Broaching in perfect form

Stable and precise for more productivity in turning work

Discover GARANT broaching.

Achieve very high precision with low tooling costs and low set-up costs.

Very wide variety: Cutter inserts for slot widths from 2 - 25 mm (normally only up to 14 mm available on the market). Available in tolerances C11, D10, H7 and P9. Slot generation can be performed to DIN 6885-1, DIN 138 and factory standard.

Productivity due to extra strong cutter inserts: Increased stability and process reliability.

6.5 - 18 mm (normally only up to 6 mm available on the market). Sintered steel alloy (70 HRC), 13% cobalt, TIN-coated.

Broaching - Advance into new dimensions

GARANT Nutenstossen

Mit/ohne Fase, vierkant und sechskant.

- Wide product range

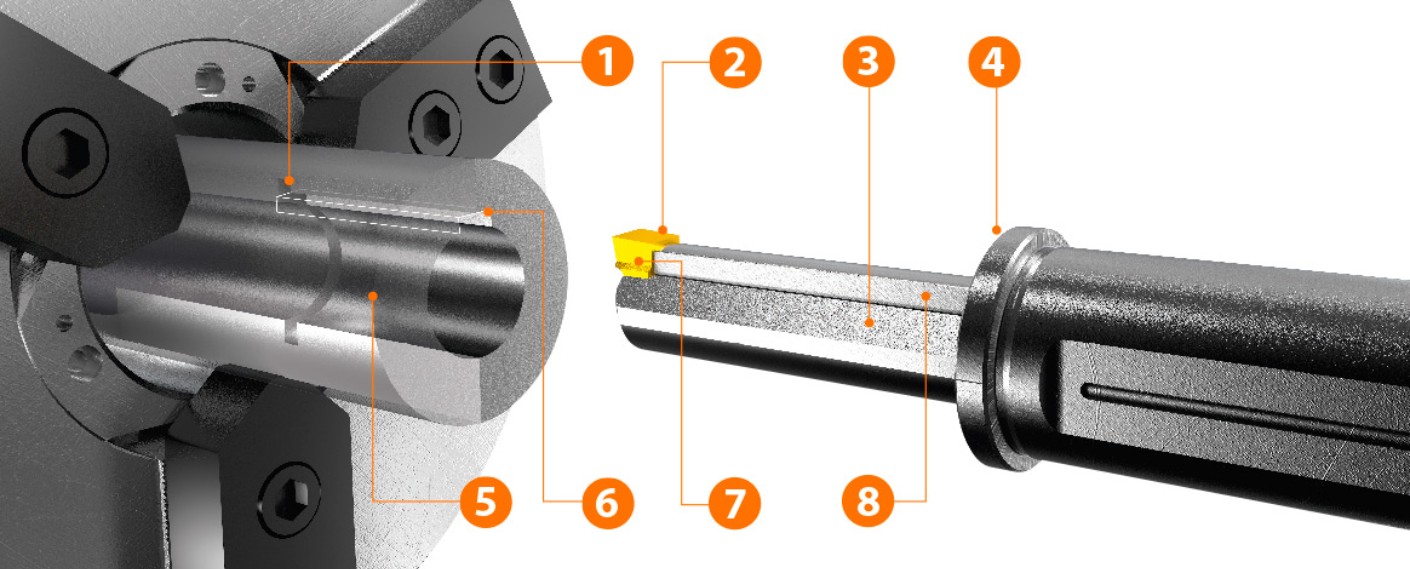

Standard and long version. Working length of 25 - 200 mm. - Customised solutions

Available on request on short lead times. - Two cooling channel bores

Optimisation of chip evacuation. Increased surface quality. Cooling of the cutters. - Stable tool design

Insert seating hardened (58 - 60 HRC). Optimum seating of the cutter insert due to 4-point contact. Centring by Vee shape. Maximum support and continuous backing for highest stability.

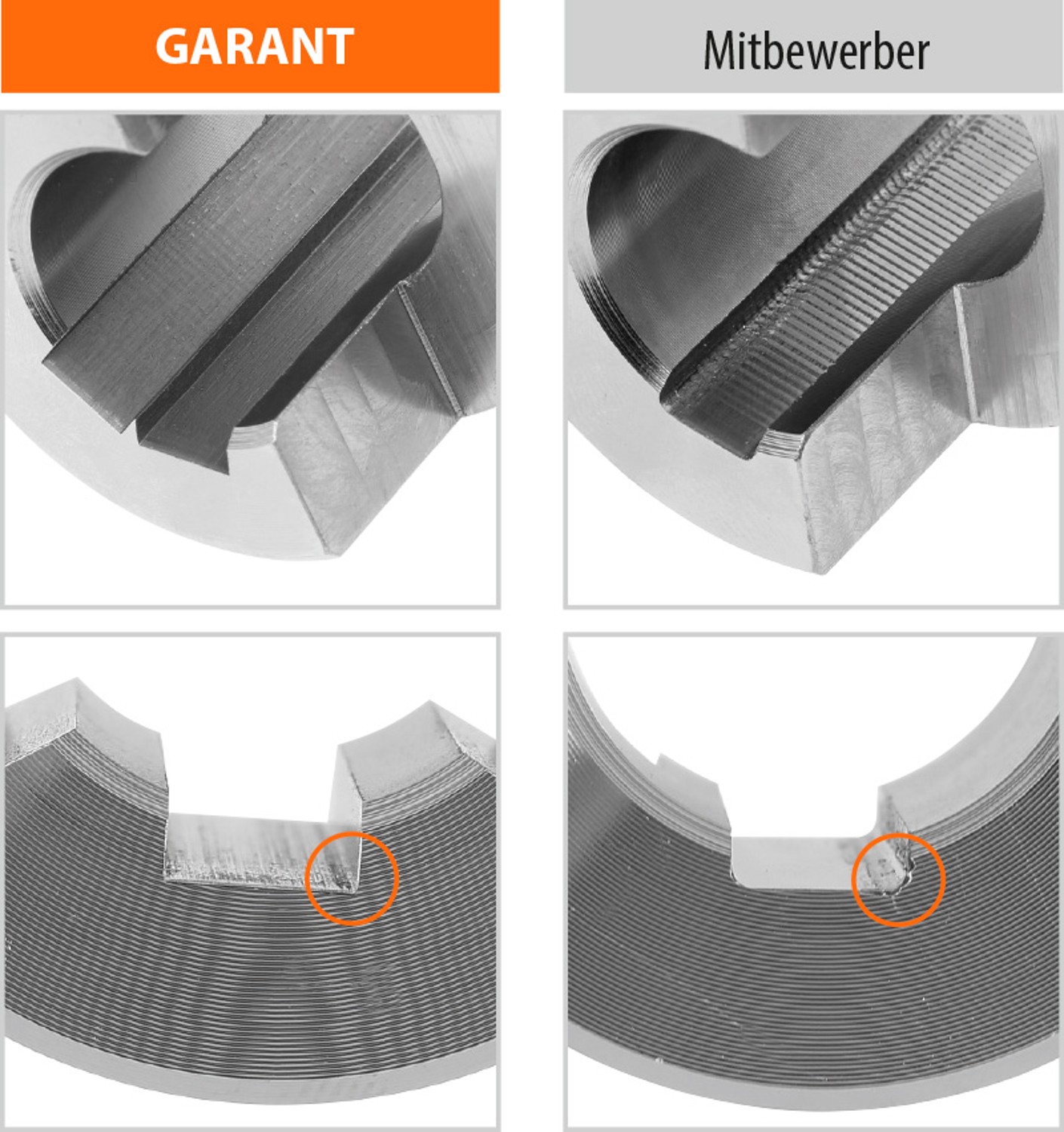

Superior to the competition when making direct comparisons.

An analysis of machining forces by the Forschungs- und Transferzentrum e. V. (Research and Transfer Centre) confirms uniform force progression for GARANT broaching. Additionally, the quality of the workpiece surface remains consistently good.

Left column GARANT:

Smooth slot as well as sharp edges and exact corners with GARANT.

Right column competitor:

Clear chatter marks and inexact corners.

Uneven machining forces.

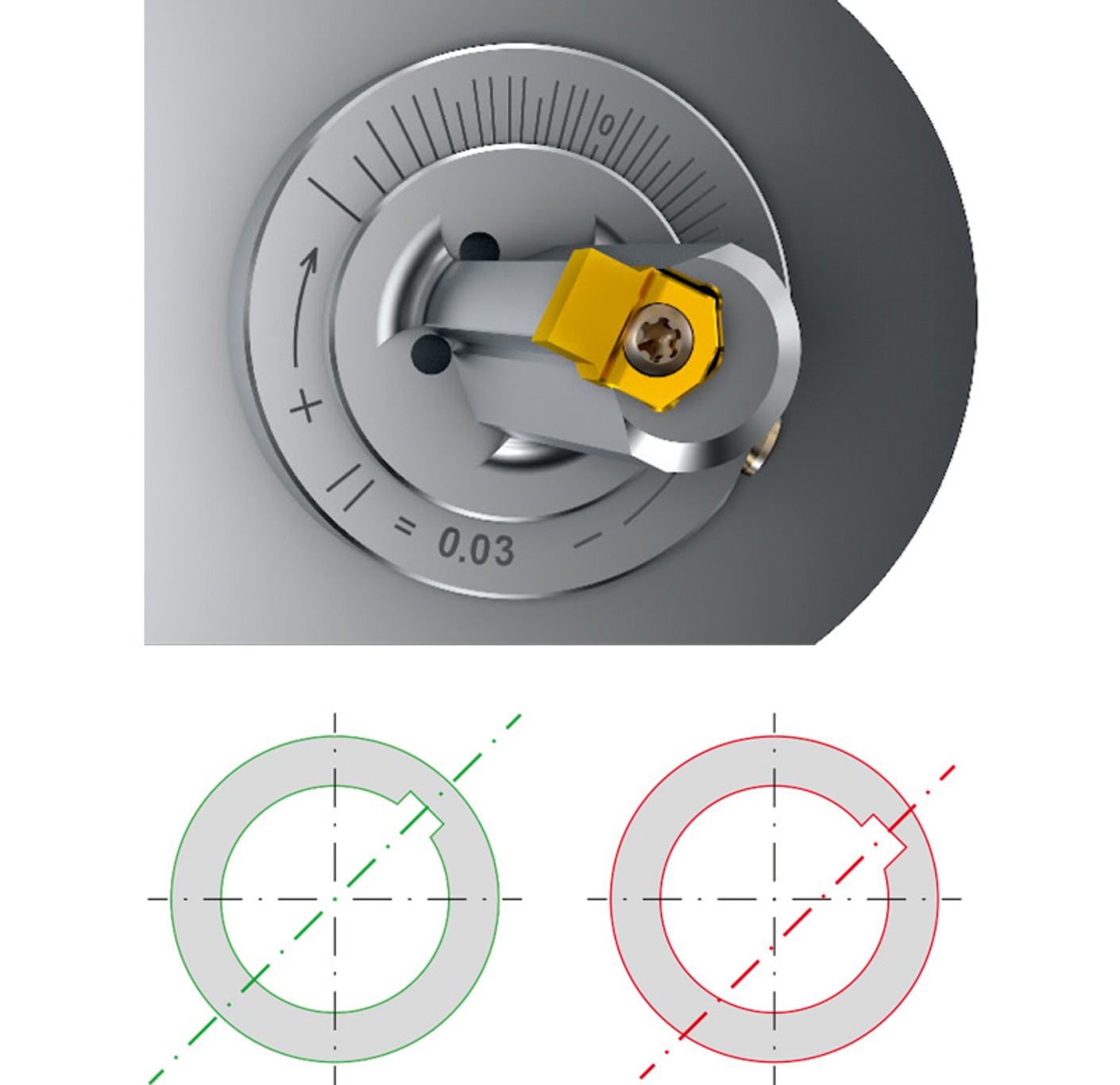

Highest precision – even without a Y-axis.

All slots can be generated on a conventional CNC lathe. The highest standards of fit, slot profile and width require a lathe with a Y-axis or just the special patented eccentric bush for the broaching toolholder.

Inaccuracies due to tolerance chains can lead to symmetry errors.Uncomplicated and quick correction of the y-axis is possible by turning the eccentric bush (s. image at the top, right-hand side).

Advantages GARANT broaching

The advantages of GARANT broaching:

- Clean slot. Sharply cut edges without burrs. Cutting inserts can also include a chamfer. (Broaching into a blind hole requires a suitable relief groove!)

- Avoidance of cutter breakage. Sintered steel alloy with 13 % cobalt. (Programme a lead-in travel of 15 mm!)

- Ideal application of force and easy clearance of the swarf. (Install the tool overhead!)

- Two cooling channel bores for wet machining. Better surface, better chip evacuation and protection of the cutter.

- Guaranteed dimensional accuracy when the eccentric bush is used. (Idle stroke at the end of the cut!)

- Lower cutting forces due to durch the highly positive cutter geometry. (From slot width 16 mm, cut the slot in two passes (1/2 slot width!))

- Avoidance of scores on the return stroke. The least possible bore Ø (the holder must suit the slot width).

(During the return stroke in X-axis lift the cutter completely out of the slot!) - Reduction of vibration due to full length support. (Clamp on the shortest mounting!)

Product video

GARANT broaching

GARANT broaching means more productivity in turning. The range extends from stable tool designs through to special solutions on short lead times.

Small modifications - big impact: this film will show you tips and tricks relating to the subject of broaching and how you can achieve very high precision with low tooling and set-up costs.

Tools in Action Video

GARANT Nutenstoßen in Anwendung! Für eine bessere Aufnahme verzichtete man ausnahmsweise auf eine Kühlung - und dennoch zeigte der Schneideinsatz in 16MnCr5 keinerlei Gebrauchsspuren.