GARANT Zero Clamp

Clamping summed up.

Even on tomorrow's complex jobs - precise and reliable clamping.

The growing complexity of production and the increasing diversity of components pose new challenges for the production process.

Garant ZeroClamp scores highly thanks to its simple design, high flexibility and unlimited range of applications. Thermal expansion is compensated by acting always in relation to the centre axis, so you need only one type of clamping stud. This offers you a great degree of freedom when arranging the clamping points, and also simplifies handling at all stages of production.

GARANT ZeroClamp is the best way of setting up for production.

As Europe’s leading system partner for quality tools, the Hoffmann Group offers you reliability, stability, advice and on-site service.

PRODUCT VIDEO

GARANT ZeroClamp zero-point clamping system

Garant ZeroClamp scores highly thanks to its simple design, high flexibility and unlimited range of applications. Thermal expansion is compensated by acting always in relation to the centre axis, so you need only one type of clamping stud. This offers you a great degree of freedom when arranging the clamping points, and also simplifies handling at all stages of production.

.

Advantages

Increase of efficiency

Efficient and precise clamping with greater variability thanks to the innovative GARANT zero point clamping system.

Time saving

Up to 90% time saving due to lower set-up, changeover and non-productive times.

Increased productivity

Up to 70 % more productivity in your manufacturing process.

Cost savings

Saving the alternative costs of a new purchase due to optimised usage of the machines.

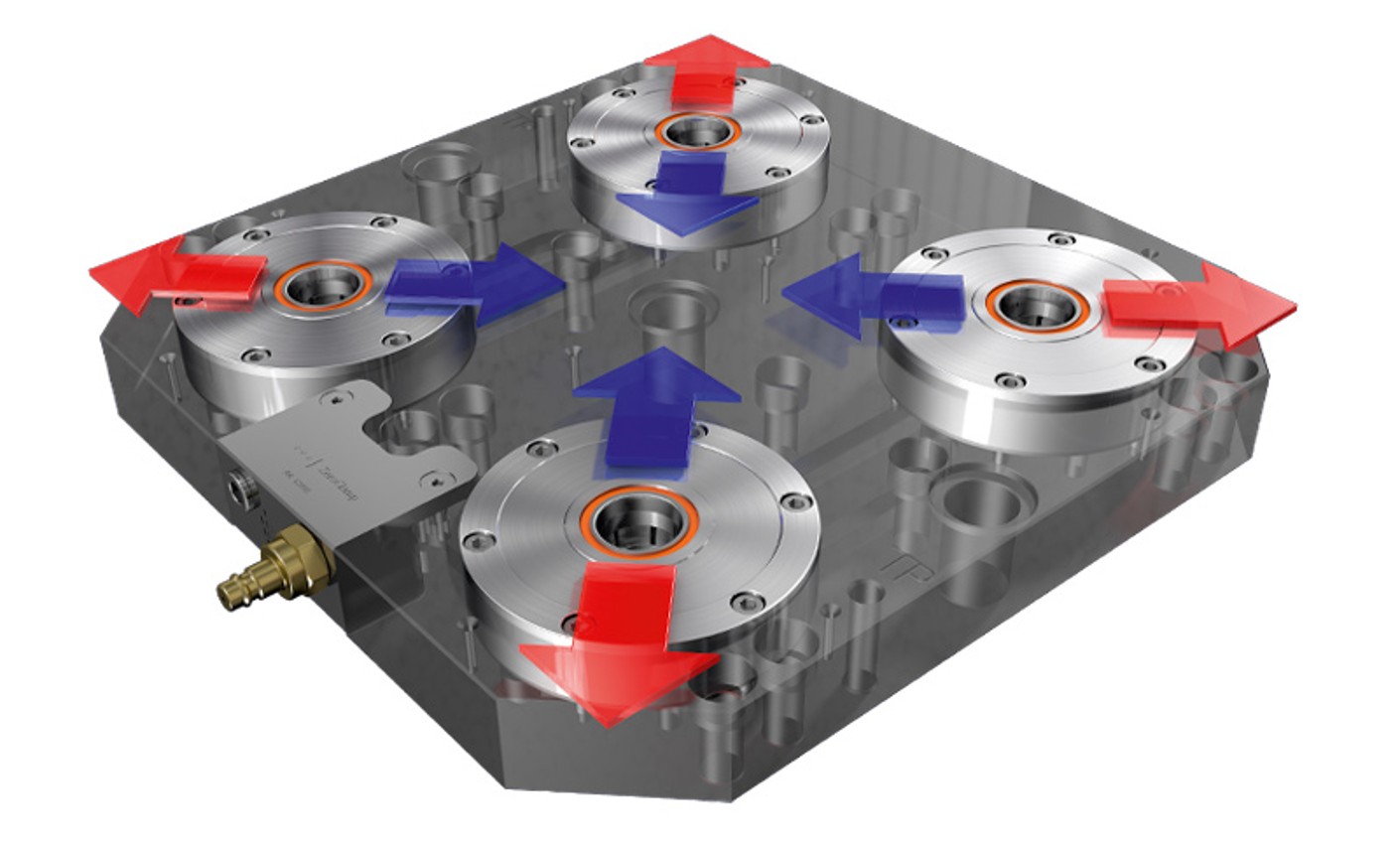

Thermal symmetry - always in relation to the centre

Conventional technologies use floating studs to compensate for thermal expansion – this produces particularly inaccurate results if workpieces are rotated around the central axis. Due to the central zero point, GARANT ZeroClamp provides absolute thermal symmetry at all times! - The absolute zero point: Compensation for thermal expansion is always symmetrical about the central axis. - Special zero-play clamping cones for low-vibration operation. - No sword studs, no floating studs.

Simply brilliant.

Only 5.5 bar compressed air is necessary to release the clamping studs – locking is by spring pressure.

- 25 kN clamping force with clamping pot ∅ 120 mm (40 kN at ∅ 138 mm), not self-locking.

- Low-maintenance, sealed system without hydraulic oil: no leakage, resistant to swarf.

- Process reliability thanks to easy application.

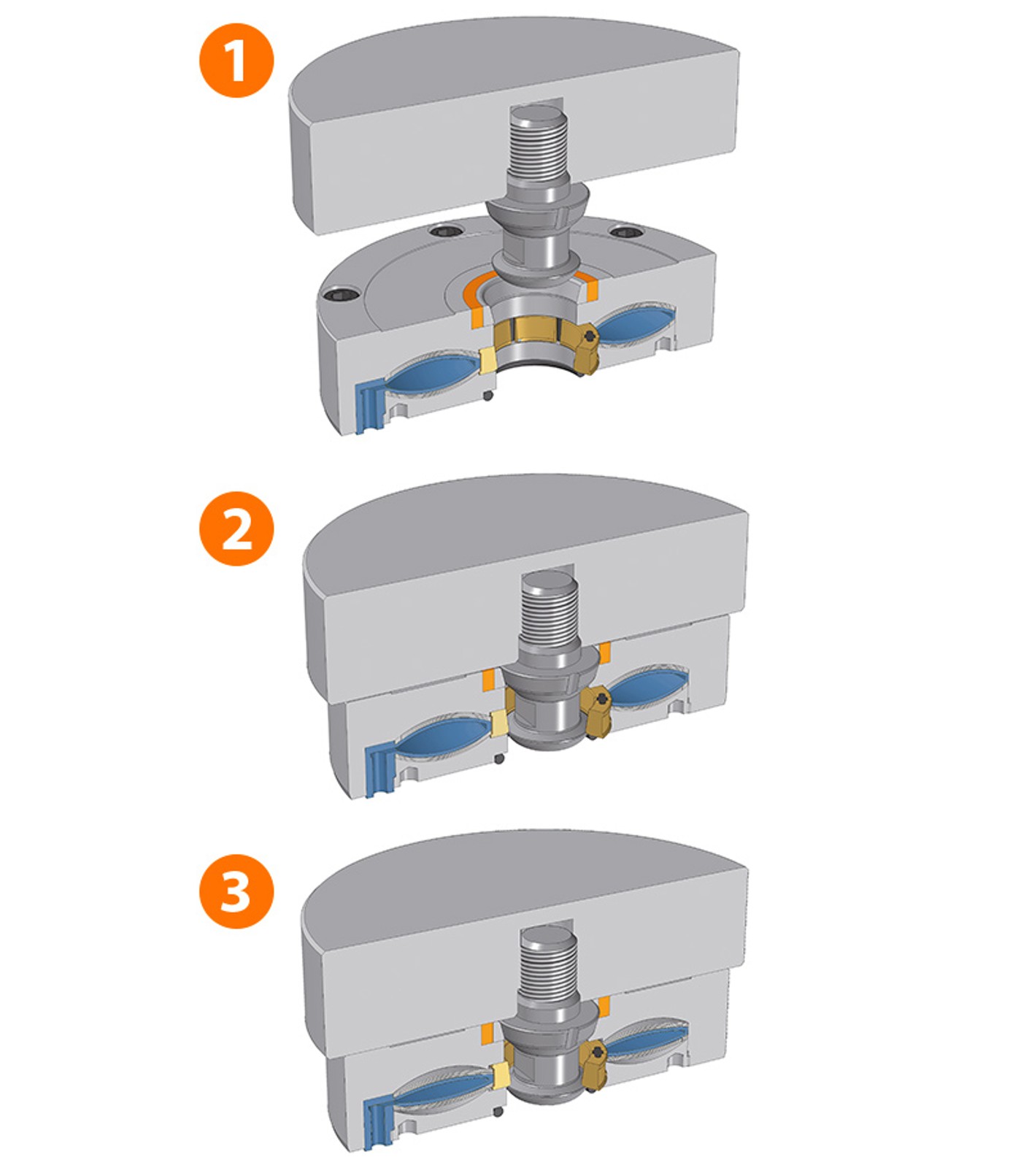

Operating principle in cross-section:

- The pallet is simply placed on the open GARANT ZeroClamp clamping pot. Therefore there is no risk of jamming.

- The spring elements keep the locking unit (clamping wedges) open due to the air pressure (5.5 bar) in the air hose.

- When the pressure in the air hose is released GARANT ZeroClamp positions the workpiece on the flat face with a clamping force of 25 kN (∅ 120 mm) and 2.5 μm repetition accuracy.

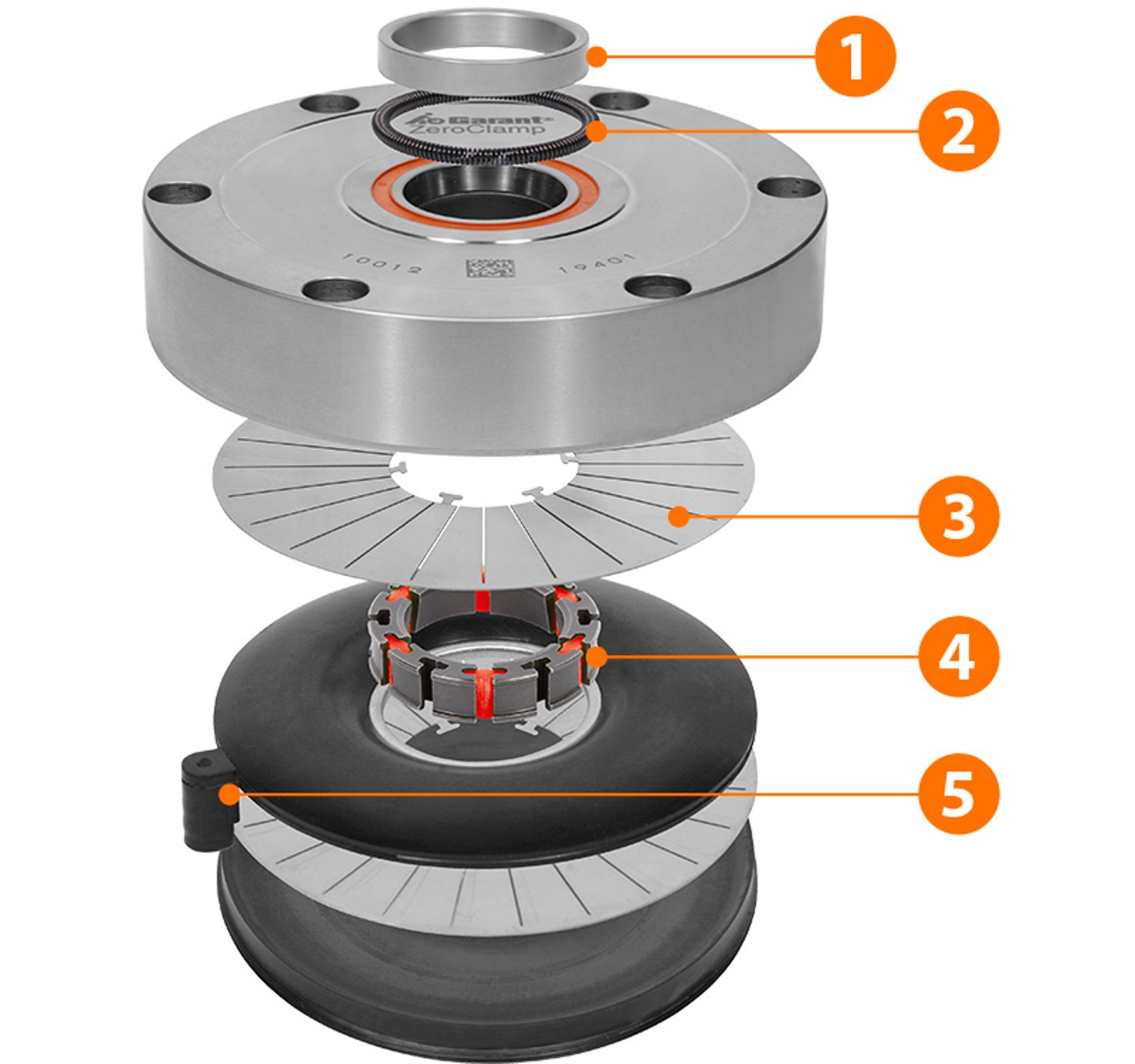

Design

Only 8 parts for reliable clamping force.

- Centric clamping, free of backlash within the hardened steel taper

- Radial spring supported by Viton, high resistance against cooling lubricants

- Non-wearing technology, an air hose and clamping plates provide the required clamping force

- Locking unit

- Air connection for release

CUSTOMER OPINION

Constant clamping

Now in use for over eight years, the verdict is more than positive: the time saved when milling due to the reduced setup times amounts to 50% or more depending on the process, which in turn has resulted in an increase in productivity. And if the component needs machining again after the measurement process, the ZeroClamp makes positioning quick, precise and capable of repetition accuracy. The repetition accuracy of less than 2 μm is a major advantage. “It has more than proved itself within our operations. As well as the high levels of process reliability and employee satisfaction, the cost savings achieved also indicate we should expand the system further,” explains Urlberger. “Based on the reasons given, we would recommend ZeroClamp every time,” he says in conclusion.