Version:

Cutting chisel edge with high centring accuracy due to strong core and special point geometry.

Particularly high alignment accuracy due to 4 guide chamfers which stabilise the drill even at extreme depths!

Convex cutting edges with honed edges and special flute profile for short chips, even on long chipping materials.

Advantage:

High process reliability and surface quality of the hole.

Note:

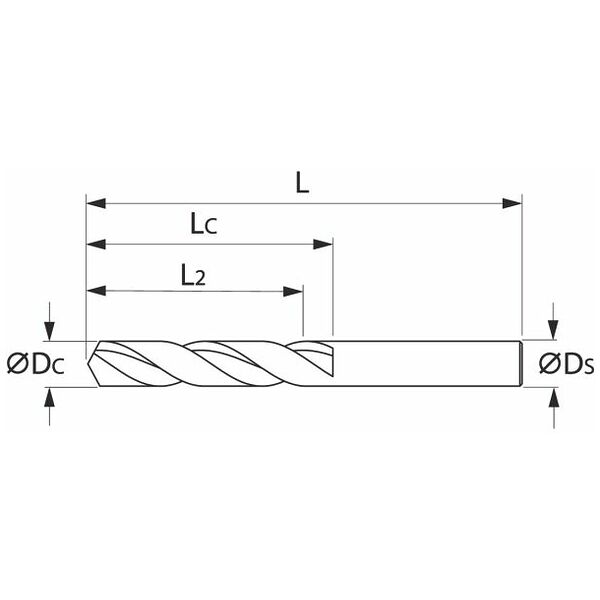

Flute length L

C = L

2 + 1.5 × D

C.

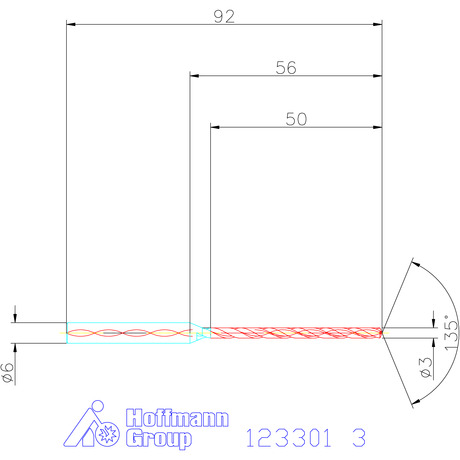

For process reliability when using the 12×D drill, an initial centre drilling with NC spotting drills No.

121068 –

121130 is necessary.

Form HB and HE are supplied at the same price as HA.

Form

HB: order with

No. 123302.

Form

HE: order with

No. 123301 + 129100HE.

NEW GENERATION AVAILABLE!Recommended successor products are No. 123225 and 123235.