Version:

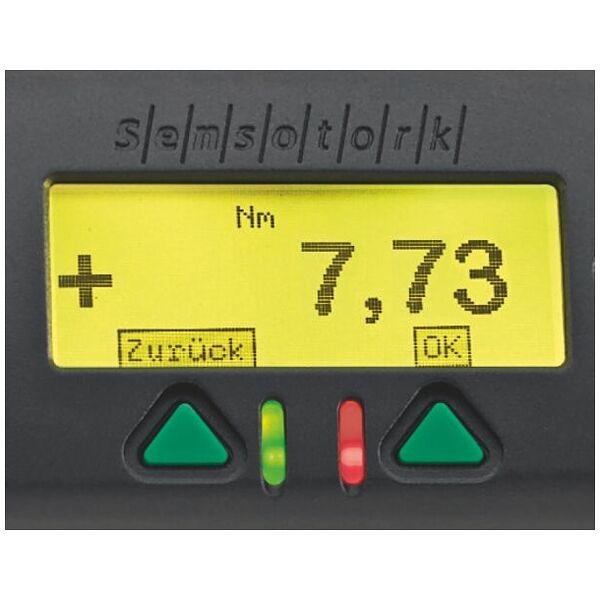

The torque/rotational angle wrench offers easy and flexible operation with menu selection on a large display. Recurrent screw settings can be collected on to a menu driven procedure. The early warning of the

visual, tactile and acoustic signals is adjustable. Resistant to oils, grease, fuel, brake fluid and Skydrol. The wrench is easy to maintain due to simple adjustment, can be programmed via a PC and offers a large measurement range. Password input ensures protection against unintentional adjustment and external access. Torque and rotational angle both displayed at the same time. Rotary angle measurement can be programmed easily, no reference arm required.

- Robust, compact body.

- Easy and flexible operation with menu selection on a large display.

- Recurrent screw settings can be collected on to a menu driven procedure.

- Especially large measuring range (5% − 100% of the nominal value).

- Adjustable early warning of the visual, tactile and acoustic signals.

- Resistant to oils, grease, fuel, brake fluid and Skydrol.

- Programmable using a PC.

- Easy to maintain due to simple adjustment.

- Integrated automatic reminder of calibration after the number of operations and elapsed time.

- Password protection against inadvertent change of settings and tampering.

- With 2 batteries (1.5 V mignon / AA / LR6).

- Torque and rotational angle both displayed at the same time.

- Convenient rotation angle measurement, no need for a reference arm.

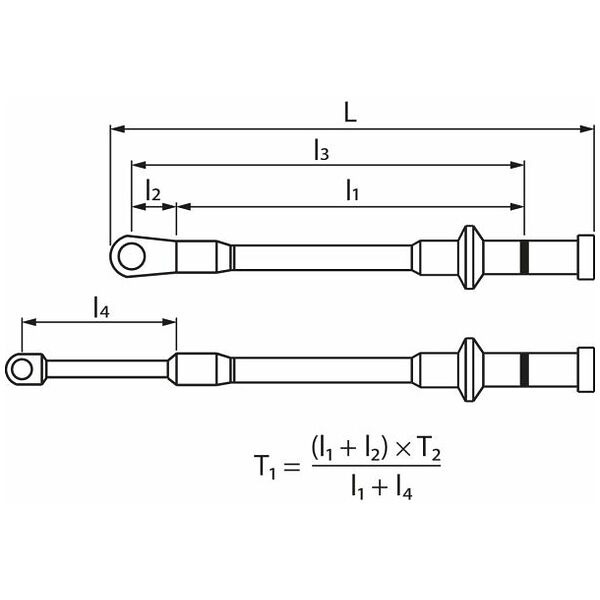

- Easy input of reference: For plug-in heads with a different reference dimension, simply input the new dimension. No laborious calculations with formulae.

- QuickRelease: Secure fit and quick change for plug-in heads.

- Rotation angle measurement needs no reference arm.

- Easy to use: The arrow keys allow all functions to be selected. Clear and simple controls.

- Automatic reminder of calibration: After the number of operations and elapsed time.

- Warning signals: Warning signals can be selected as acoustic (buzzer), tactile (vibration in the handle), visual (LEDs and display) or any combination of these. The early warning point can be entered individually.

- Any point of application of force: The measurement remains precise in all cases, irrespective of where you grip the torque wrench.

- Data output: The USB interface allows the saved data to be exported and analysed via PC.

- Background illumination of the display for better legibility and evaluation of the screwing process (traffic light principle).

Units of measure: Nm, lbfft, lbfin.

Standard:

Tested to DIN EN ISO 6789.

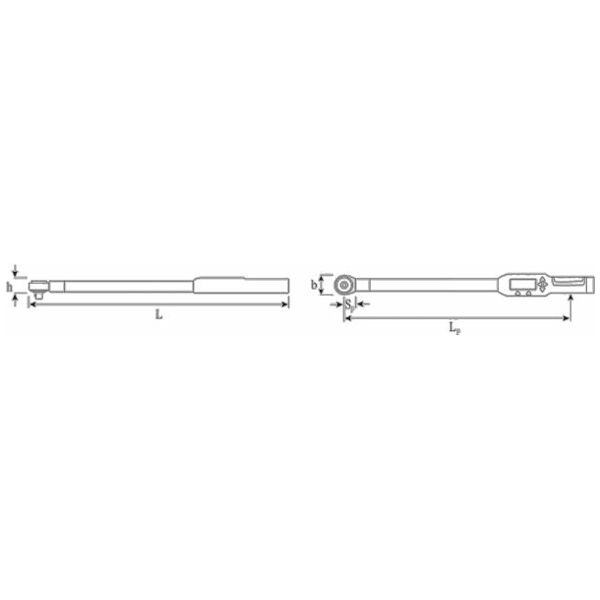

Cutting data:

Legend for drawing and formula:

l1 = Lever length without plug-in head

l2 = Adjusted reference dimension on the torque wrench

l3 = Lever length including factory calibration reference dimension

l4 = Reference dimension of the plug-in head

L = Total length of the tool

T1 = Torque to be set

T2 = Specified torque

Supplied with:

Sturdy plastic box (size 400 in sturdy sheet metal box) and 2 batteries (1.5V mignon / AA / LR6).

Optional extras:

USB adapter, cable with latching plug and SENSOMASTER 4 software.

Note:

The guaranteed measuring accuracy of the torque is achieved only once the torque range has been calibrated to DIN EN ISO 6789.