Horizontal setting device for setting measuring tools

GARANT SB1 setting bench – easy and convenient operation for the best results

The GARANT Setting Bench SB1 is a horizontal setting device with top precision. It allows quick and convenient setting of various measurement tools in the measurement ranges of 300 mm, 600 mm and 1000 mm. The robust setting bench is designed for daily use in manufacturing, production and the workshop.

Benefits of the GARANT SB1 setting bench

- Top precision: precise up to the nearest micrometer

- Fast: settings can be made in a few seconds

- Digital: adjustment data is stored and can be retrieved and reproduced at any time

- Simple: enter the value and the movable slide positions itself automatically

- Suitable for workshop use: robust design, touchscreen with large control panel

Suitable for setting internal and external measuring tools, such as:

- Vernier calipers

- Universal measuring instruments

- External micrometers

- Internal quick calipers

- Internal precision bore gauges

Get an overview of the functions and benefits of the GARANT Setting Bench SB1 in the video.

All features at a glance

Simple and convenient to use.

The device is high quality and has a solid granite base and high-precision guides. The highly accurate motor control regulates the set values in real time, even with a variety of gauging forces.

- Large intuitive operating display: touchscreen, input of internal and external sizes.

- Integrated tolerance calculator: calculation of the tolerance from the nominal size and fit. Direct access to the MIN / MAX / MIDPOINT values that are determined.

- Creating favourites: the history is recorded and can be accessed at any time. Saving of favourites for repeated setting of measuring tools.

- Connections: Internet connection, USB ports for scanners and label printers.

- Optional adapters for setting different types of measuring devices

- Solid granite base

- Adjustable gauge blocks for internal and external measurement

Availability of adjustment data

After the printed label has been applied to the measurement tool, the setting data of the tool can always be traced and, by scanning in, can be restored using the setting bench.

- Adjust the measuring device

- Print the label

- Apply a label to the adjusted measuring tool

- Scan the label

- The setting value is recorded

Guaranteed economic effiency

The conventional setting method takes an average of about 90 seconds. Four steps are necessary:

- Look for gauge blocks

- Add the values

- Assemble the gauge blocks

- Set the measuring instrument

The average of 90 seconds can easily be exceeded, as the gauge blocks might be missing and there is likelihood of a miscalculation or dust having accumulated on the gauge blocks. Use of the GARANT SB1 setting bench eliminates these potential problems whilst also reducing the time required for the work.

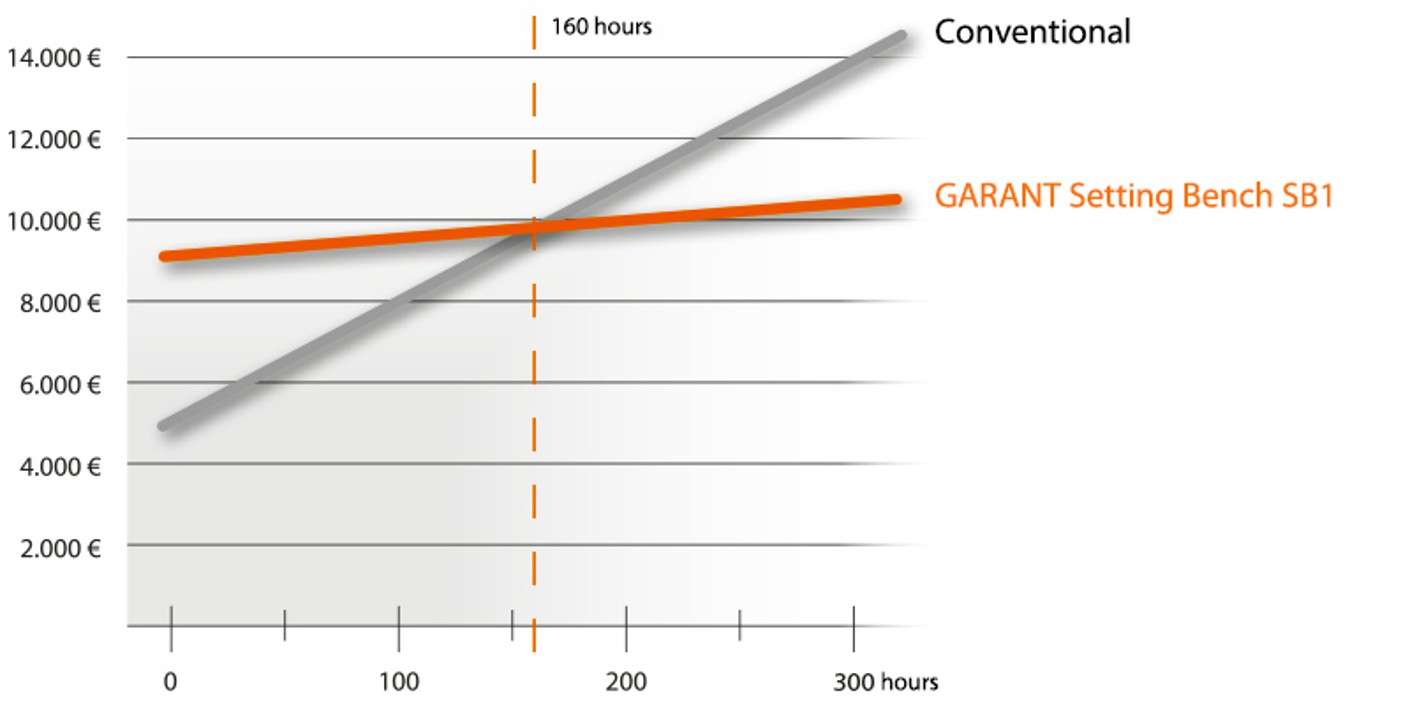

Quickly pays for itself due to enormous time savings.

By comparison with conventional methods, the new GARANT SB1 setting bench has already paid for itself after only about 6,400 measurements. The time saving compared to the conventional setting method is approx. 85%.

Additional information

You can find the GARANT SB1 setting bench in our e-shop:

You can find the suitable SB1 adapters for your measuring tools here:

You can find additional information on the setting device in the brochure:

Do you have any questions?

Contact us!

Our expert specialist advisers will provide you with individual consultation concerning the GARANT setting bench.

To the brochure

To the brochure To consulting

To consulting