How to Get Precise Boring Results

FINE BORING HEADS FOR PRECISE RESULTS

Boring tends to be a niche in machining, although boring tools are very diverse and allow for very precise results. Our fits for diameters from 0.3 mm to more than 420 mm with accuracy down to µm level speak for themselves.

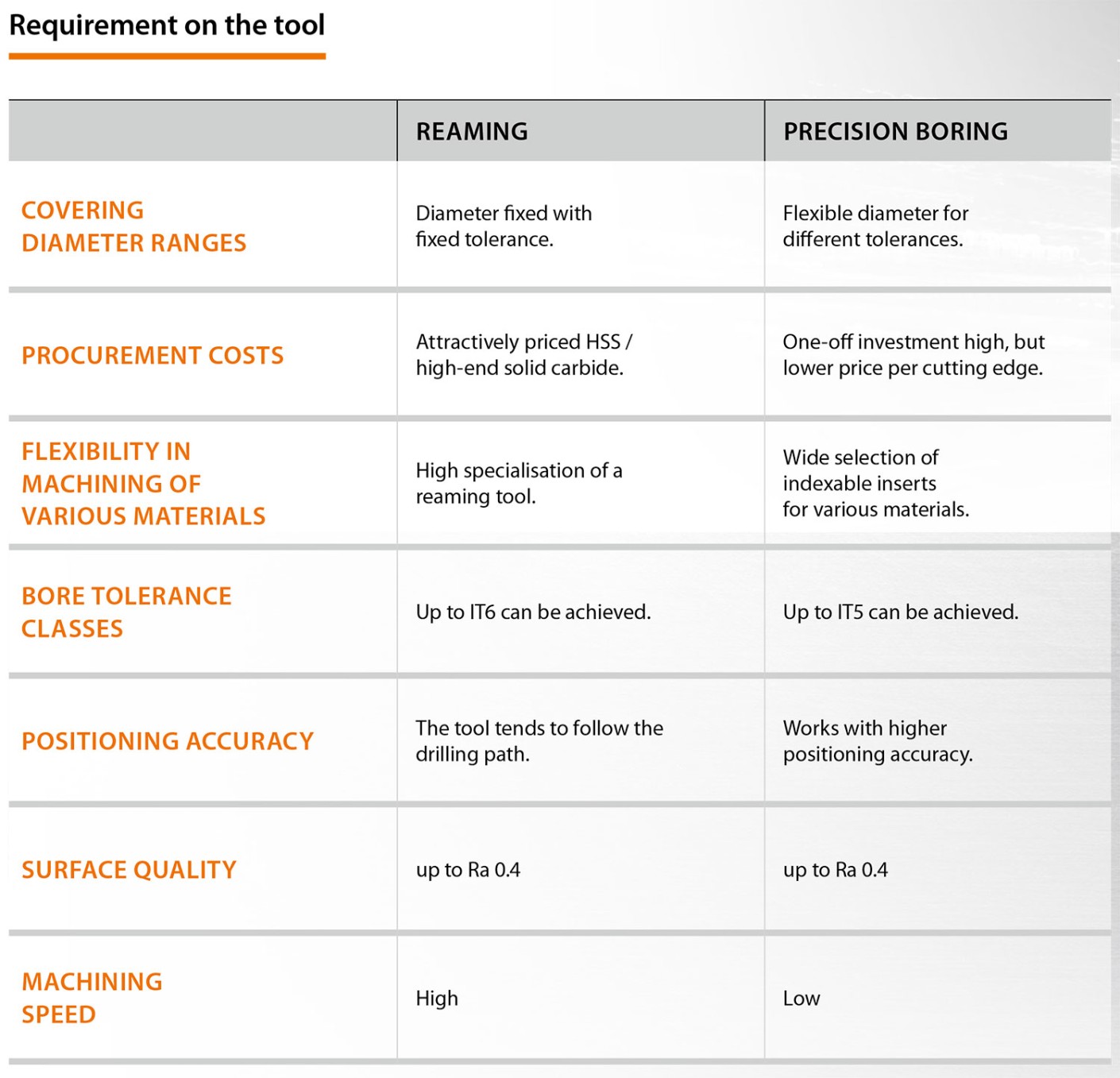

You may think that reaming is better. Please see the chart to the side providing a brief comparison of the two.

Conclusion:

Boring is a must-have in every production facility.

We can offer you a wide range of GARANT boring systems that are suitable for your machines and requirements – or alternatively just ask your personal Hoffmann Group contact person.

7 SMALL STEPS TO HIGH PRECISION BORING

Boring is often used when a hole needs to be precisely finished – in particular for intermediate sizes and tolerances other than H7. To achieve the desired tolerance, a gauging cut provides the final data.

CONCLUSION:

Maximum precision in terms of the diameter, roundness, positioning, cylindrical form and surface roughness can only be achieved using a precision boring system. We can, of course, also offer you the ideal measurement tools.

FLEXIBLE ON BOTH SIDES: VARIABLE TO THE MACHINE, TAILORED TO THE APPLICATION

The GARANT boring system offers you the variability you need for your production operations – including the main machine connections and boring diameters ranging from 0.3mm to 420mm.

In the breakdown below, we look at the two sides of boring - the workpiece contact point and the machine interface.