GARANT GreenPlus "Simply sustainable and environmentally compatible cleaning and adhesive bonding"

A plus for people and the environment

The climate crisis and other environmental problems have presented us as a society with huge challenges. It is becoming increasingly clear that everything we do affects the planet,

and there is not much time left for us to change course. But in order for us to succeed, lots of different parties need to play their part. That includes us as a company, too.

SUSTAINABILITY IS NOT A TREND, BUT THE CENTRAL ISSUE OF OUR TIMES

The world is changing ever more rapidly, with some changes fundamentally affecting our lives. Things that today are considered the norm, may be challenged tomorrow. Technologies that have been in use for more than 100 years, such as the combustion engine, are on the verge of obsolescence.

Digitalisation is creating opportunities that were barely imaginable just a short time ago.

The demand for closed cycles, better climate protection and conservation of resources means that product design has to meet new requirements and requires the use of completely new technologies.

NEW INDUSTRY TRENDS

For a lot of companies, sustainability and efficiency have become the key pillars of their business strategy. With our hazard-label-free products in the area of cleaning and adhesive bonding, you can optimise your performance while also helping to protect people and the environment.

Our contribution to protecting people and the environment

The GARANT GreenPlus product range will help you on your way to becoming more sustainable. GARANT GreenPlus products conserve resources and are not required to display hazard labels, making them a dependable alternative to the hazardous substances that have been used until now.

For you that means: lower costs, faster working, better working conditions, and fewer time-consuming safety measures. The products also make a significant contribution to protecting people and the environment. Create the workplace of the future!

Fewer protective measures

As the pollutant levels are low, no complex protective measures are required.

Comply with regulations

Avoid possible sanctions, e.g. for exceeding workplace limit values.

No hazardous chemicals

No need to justify yourself to auditors regarding the use of hazardous chemicals.

Protect your employees

Fewer health problems, meaning less downtime

Easy to use

Instruction manuals do not have to be created.

White safety data sheet

No marking with hazard symbols etc.

Safe working

Fewer potential risks (e.g. risk of explosion and fire)

Protect the environment

Fewer pollutants = less environmental pollution.

Save money

Thanks to lower disposal costs.

Simple storage & logistics

No need to store them in hazardous substance cabinets

Our system solution for cleaning and adhesive bonding.

Hazardous substances can be found in many workplaces – whether in solid, liquid or gaseous form. This poses a risk to the health and safety of employees and also puts a strain on the environment. GARANT GreenPlus provides a sophisticated and environmentally friendly alternative to conventional products.

Our system solutions in the area of cleaning and adhesive bonding have been developed for many different areas of application and have special characteristics that help to protect employees and the environment. These include the reduction of hazardous substances, which is particularly important for protecting nature and people’s health. All GARANT GreenPlus products for cleaning and adhesive bonding are not subject to the application of hazard labels in accordance with the CLP Regulation.

Simply the perfect cleaner for your application

Our cleaners are used in many different areas and for a wide variety of industrial component cleaning applications. We make it easy for you to choose the right cleaning agent for your needs!

In fact, there is a lot to bear in mind when selecting a suitable cleaner. To determine which product you need, consider the following questions for example_

- What kind of dirt is to be removed?

- What kind of surfaces and materials are to be cleaned?

- What is the size and geometry of the parts that are to be cleaned?

The NSF mark

The area in which cleaning takes place is also critical for the choice of cleaning agent. Special regulations apply in particular when cleaning production systems in the food, feed and pharmaceutical industries. All our cleaning agents are provided with the NSF mark and are thus registered and approved internationally.

The NSF registration of our cleaning agents provides users and inspectors with the reassurance that the products satisfy the regulations for food safety. NSF International is a foundation for health care. It is an independent, non-profit organisation for product testing and certification, which sets standards for a wide range of household and industrial products.

Power Force

This powerhouse removes even the most stubborn grease, oil, resin and wax both when working manually and when using a cleaning device. Also suitable for removing cooling lubricants from turning and milling centres. TIP: The cleaning power is stronger in ultrasonic, plunge bath or washing systems.

Our GARANT GreenPlus products in the field of adhesive bonding can be divided into four areas of use:

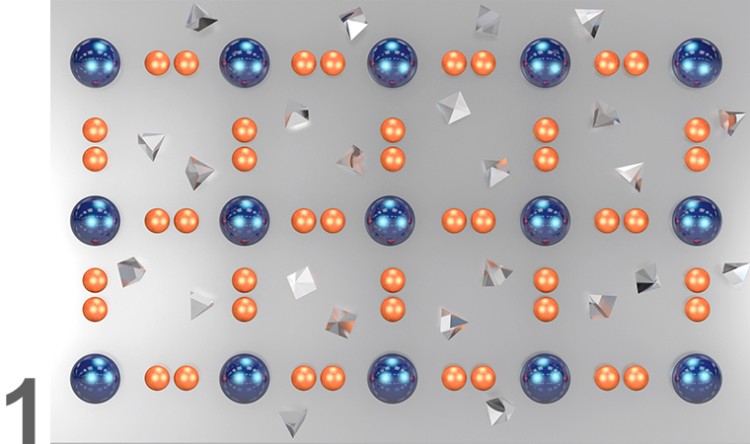

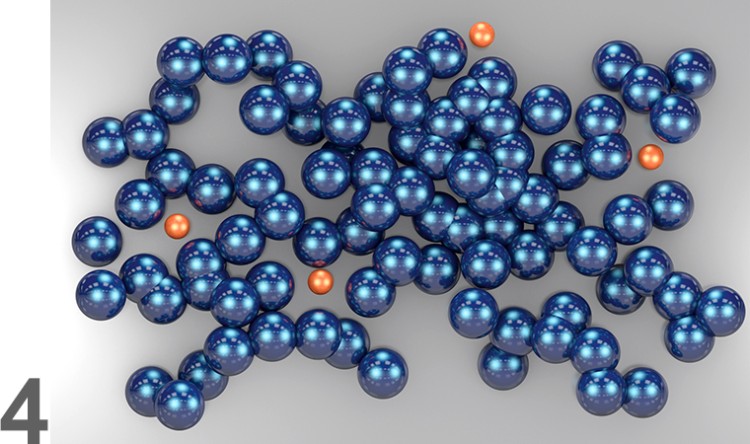

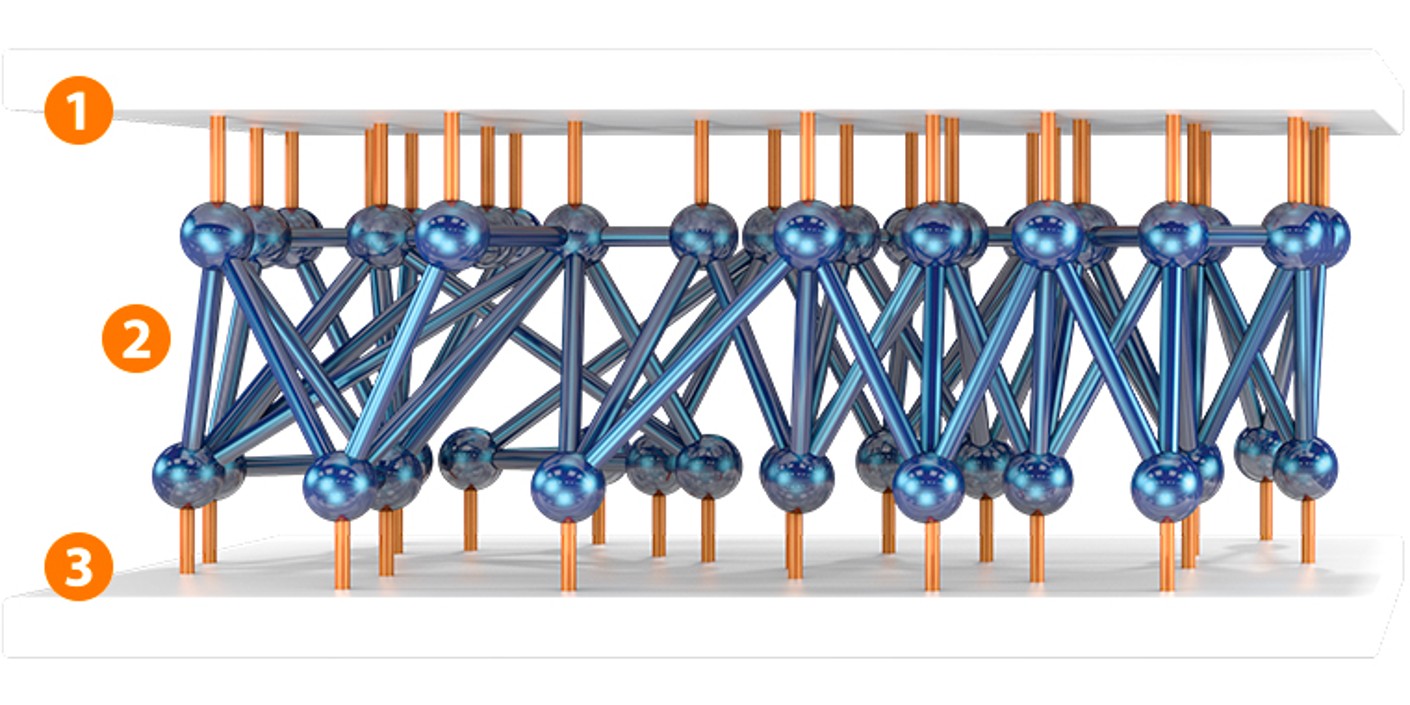

The adhesive is kept stable in the liquid state by the continuous supply of oxygen.

The adhesive is enclosed in the joint gap and thus separated from the oxygen supply.

The peroxides become free radicals with the metal ions. This initiates the formation of polymer chains.

In the hardened state, a solid structure with cross-linked polymer chains can be seen.

The power team for perfect adhesion: cleaning and adhesive bonding

Adhesives love cleanliness. The quality of adhesive bonding is ultimately dependent on the adhesion – the bond between the adhesive layer and the surface of the material – and the cohesion – the inner stability of the adhesive.

CLEANING AND ADHESIVE: The power team for perfect adhesion

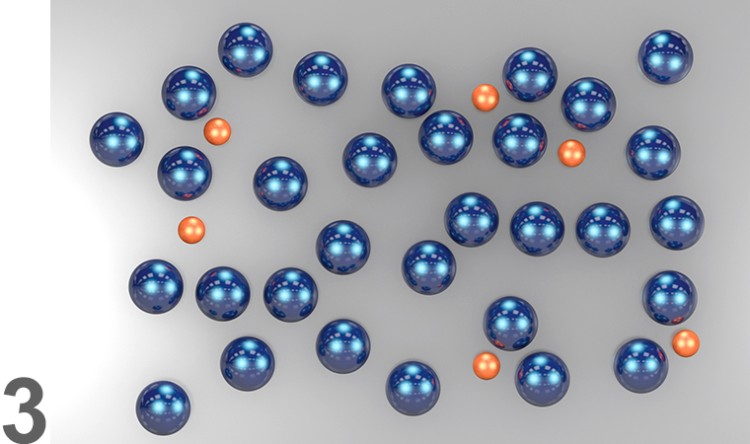

Adhesives love cleanliness. The quality of a bond ultimately depends on adhesion (bond between the adhesive layer and the material surface) and cohesion (internal stability in the adhesive).

To achieve optimum adhesion, the surfaces to be bonded must be clean, dry and free of grease.

Non-adhesive surface substances, such as dust, mould-release agents, greases or waxes, must be removed before bonding. The GARANT GreenPlus range cleaning agents help you to provide the best conditions for ensuring perfect adhesion – and hold together what belongs together!

Seal and secure – get stuck in with anaerobic adhesives!

Anaerobic adhesives are the ideal materials to use to secure screws, seal threads and create shaft-hub joints. They can withstand vibrations and even seal high-pressure lines with complete reliability.

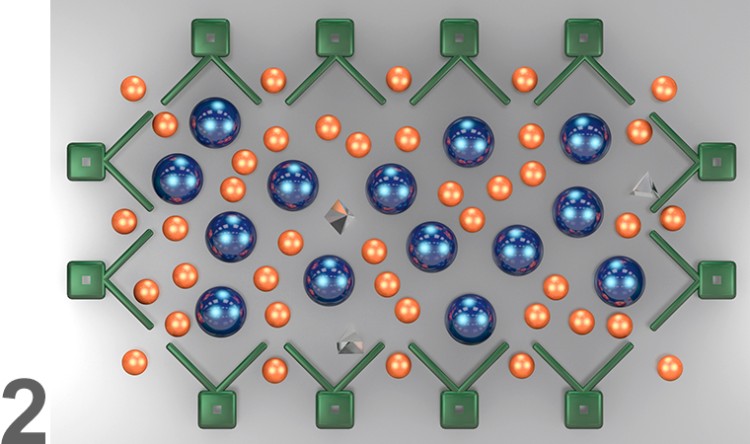

Anaerobic adhesives are single-component adhesives, that harden at room temperature when cut off from oxygen. The hardener component contained in the liquid adhesive remains inactive as long as it is in contact with oxygen. Oxygen thus prevents anaerobic single-component adhesives from hardening.

This is why bottles for anaerobic adhesives contain air and are only half-filled with adhesive. As soon as the adhesive is cut off from oxygen, e.g. by bringing together the parts to be joined, the hardening process proceeds very quickly – especially if there is simultaneous metal contact.

Anaerobic adhesives harden when cut off from oxygen and become duromers. They withstand temperatures from -55°C to approx. 180°C. A basic distinction is made between low strength, medium strength and high strength. The choice of strength class depends entirely on the application.

To the product

To the product