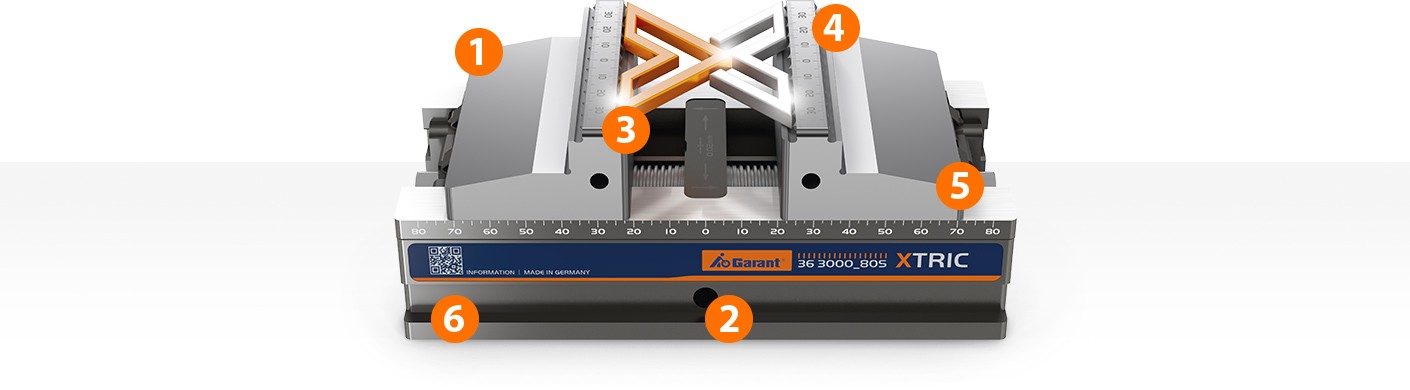

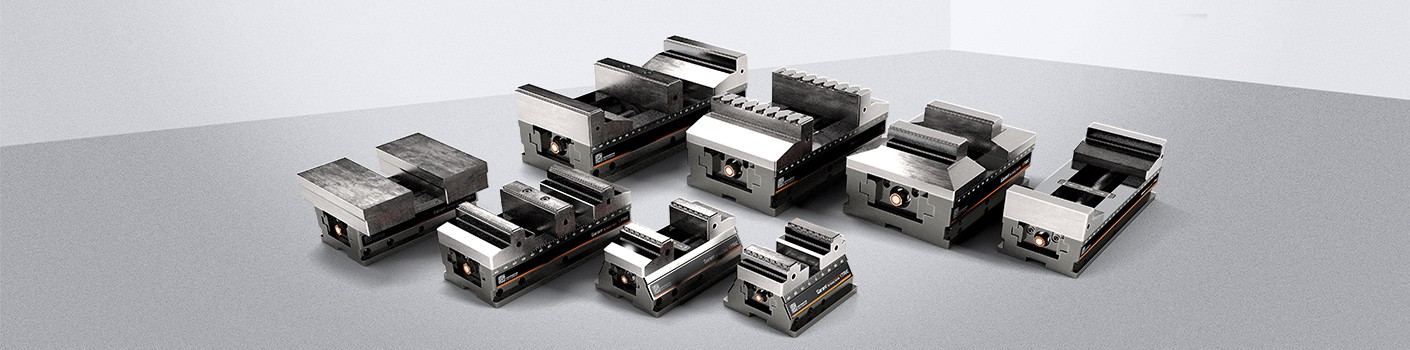

The revolutionary centric vice GARANT Xtric is multi-functional and is particularly easy to use. The unique clamping concept with quick-change system for the jaws saves you a lot of time when clamping blank parts and finished parts. The versatile attachment options offer great scope for flexible handling. All this combined with very high precision and quality – Made in Germany.

It´s not a trick. It´s an XTRIC.

Discover the advantages

1. XPRESS

Jaw change within 8 seconds due to click mechanism.

Quick and easy: First insert the top jaw into the dovetail and press it down with the spring plates. This is how easy it is to change the clamping range or exchange the jaws. A clamping distance between 0-144 mm can be achieved.

2. XCELLENT CENTRIC

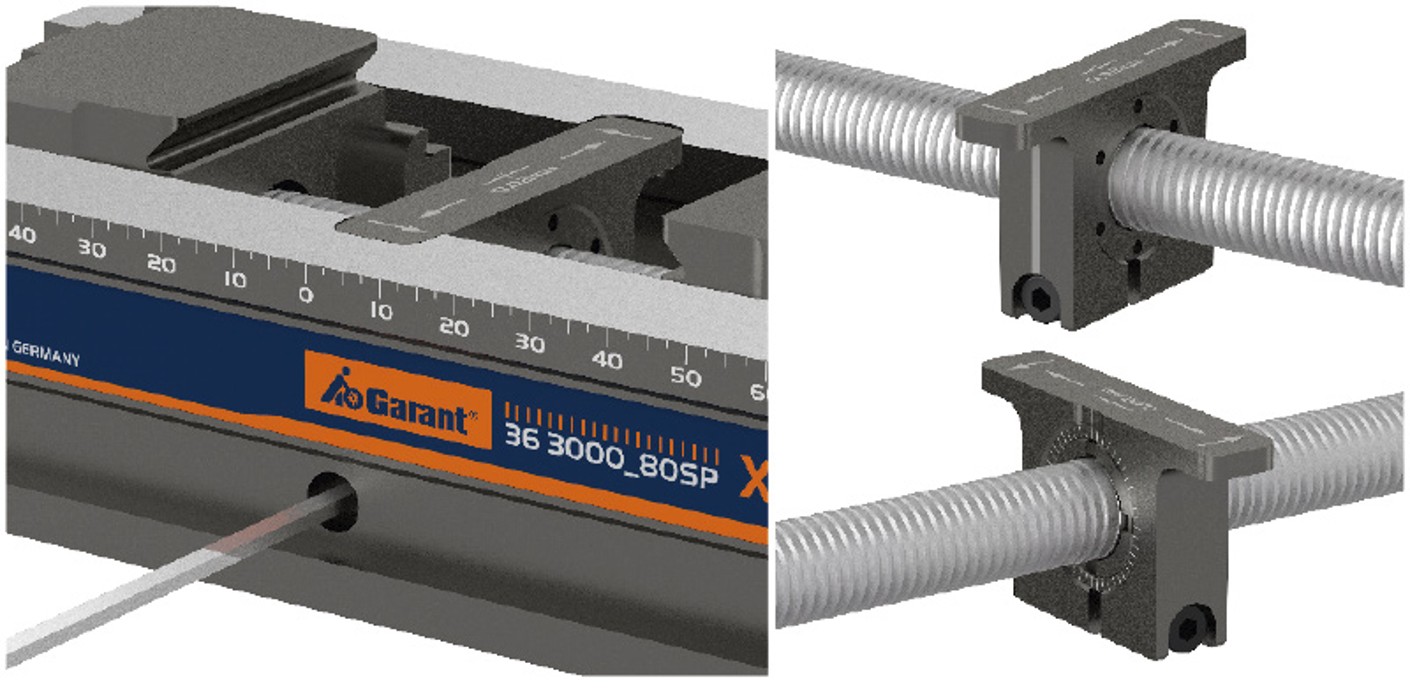

Adjustment of the clamping centre in the μ range

When clamping a workpiece using multiple XTRIC vices, the centre itself can be adjusted to suit the production requirements with a few movements of the hand. Adjustment 5/10 mm each side (1 mm in total) by means of scale graduations on the spindle bearing. After the screw has been released, the centre can be adjusted using a pin wrench. After this the screw is retightened.

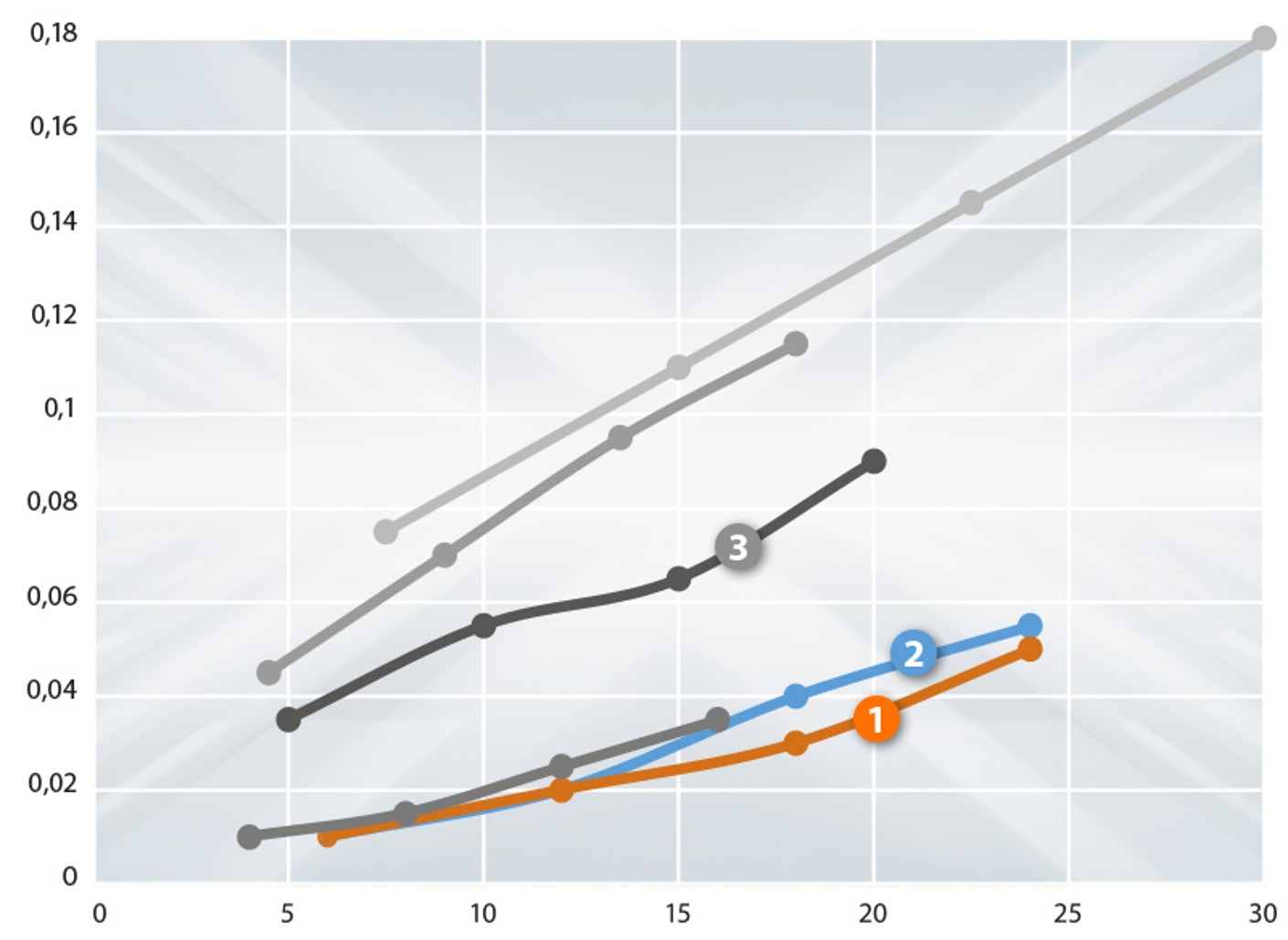

3. XACTLY PRECISE

Better clamping accuracy compared to the competition (3)

For clamping, the jaw is pushed along the specially shaped dovetail in the guide track, thus producing a pull-down effect. This creates minimal jaw lift-off whilst achieving very high clamping accuracy.

(1) Version with pivoting jaw

(2) Version with fixed jaw

(3) Competition (grey)

4. XTRA STRONG

Linear clamping process up to 25 kN clamping force

The special GARANT tooth form of the gripper jaws makes pre-indentation at maximum clamping force unnecessary. Ideal for clamping blank parts, because the 25kN can be applied directly to the component. Unlike for other manufacturers, the stated clamping force is not „made to look better“ using the arithmetical sum.

5. XTREMELY VARIABLE

Various set-up options

The Xtric can be used with clamping claws, via direct adaption on the "LANG" system, or with adapters on all zero-point clamping systems.

6. XTREMELY FLEXIBLE

Pivoting function

The pivoting jaw automatically adapts to the face of the workpiece, and can also be used without problems for finished parts. Suitable for every clamping situation!

Our customers are convinced of the GARANT Xtric

“The accuracy and the flexible quick-change system for the jaws to vary the clamping range in seconds impressed us.”

Philipp Ramerseder, Managing Director APM Maschinenbau GmbH, Perlesreut/Prombach

“The GARANT XTRIC offers an unbeatable price-performance ratio which we have never previously encountered. New features such as the changing of jaws have absolutely convinced us.”

Christian Knödlseder, Managing Director Kühberger Metalltechnik GmbH, Waldkirchen

The GARANT Xtric is also suitable for automation projects.

The video shows it in use with an articulated robot at company idee-werk GmbH.

Matching assembly set-up station

For mounting and removing workpieces in the clamping device andfor changing or turning the clamping jaws.

The assembly station can be fitted to the workbench by means of two screws. Clamping studs e.g. No. 363190

can be used to position the clamping device or jig with pitch 52/96 to the assembly station and can be locked and unlocked by means of the side bridge. Set-up times are optimised with high process reliability when clamping workpieces orchanging clamping jaws. Suitable for clamping devices with pitch 52/96, e.g. GARANT Xtric

.

Advantages:

- Locking and unlocking without tools

- Reduction in set-up times

- Ensuring safety at work

View GARANT Xtric in the eShop

View GARANT Xtric in the eShop

To the operating manual (PDF)

To the operating manual (PDF)