The motor behind digital documentation in EVUM aCAR production

Electric commercial vehicle manufacturer EVUM Motors drives the digitalisation of their quality management forwards with HCT

Evum Motors is the spin-off of a visionary research project at the Technical University of Munich.

The two founders Sascha Koberstaedt and Martin Šoltés have committed themselves to enabling quick and uncomplicated entry into the field of electric mobility wherever a small and manoeuvrable transport vehicle with an all-wheel drive is required: In the agricultural and forestry sectors, in industry and municipalities, and for tradespeople.

Since the end of 2020, the EVUM aCar has been in series production.

"We are relying on the most future-proof technologies, and not just in our EVUM aCar, but in all areas of the company. We have the advantage that we can build up our entire production using the latest technologies and standards without having to deal with obsolete legacy structures. We use the Bluetooth-capable GARANT torque/rotational angle wrenches HCT from the Hoffmann Group in quality management. These offer us outstanding functions, at an unbeatable price-performance ratio."

Gregor Fischer, production planner at EVUM Motors

Added process reliability

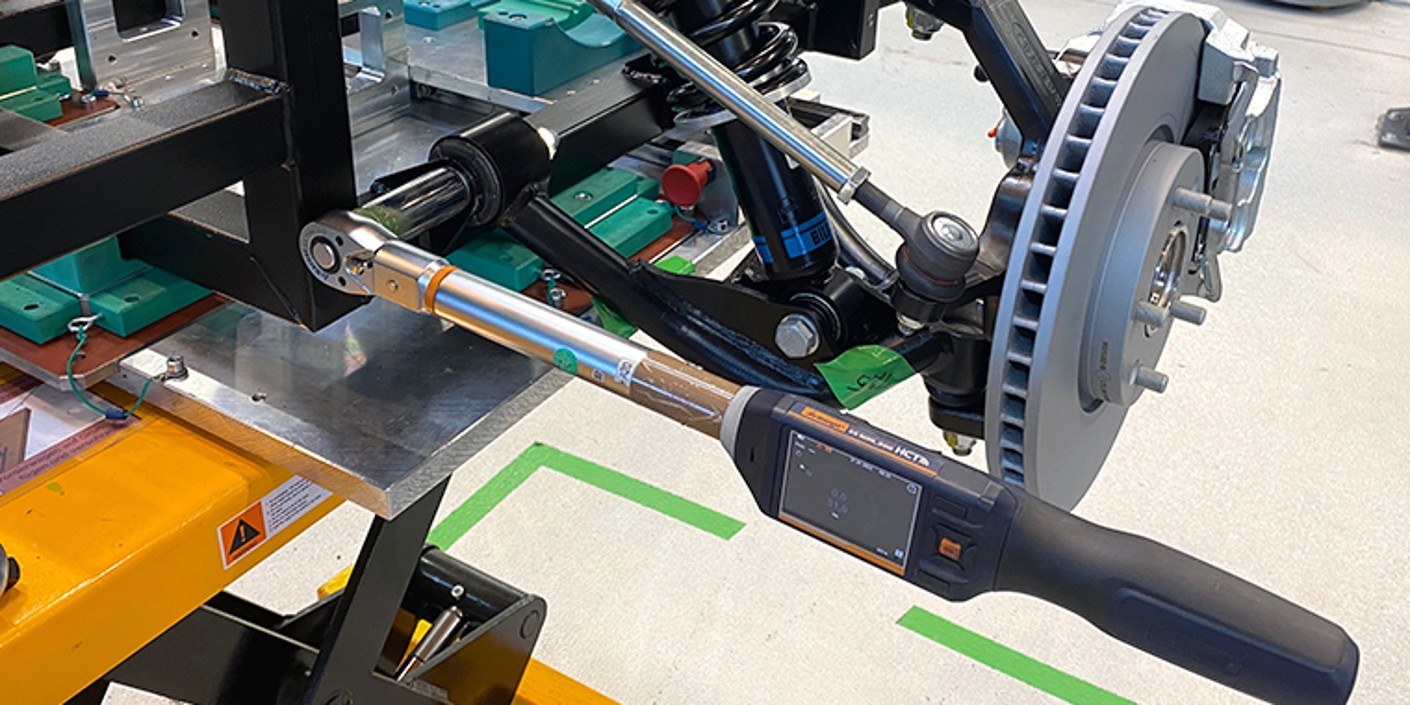

The electronic GARANT torque/rotational angle wrenches are mainly used to securely bolt together the body parts and wheels at EVUM. For each vehicle, this is around 200 bolts.

When a bolt is tightened, the tool shows the measured value on a high-contrast 2.8-inch TFT colour display with stable viewing angle. This means the employee can keep an eye on the measurement at all times. In addition, a visual signal warns them before the maximum permissible torque setting is exceeded. A warning tone and vibration mode can be switched on as an option. At regular intervals, the data is exported from the torque wrenches as a .CSV file and stored in a database.

Full integration with CAQ system planned

HCT tools and cooperation with the Hoffmann Group experts play a central role in the digitalisation of quality assurance. In the future, this will be organised by a computer-aided quality management system (CAQ).

"For us it is a real advantage that, with the HCT tools, we can already transfer data wirelessly and thus increase process reliability," says Fischer. "The Hoffmann Group has developed a Windows app to make data transfer to a PC even faster. We are testing this as a pilot customer. With this, we can send data from several HCT tools simultaneously. The Hoffmann Group isn’t just a supplier for us, but a good sounding board."

"We want to create a link between the tool and the CAQ system with the HCT Windows app. For example, it will be possible to create screw tightening profiles (external, text-based with XML) or download them from the wrenches and transfer them to the various HCT torque wrenches. We are also planning that, in the future, complete work procedures will be created and controlled across multiple HCT tools using the Windows app and, through CAQ system integration, a link between tool, measurement data and workpiece can be established."

Marko Künstler, Senior Project Manager at the Hoffmann Group

Digitalise measuring processes with ease thanks to the electronic GARANT torque wrench

The electronic GARANT torque/rotational angle wrench HCT is part of the Hoffmann Group Connected Tools (HCT) open platform for digital quality management. The Hoffmann Group is driving digitalisation forward in the tooling sector through HCT. The Bluetooth-capable HCT tools allow measurement data to be sent wirelessly to smartphones, tablets or PCs at the touch of a button, where they can then be saved and managed. The Hoffmann Group developed the HCT Mobile app and the HCT Windows app especially for this.

Bluetooth-capable products from HOLEX, Mitutoyo, Bowers Group and Sylvac are also now compatible with the HCT mobile app. This includes dial indicators, vernier callipers and torque wrenches along with 3-point internal micrometers. As a result, tools for many different measuring operations are available to the quality management team in the workshop and production department.